Landing section cable laying system and laying method

A technology of cable laying and landing section, applied in the direction of cable laying equipment, etc., can solve the problems of limiting the speed of cable pulling, increasing the workload of manpower, and shortening the time of cable laying operations, so as to avoid time constraints and increase operation time , The effect of reasonable arrangement of construction time and work and rest time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

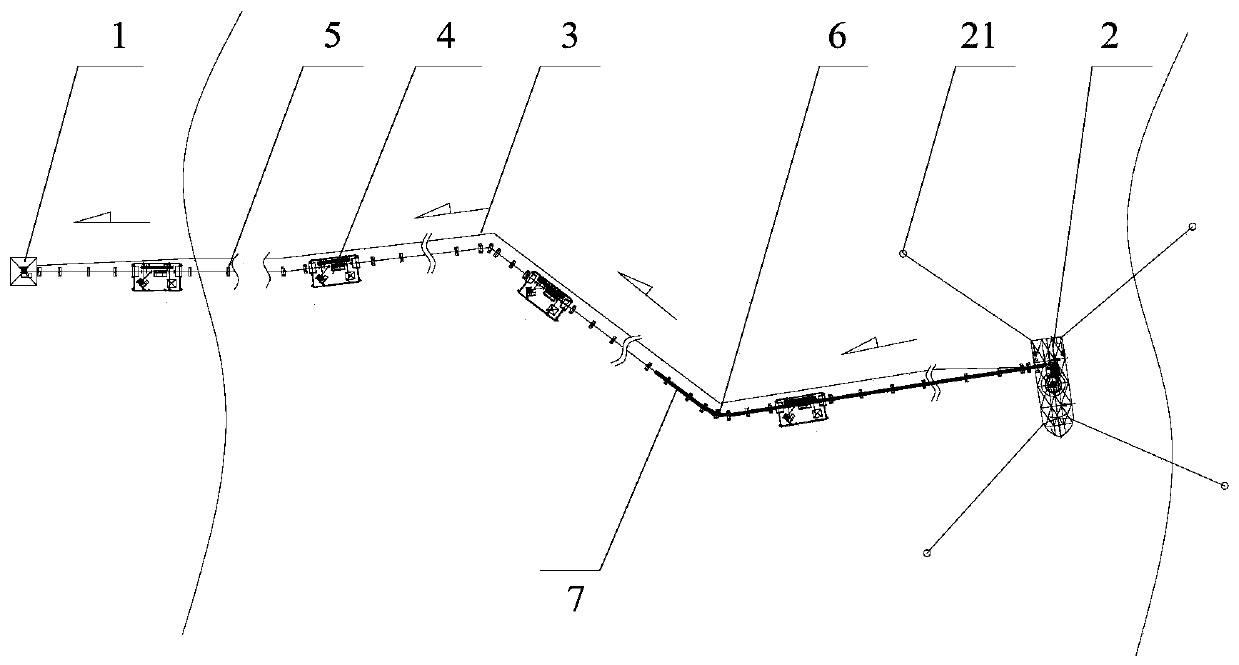

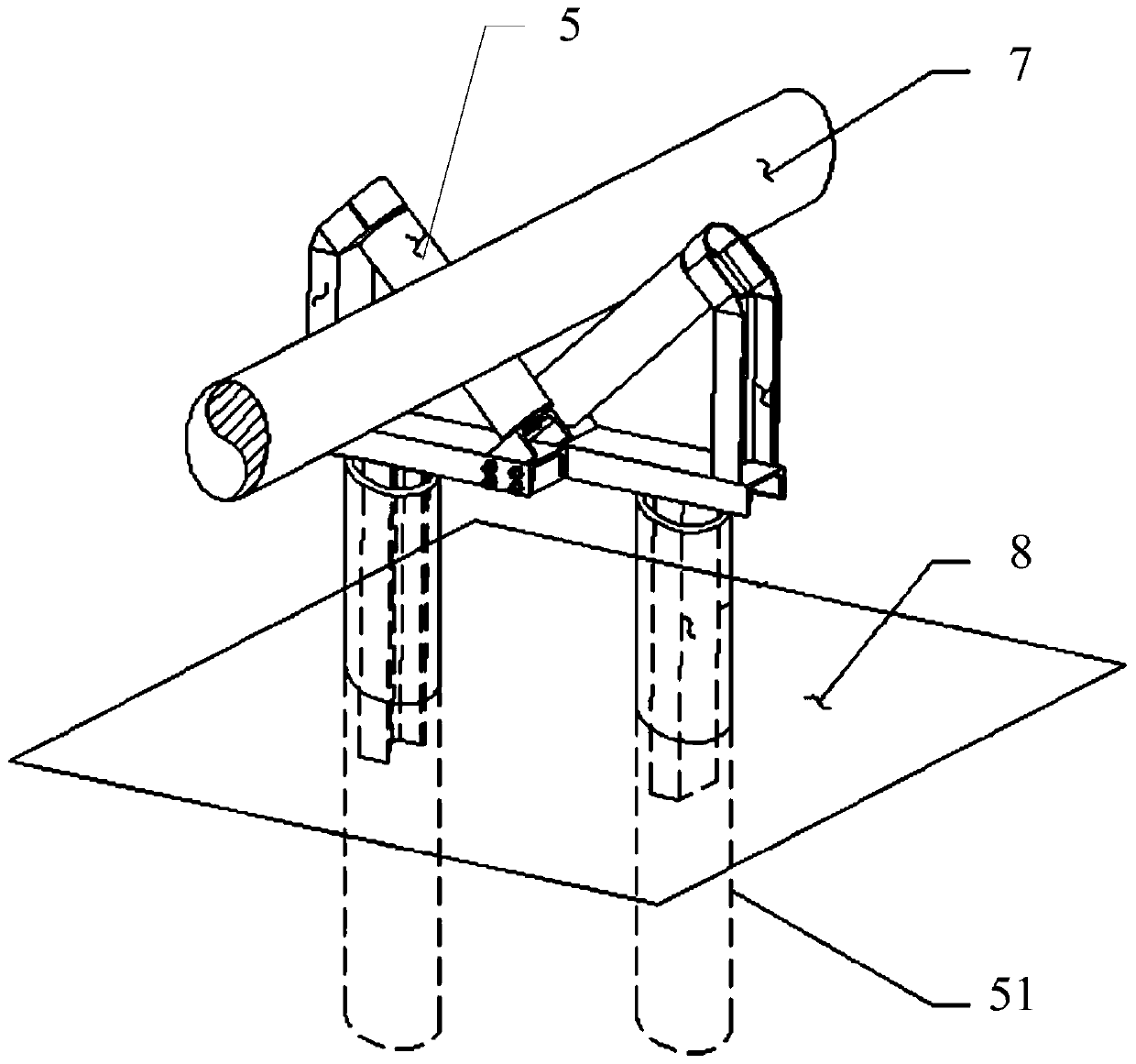

[0071] like figure 1 , 3 As shown in -4, a cable laying system for the landing section provided by the present invention includes a land terminal 1, a cable laying ship 2 and a plurality of cable pulling brackets, and the lower end of each cable pulling bracket is a pipe pile 51, which is used for Fixed in the soil interface 8, the upper end is provided with a bracket structure for supporting the cable 7; a plurality of cable pulling brackets are arranged at intervals along the cable design route 3 connecting the land terminal 1 and the cable laying ship 2, forming a cable pulling bracket. Pulling channel; the cable pulling channel includes a plurality of straight segments, and a broken line is formed between a plurality of straight segments; a pulling device 4 is arranged at each straight segment of the cable pulling channel, so The pulling device 4 is used to pull the cable 7 from the cable laying ship 2 to the direction of the land terminal 1 .

[0072] In this embodiment...

Embodiment 2

[0088] The present invention provides a cable laying method for the landing section, which has the above-mentioned cable laying system for the landing section, including the following steps:

[0089] (1) At low tide, set up a cable pulling channel, install pulling device 4 and land terminal 1;

[0090] (2) When the tide is high, the cable laying ship 2 is positioned;

[0091] (3) At the next low tide, start the laying system of the cable laying ship 2, so that the end of the cable is lowered to the end of the cable pulling channel close to the cable laying ship 2;

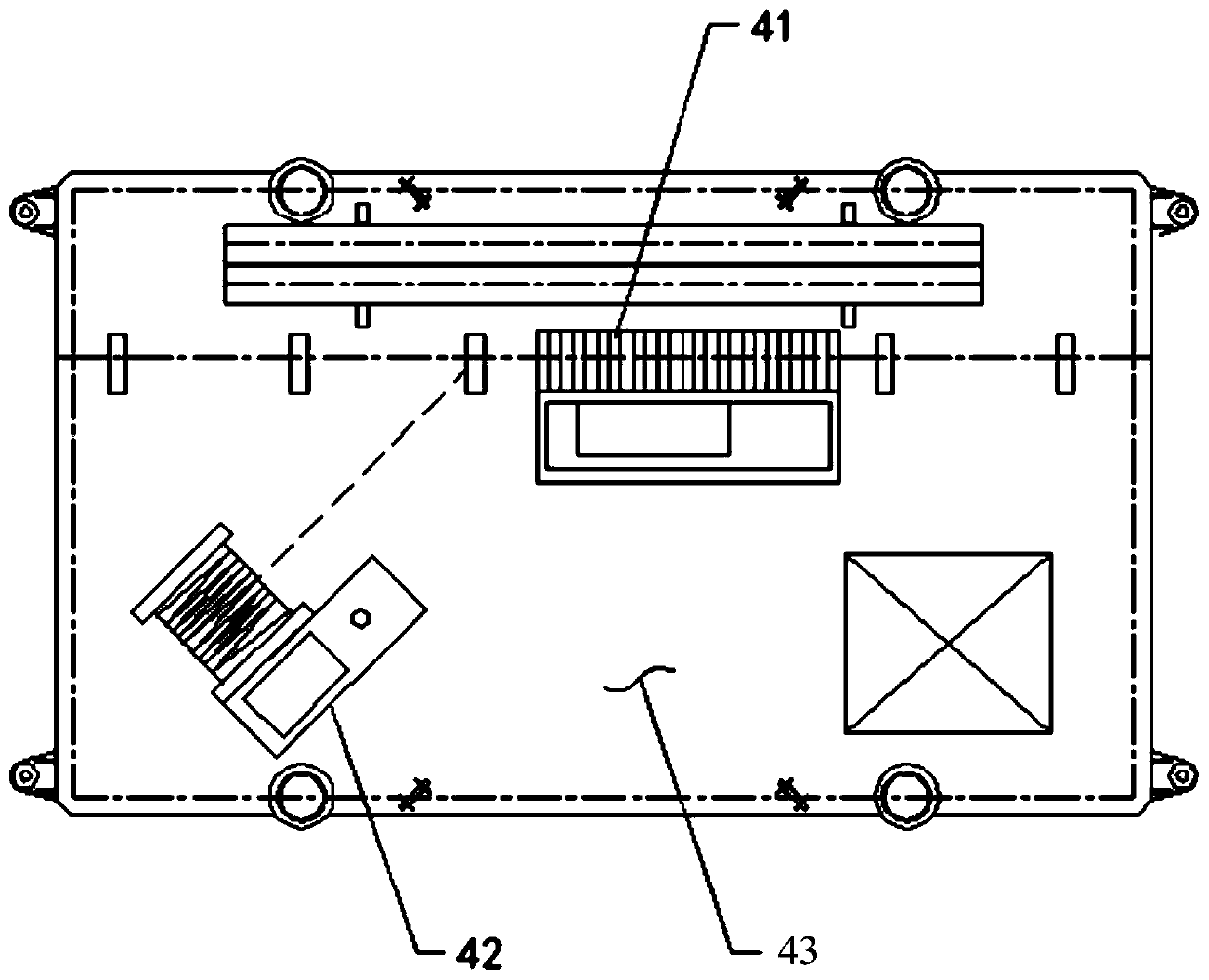

[0092] (4) pull the twisted rope of the winch mill 42 on the first pulling device 4 to the cable end of the cable laying ship 2 along the cable pulling passage, and connect with the cable end;

[0093](5) Start the winch 42, pull the end of the cable to the first pulling device 4 along the cable pulling channel, and enter into the first pulling device 4 On tractor 41;

[0094] (6) move the movable end of the twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com