A flow transition passive control device using surface openings/grooves

A transition and micro-grooving technology, applied in the field of aerodynamics, can solve the problems of frictional resistance, noise heat flow and mixing difference, too small hole or groove size, poor robustness, etc., to improve absorption efficiency and reduce friction. The effect of high resistance and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

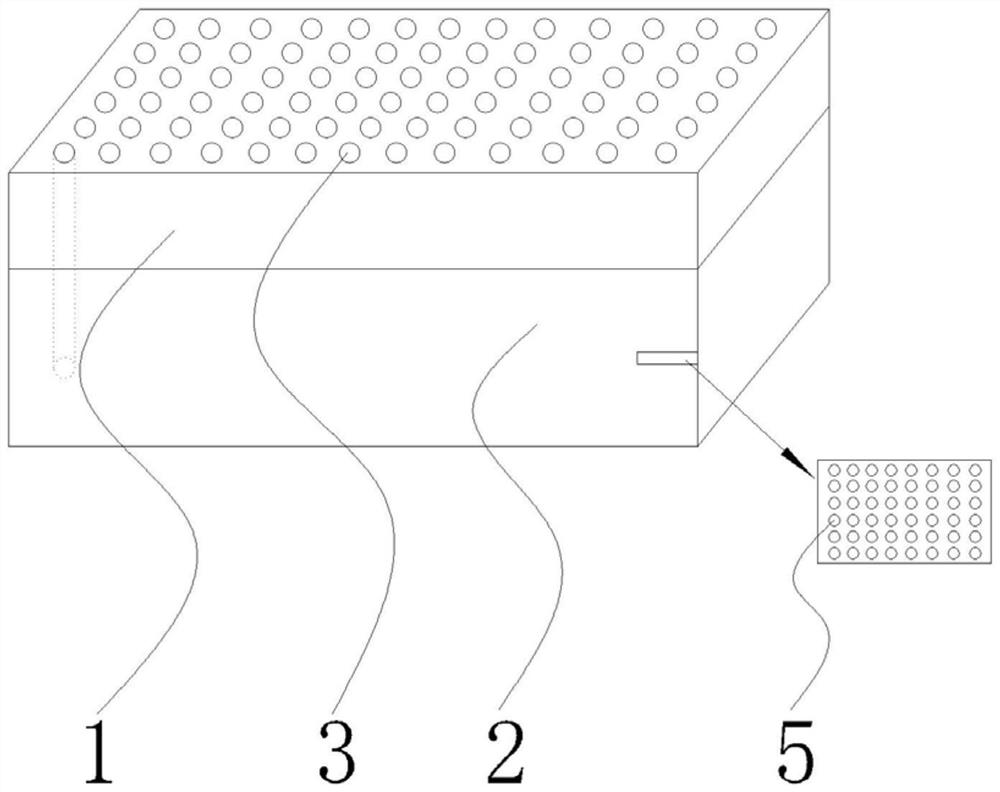

[0028] Such as figure 1 As shown, a flow transition passive control device using surface openings / grooves in this embodiment includes an upper layer of metal material layer 1 and a lower layer of sound-absorbing material layer 2, the thickness of the metal material layer 1 is 1mm, and the sound-absorbing material layer The thickness of layer 2 is 4 mm; the surface of the flow transition passive control device is provided with micropores 3 regularly distributed on the surface. The micropores 3 penetrate the metal material layer 1 and extend to the sound-absorbing material layer 2. The micropores 3 are open at the top and closed at the bottom. The structure has a circular cross-section, a depth of 3.5 mm, and a diameter of 200 μm; the sound-absorbing material layer 2 is made of a porous sound-absorbing material, and the sound-absorbing material layer 2 has a large number of micropores 5 penetrating through it.

Embodiment 2

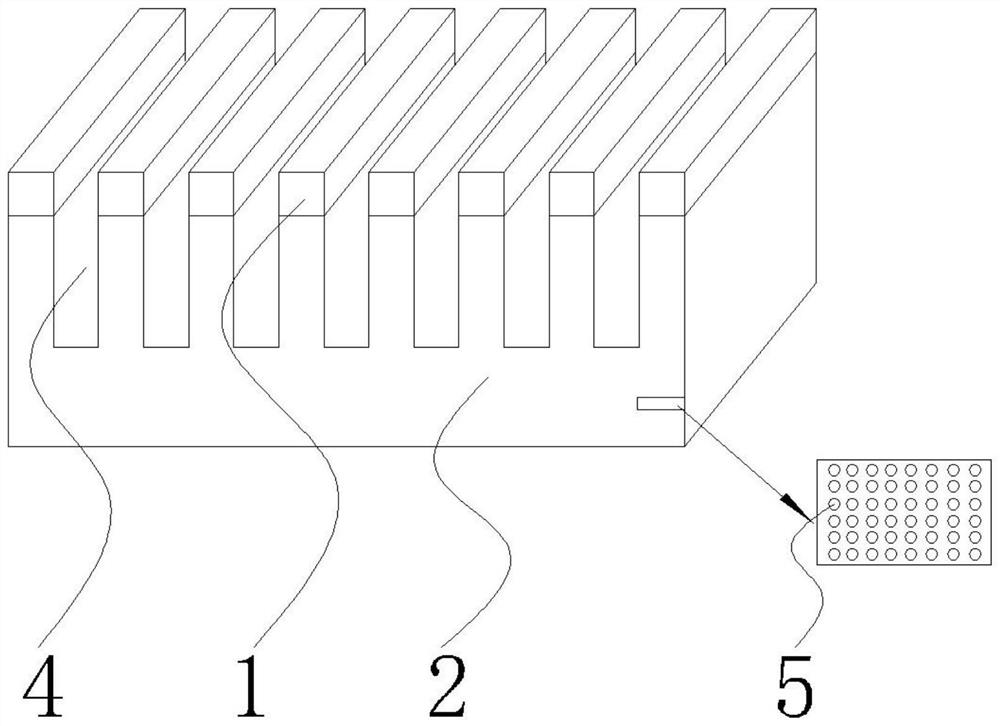

[0030] Such as figure 2 As shown, a flow transition passive control device using surface openings / grooves in this embodiment includes an upper layer of metal material layer 1 and a lower layer of sound-absorbing material layer 2, the thickness of the metal material layer 1 is 0.4mm, and the sound-absorbing The thickness of the material layer 2 is 0.6mm; the surface of the flow transition passive control device is provided with microgrooves 4 regularly distributed on the surface, the microgrooves 4 penetrate the metal material layer 1 and extend to the sound-absorbing material layer 2, and the microgrooves 4 are open at the top. The structure with a closed bottom has a rectangular cross-section, the length direction of the microgroove 4 is perpendicular to the fluid flow direction, the depth is 0.8mm, the width is 400μm, and the length is 4cm; The material layer 2 has a large number of micropores 5 penetrating through it.

Embodiment 3

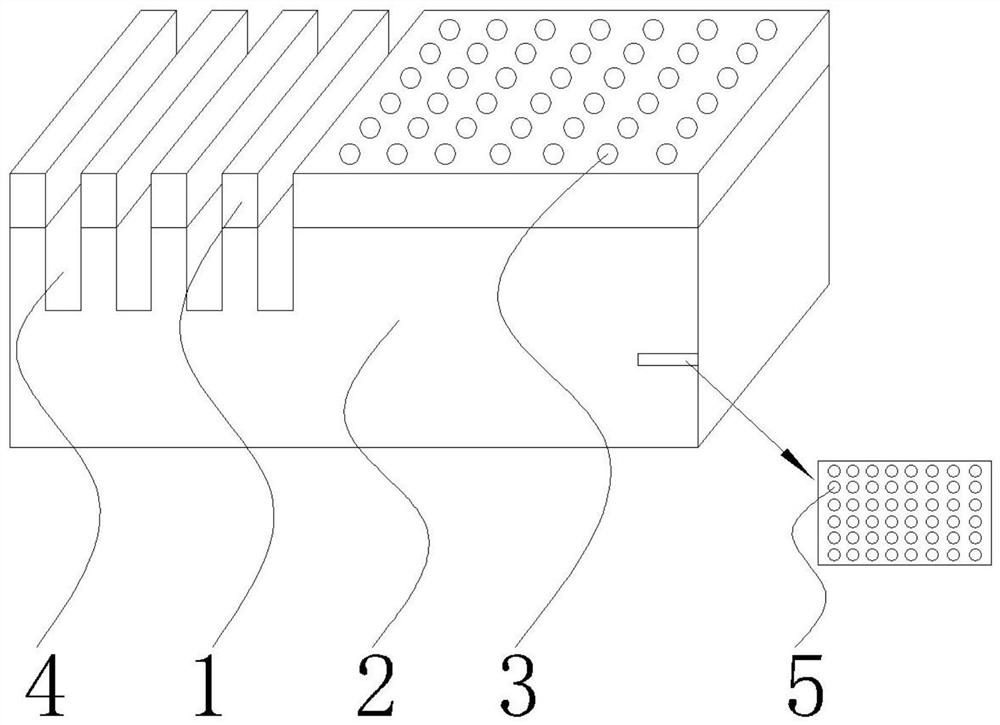

[0032] Such as image 3 As shown, a flow transition passive control device using surface openings / grooves in this embodiment includes an upper layer of metal material layer 1 and a lower layer of sound-absorbing material layer 2, the thickness of the metal material layer 1 is 1mm, and the sound-absorbing material layer The thickness of layer 2 is 2 mm; the surface of the flow transition passive control device is provided with micropores 3 and microgrooves 4 regularly distributed on the surface, and the micropores 3 and microgrooves 4 penetrate the metal material layer 1 and extend to the sound-absorbing material layer 2; Among them, the micropore 3 is a structure with an open top and a closed bottom, with a circular cross section, a depth of 2.5 mm, and a diameter of 300 μm; the microgroove 4 is a structure with an open top and a closed bottom, with a rectangular cross section and a length of 4 The direction is perpendicular to the direction of fluid flow, the depth is 2.5mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com