Cotton coating type rooting agent as well as preparation method and application thereof

A rooting agent and coating technology, which is applied in the agricultural field, can solve the problems of cumbersome seedling operation procedures, increased investment and cost, etc., and achieve the effects of low shedding rate, shortened seedling growth, and good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

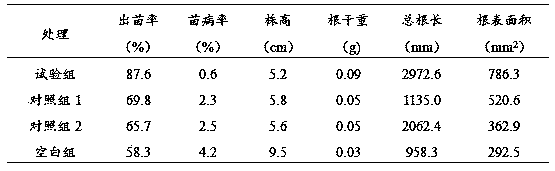

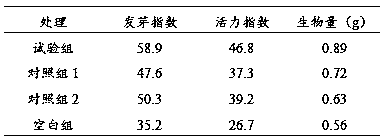

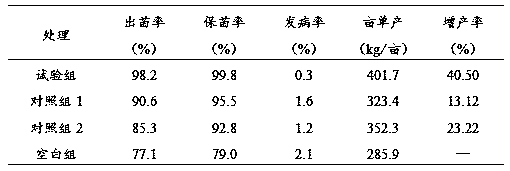

Examples

Embodiment 1

[0019] A cotton-coated rooting agent, prepared according to the following weight percentages and steps (100 kg): 0.01% 28-homobrassinolide, 1.52% nitazoxanide, 2.75% kanodol, 0.5% mannitol, 2.6% Antioxidant 1010, 4.8% oat B-glucan and 5% complex film former (SY-201:SY-202=1:1), the balance of water.

[0020] Dissolve nitazoxanide, antioxidant 1010 and oat B-glucan in water respectively and mix them, then add candolol, mannitol, compound film-forming agent and the rest of water in turn, stir well, coarsely grind, finely grind, to get the finished product.

Embodiment 2

[0022] A cotton-coated rooting agent, prepared according to the following weight percentages and steps (100 kg): 0.005% propionylbrassinolide, 1.7% nitazoxanide, 3% kandol, 1% mannitol, 3 % Antioxidant 1010, 5.5% oat B-glucan and 6% complex film former (SY-201:SY-202=1:1), the balance of water.

[0023] Dissolve nitazoxanide, antioxidant 1010 and oat B-glucan in water respectively and mix them, then add candolol, mannitol, compound film-forming agent and the rest of water in turn, stir well, coarsely grind, finely grind, to get the finished product.

Embodiment 3

[0025] A cotton-coated rooting agent, prepared according to the following weight percentages and steps (100 kg): 1% 22,23,24-epibrassinolide, 3% nitazoxanide, 5% candophenol, 1.5 % mannitol, 5% antioxidant 1010, 10% oat B-glucan and 7% complex film former (SY-201:SY-202=1:1), the balance of water.

[0026] Dissolve nitazoxanide, antioxidant 1010 and oat B-glucan in water respectively and mix them, then add candolol, mannitol, compound film-forming agent and the rest of water in turn, stir well, coarsely grind, finely grind, to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com