Stator processing device

A processing device and stator technology, which is applied in the manufacture of stator/rotor body, etc., can solve the problems of plugging wear, iron filings flying, production environment impact, etc., so as to improve service life, reduce iron filings and dust content, prevent iron The effect of chips entering the assembly hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

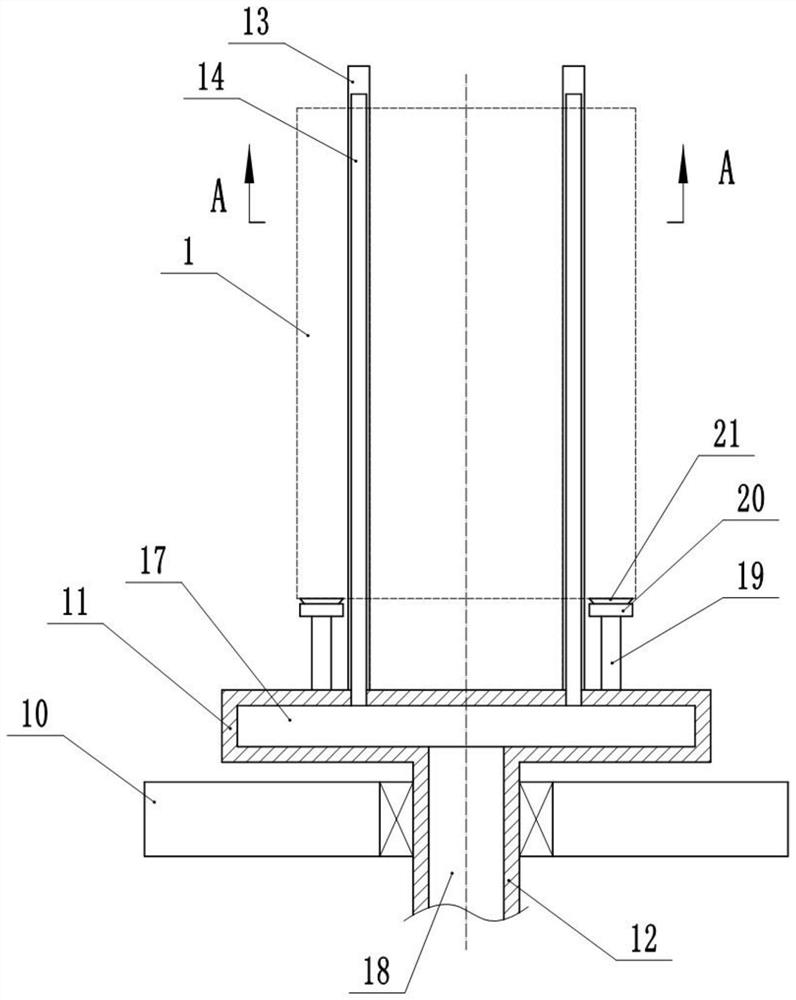

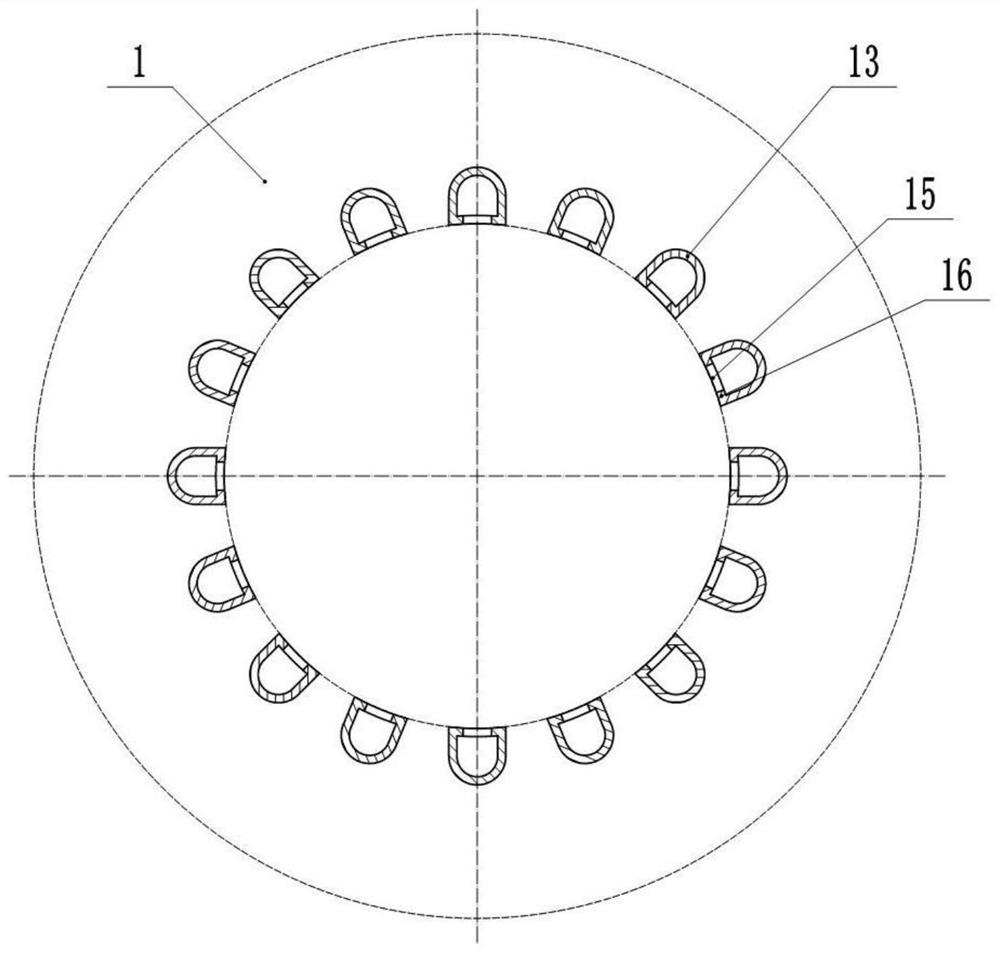

[0022] The embodiment is basically as figure 1 and figure 2 As shown, the stator processing device includes a support unit, an adsorption unit and a grinding unit, wherein the support unit includes a workbench 10 and a support plate 11, the bottom of the support plate 11 is coaxially fixed with a main shaft 12, and the main shaft 12 is rotatably connected to the workbench 10, A driving assembly for driving the main shaft 12 to rotate is also provided below the workbench 10 .

[0023] On the supporting plate 11, some blocking rods 13 are fixed, and the cross-sectional shape of the blocking rods 13 is the same as the shape of the assembly hole on the stator to be polished. A cavity 14 is provided in the blocking rod 13 along its length direction, and a strip slit 15 connecting the cavity 14 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com