Surface coating slurry and coating method thereof

A coating method and surface coating technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the incomplete feedback of ceramic coating uniformity, inaccurate measurement, and small coating amount and other problems, to improve the overall stability and adhesion, save test time, and avoid oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

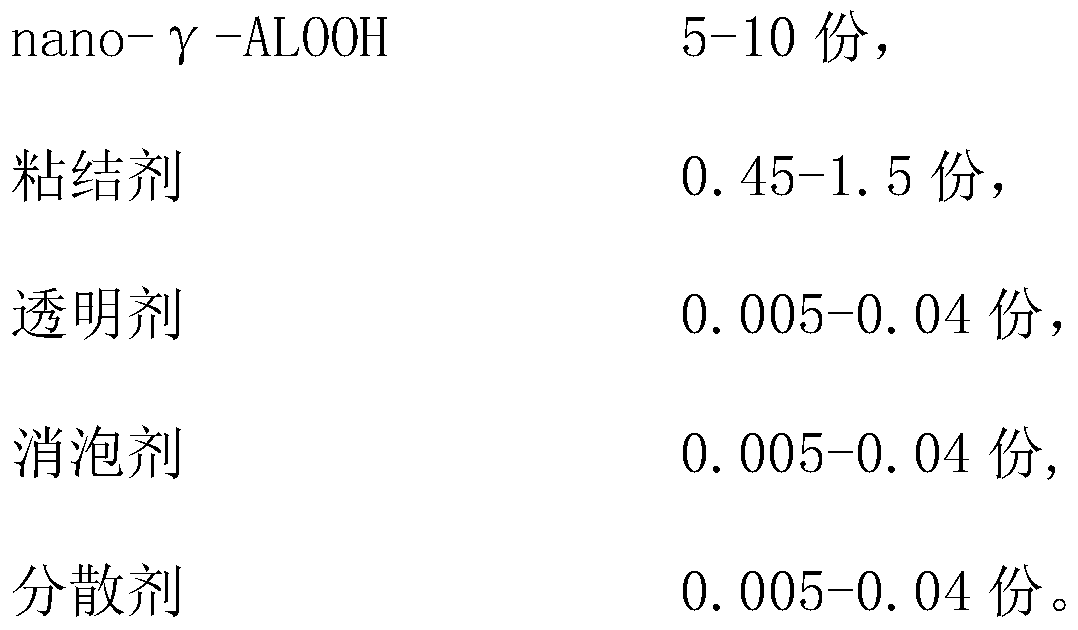

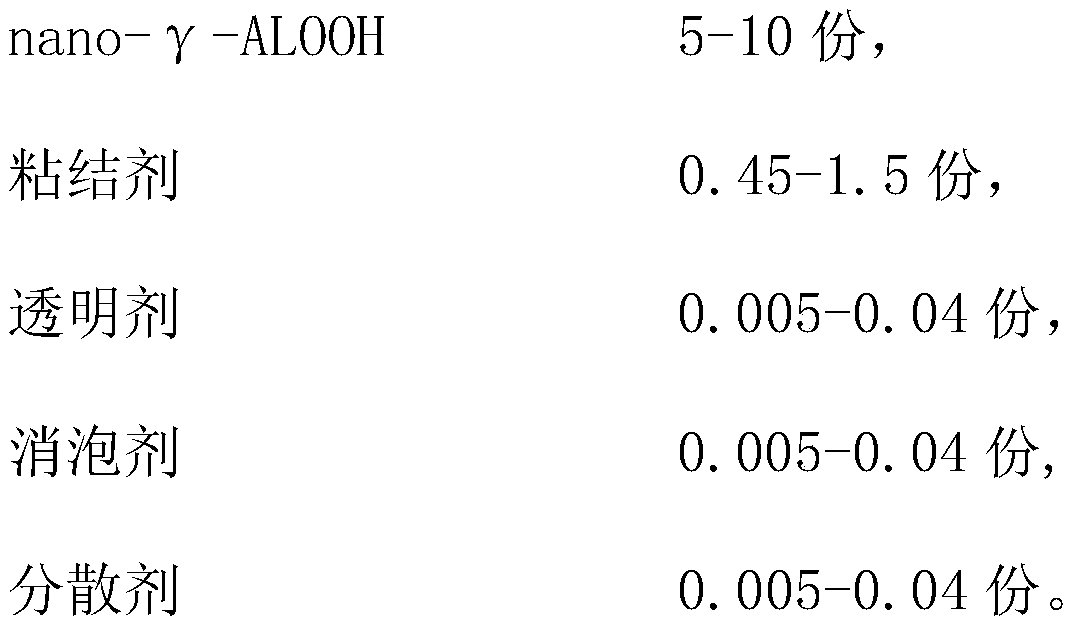

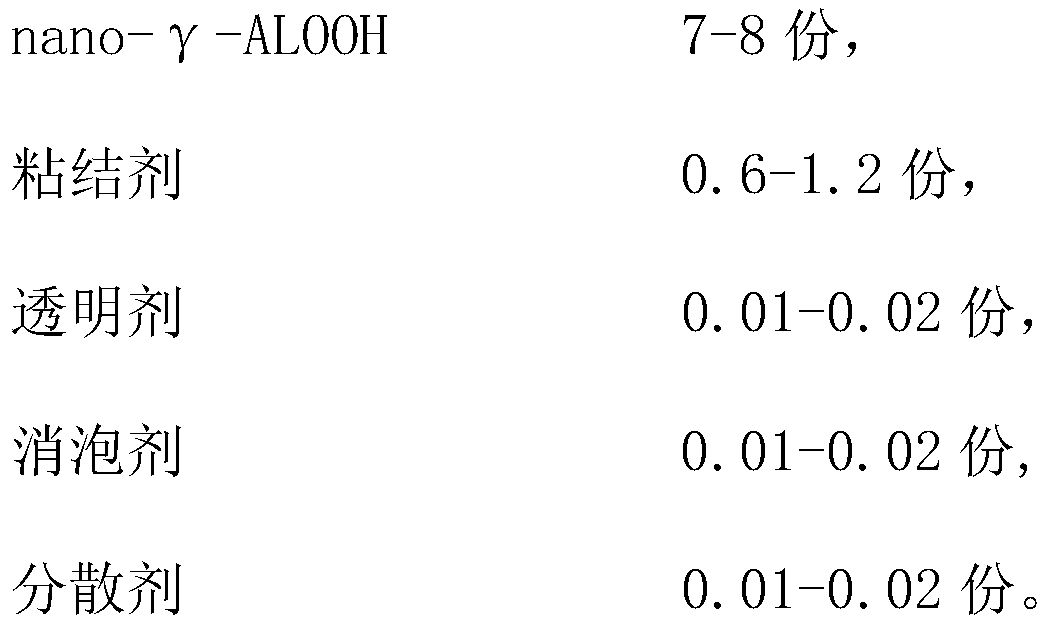

[0029] A surface coating slurry, the surface coating slurry is made of raw materials including the following parts by weight: 7 parts of nano-γ-ALOOH, 0.3 parts of dibutyl phthalate, 0.6 parts of PVDF, 0.015 parts of TM-6 , 0.015 parts of polyether, 0.015 parts of polyacrylamide.

[0030] The coating method of described surface coating slurry, comprises the steps:

[0031] (1) Dissolve the binder uniformly in the solvent NMP, add nano-γ-ALOOH, transparent agent, defoamer and dispersant to it, stir and mix to form a slurry, the solid content of the slurry is 23%, Viscosity 100cp;

[0032] (2) Coat the slurry evenly on the pole piece at a coating speed of 150m / min, and conduct low-temperature vacuum heating with a vacuum degree of ≤-0.090MPa and a temperature of 50°C so that all the air bubbles in the slurry are discharged and leveled evenly. Then carry out vacuum infrared heating, and quickly dry NMP in an oxygen-deficient state to avoid color development of the slurry and ox...

Embodiment 2

[0035] A surface coating slurry, the surface coating slurry is made of raw materials including the following parts by weight: 10 parts of nano-γ-ALOOH, 0.5 parts of dibutyl phthalate, 1.0 parts of PVDF, 0.03 parts of TM-6, 0.02 parts of polyether, 0.02 parts of polyacrylamide.

[0036] The coating method of described surface coating slurry, comprises the steps:

[0037] (1) Dissolve the binder uniformly in the solvent NMP, add nano-γ-ALOOH, transparent agent, defoamer and dispersant to it, stir and mix to form a slurry, the solid content of the slurry is 25%, Viscosity 150cp;

[0038] (2) Coat the slurry evenly on the pole piece at a coating speed of 100m / min, heat in vacuum at low temperature, the vacuum degree is ≤-0.090MPa, and the temperature is 55°C, so that all the air bubbles in the slurry are discharged and evenly leveled, Then vacuum infrared heating is carried out, and the NMP is quickly dried in an oxygen-deficient state to avoid color development of the slurry an...

Embodiment 3

[0041] A surface coating slurry, the surface coating slurry is made of raw materials including the following parts by weight: 5 parts of nano-γ-ALOOH, 0.15 parts of dibutyl phthalate, 0.4 parts of PVDF, 0.03 parts of TM-6, 0.03 parts of polyether, 0.02 parts of polyacrylamide.

[0042] The coating method of described surface coating slurry, comprises the steps:

[0043] (1) Dissolve the binder uniformly in the solvent NMP, add nano-γ-ALOOH, transparent agent, defoamer and dispersant to it, stir and mix to form a slurry, the solid content of the slurry is 20%, Viscosity 100cp;

[0044] (2) Coat the slurry evenly on the pole piece at a coating speed of 200m / min, heat in vacuum at low temperature, the vacuum degree ≤ -0.090MPa, and the temperature is 60°C, so that all the air bubbles in the slurry are discharged and evenly leveled, Then vacuum infrared heating is carried out, and the NMP is quickly dried in an oxygen-deficient state to avoid the color development of the slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com