Grinding device and grinding method for pig iron casting

A technology of pig iron castings and grinding rollers, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc., can solve the problems of inability to realize metal waste recycling, increase the workload of staff, and complicated equipment installation, etc., to achieve Reduce the number of repeated grinding, reduce the workload, improve the effect of grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

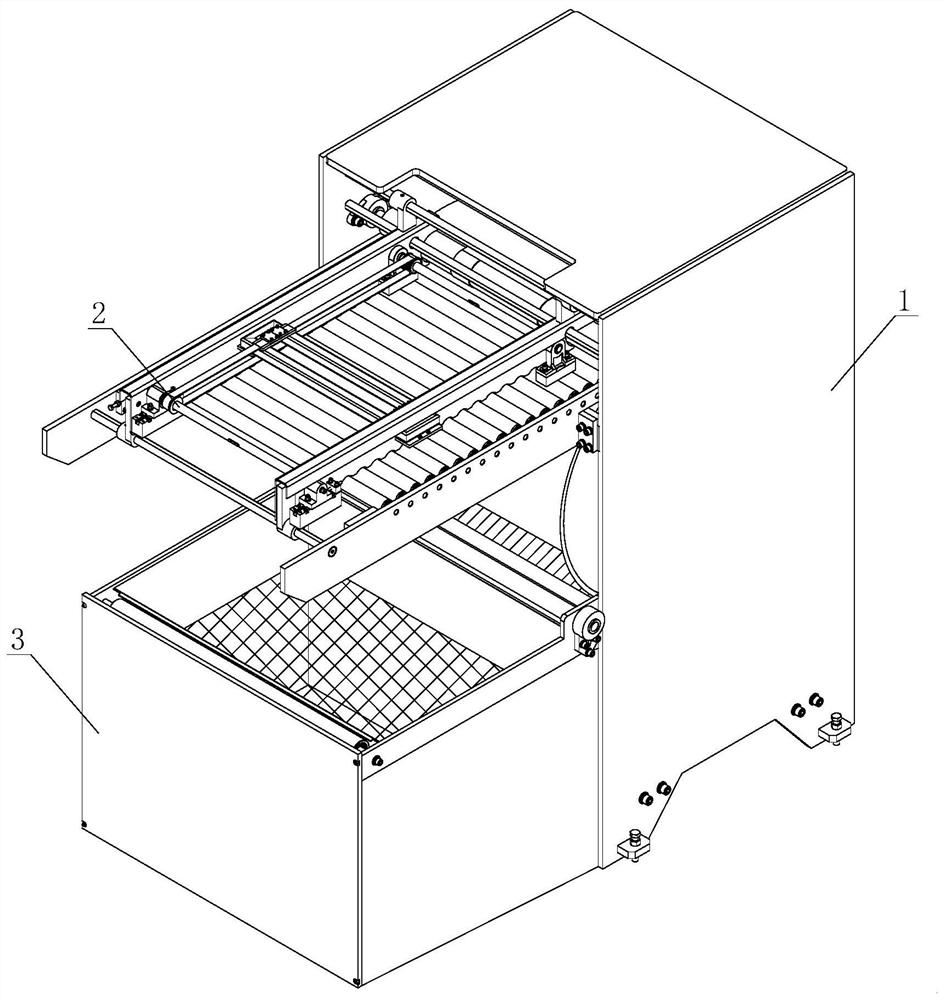

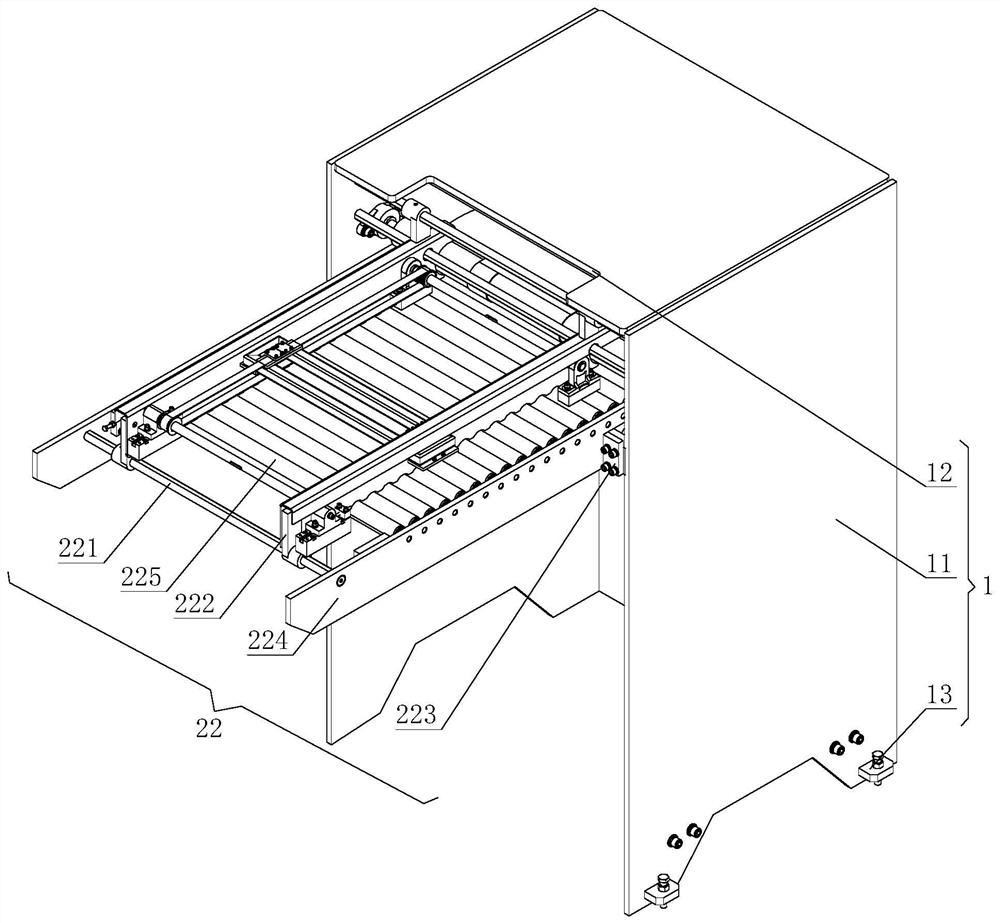

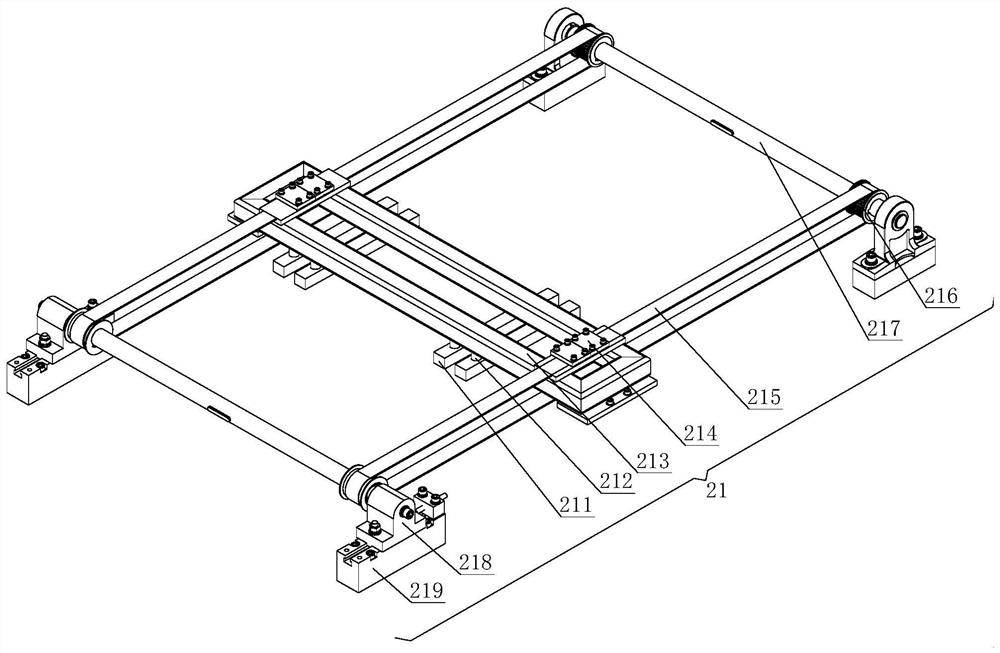

[0028] See figure 1 , A casting device of a cast iron casting includes a mounting tank 1, a grinding apparatus 2, and a vacuum cleaner 3, and the inside of the mounting tank 1 is fixedly mounted, and the dust collecting device 3 is located below the grinding device 2, The mounting tank 1 includes a casing 11, a shaded mounting groove 12, and a bracket 13, and the strip frame 13 is fixedly mounted at the bottom of the outer wall of the casing 11, and the top processing of the casing 11 is moving the mounting groove 12, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com