Automatic loading system for emulsified ammonium nitrate fuel oil explosives

An ammonium-fueled explosive, automatic technology, applied in the directions of loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of limited use scenarios, high labor intensity, low efficiency, etc., and achieve low maintenance costs in the later period. The effect of high land area and loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

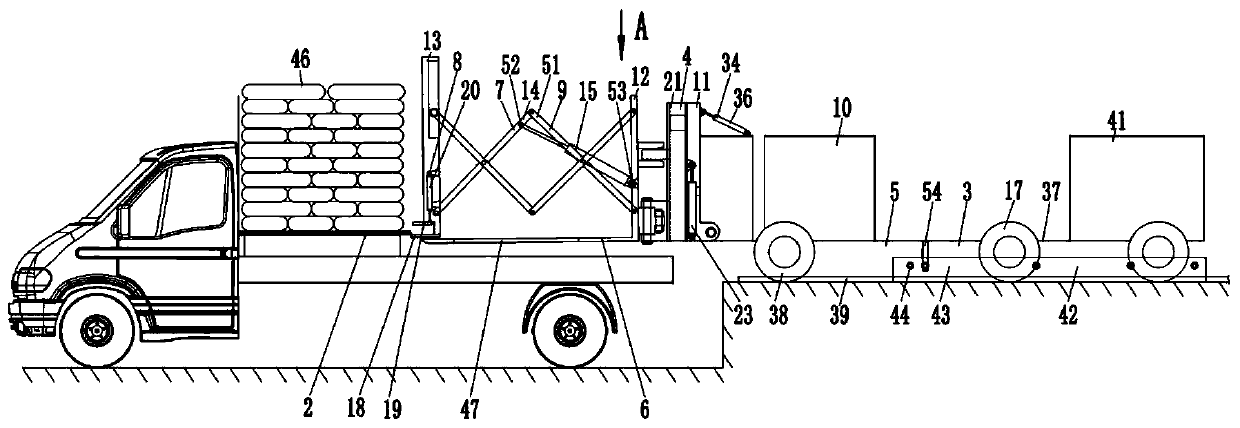

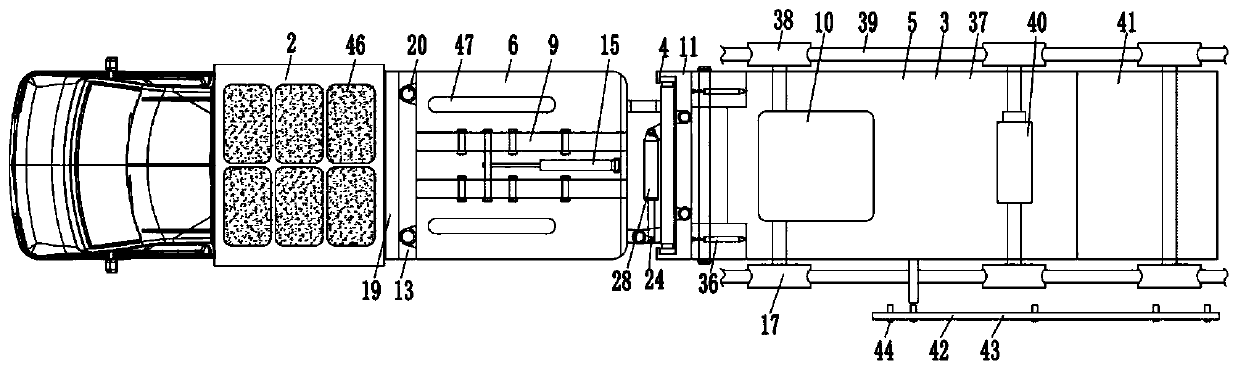

Embodiment 1

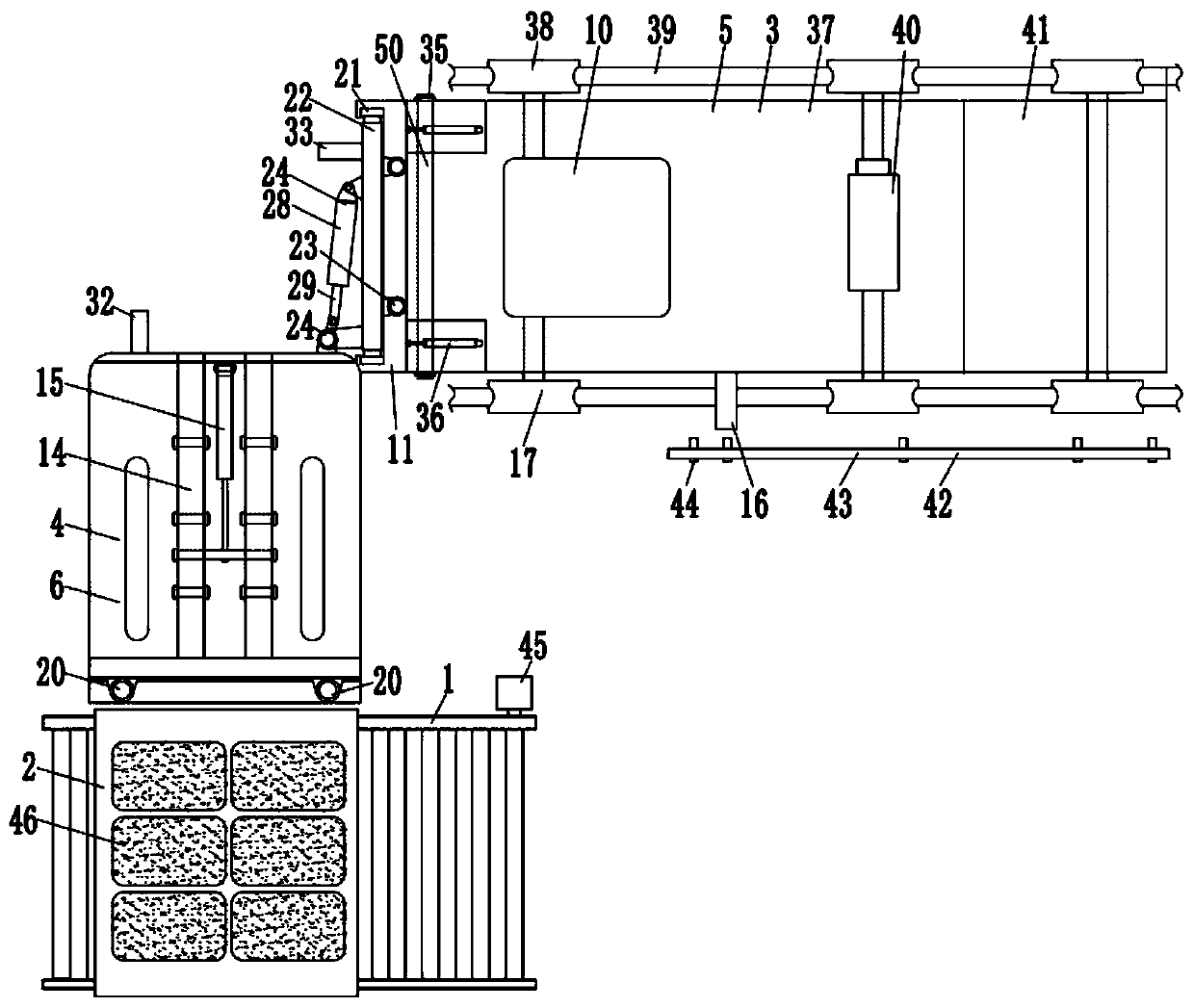

[0027] An automatic loading system for emulsified ammonium oil explosives of the present invention comprises a stacking conveyor and a pallet arranged on the stacking conveyor, a hydraulic loading system is provided on one side of the stacking conveyor, and the hydraulic loading The system includes a palletizing device and a mobile platform. The palletizing device is connected to one end of the mobile platform. The palletizing device is provided with a consignment plate and a telescopic pressing mechanism that can pull the pallet on the side of the consignment plate. The telescopic compression mechanism includes a compression mechanism for pressing the pallet, and a telescopic mechanism for pulling the pallet to the consignment board. The telescopic compression mechanism is arranged on the palletizing device. The mobile platforms are all connected to the controller.

[0028] The unstacking conveyor is provided with a driving unstacking conveyor driver for driving the unstackin...

Embodiment 2

[0033] The difference between this embodiment and embodiment 1 is:

[0034] The stacking device is also provided with a lifting mechanism, the lifting mechanism includes a lifting guide rail that is movably installed with the connecting seat, a lifting driver that drives the lifting guide rail to move up and down in the connecting seat, and the lifting guide rail is connected to the first vertical plate , the lifting driver is connected with the controller.

[0035] After the stacking is completed, the explosives stack is lowered to a suitable position by the lifting mechanism, which can lower the center of gravity of the explosives stack during the transfer process, and it is not easy to shake the explosives stack, collapse or slide the stack, and the packed explosives stack is neat and saves energy. The loading space of each explosive stack, the space utilization rate of the compartment or the vehicle board is high, and it is convenient for the later unloading process.

[0...

Embodiment 3

[0038] Such as Figure 1-4 As shown, a kind of emulsified ammonium oil explosives automatic loading system of the present invention comprises a stacking conveyor, a pallet arranged on the stacking conveyor, a hydraulic loading system is provided on one side of the stacking conveyor, and the The hydraulic loading system includes a palletizing device and a mobile platform. The palletizing device is connected to one end of the mobile platform. The palletizing device is equipped with a consignment plate and a telescopic and compacting mechanism on the side of the consignment plate that can pull the pallet. , the consignment board is provided with an avoidance groove, and sundries on the consignment board can fall from the avoidance groove to avoid interference with stacking and unstacking. The telescopic compression mechanism includes a compression mechanism for compressing the pallet, a The board is pulled to the telescopic mechanism of the consignment board. The telescopic press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com