Selenium-rich ceramic material and preparation method thereof

A ceramic material and selenium-enriched technology, which is applied in the field of ceramic materials, can solve the problems of difficult quantitative control of intake, detection and measurement of selenium release, and high selenium-enriched content of selenium-enriched materials, and achieves the effects of simple process and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

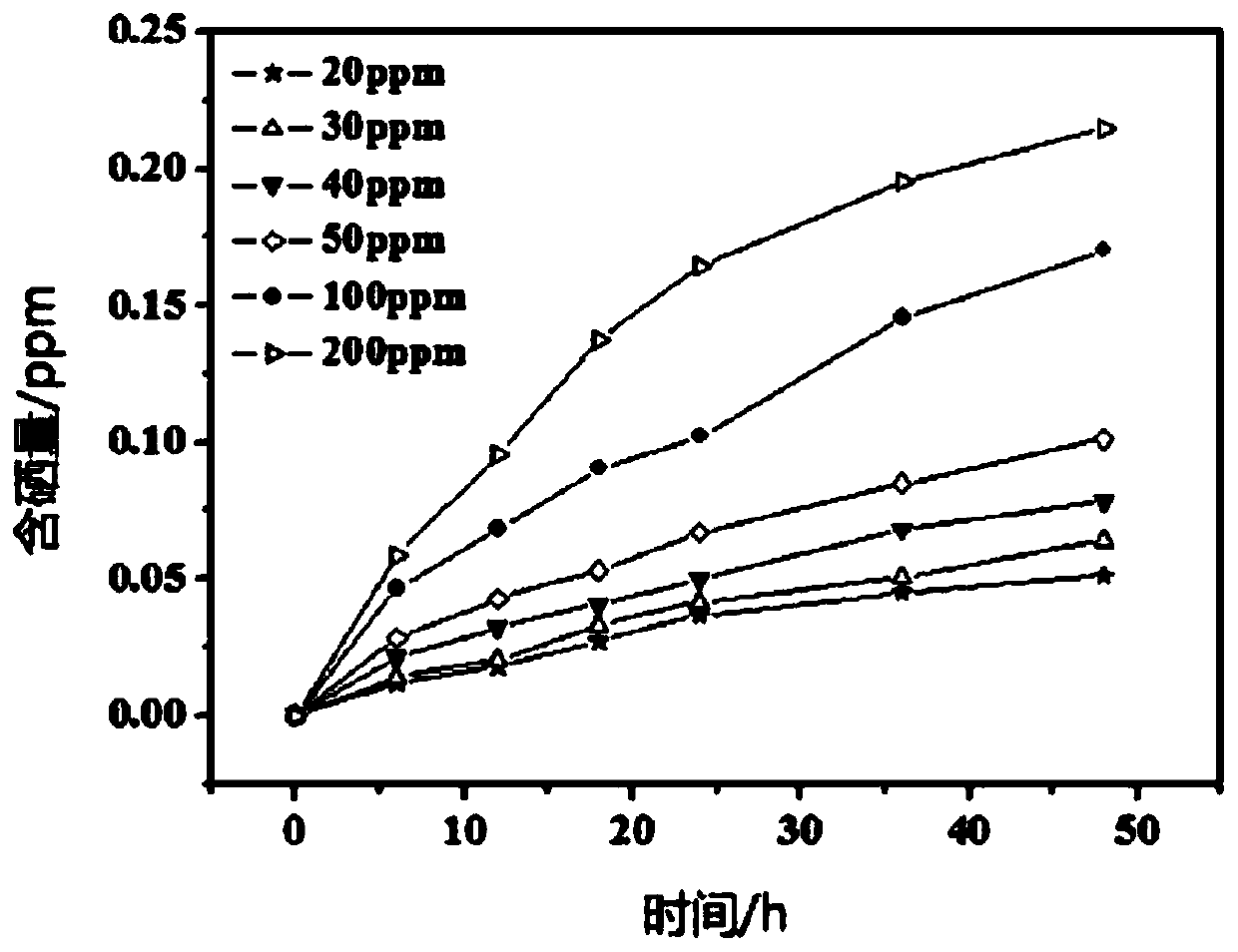

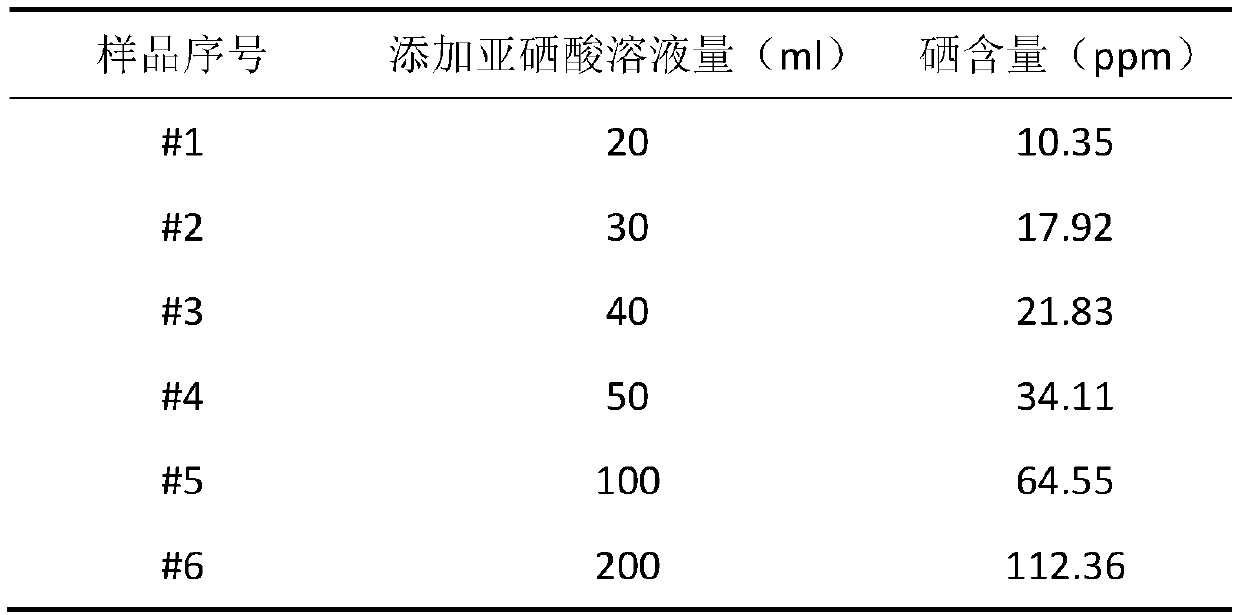

[0030] In this example, in order to clearly illustrate that the selenium content of selenium-rich ceramic materials and the amount of selenium dissolved in water can be controlled by this preparation method, we prepare multiple samples and compare them by adding selenous acid solutions of different capacities .

[0031] Step 1: Weigh 100mg of selenium powder and put it in a beaker, then add a mixed acid of nitric acid and hydrochloric acid to dissolve and react the selenium powder. After the dissolution is completed, the solution is acid-displaced and fixed to a 1000ml volumetric flask to obtain 100ppm selenous acid solution.

[0032] Step 2: Weigh 6 parts of clay dry powder of 10g each, add 20ml, 30ml, 40ml, 50ml, 100ml and 200ml of selenous acid solution respectively, add appropriate amount of water for ball milling and drying, and obtain selenium-enriched soil powder material Samples, denoted as #1, #2, #3, #4, #5 and #6.

[0033] The third step: making 6 parts of seleniu...

Embodiment 2

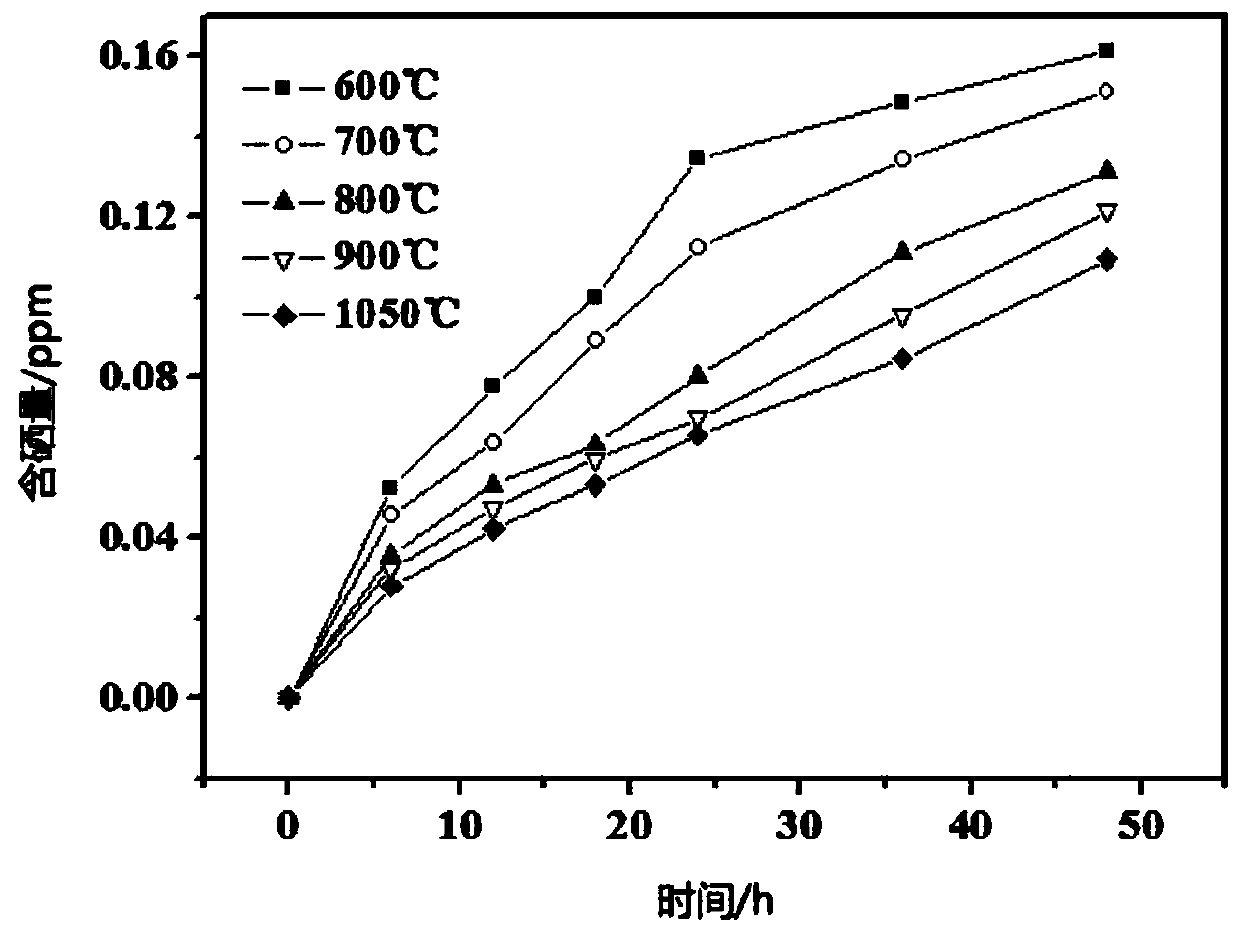

[0041] In this example, in order to clearly illustrate that this preparation method can be used to control the selenium content of selenium-rich ceramic materials and the amount of selenium dissolved in water after immersion, we prepared multiple samples, and compared them by taking different sintering temperatures. Se content and elution in selenium ceramic samples.

[0042] Step 1: Make a soluble selenous acid solution; weigh 100mg of selenium powder and place it in a beaker, then add a mixed acid of nitric acid and hydrochloric acid to dissolve and react the selenium powder. In the volumetric flask, obtain the selenous acid solution of 100ppm.

[0043] The second step: take 5 parts of pottery clay dry powder of 10g each, add 40ml of selenous acid solution, add appropriate amount of water for ball milling and drying, and obtain selenium-enriched pottery clay powder material samples, which are recorded as #7, #8, #9, #10 and #11.

[0044] Step 3: 5 parts of selenium-enriche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com