An environmentally friendly mixed working fluid

A mixed working medium and environmental protection technology, applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of insufficient low-temperature heating, high global warming potential, etc., to achieve volumetric cooling capacity and volumetric heating capacity increase, environmental protection The effect of superior performance and superior physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

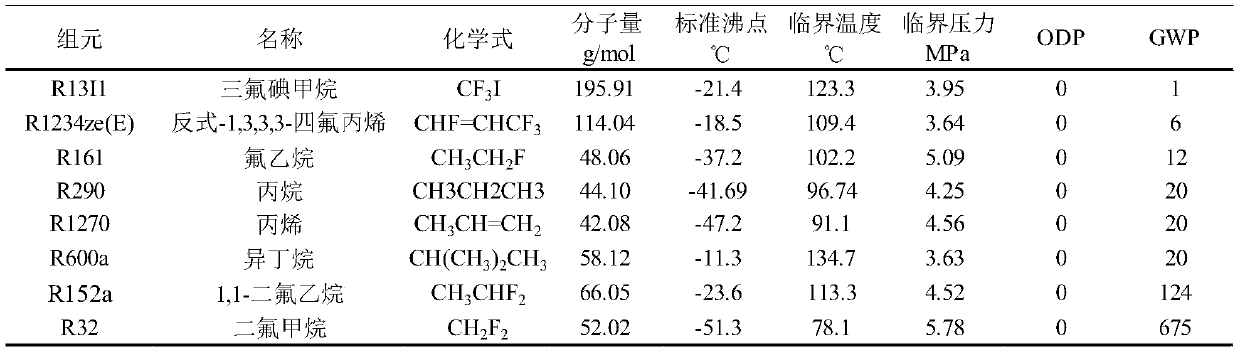

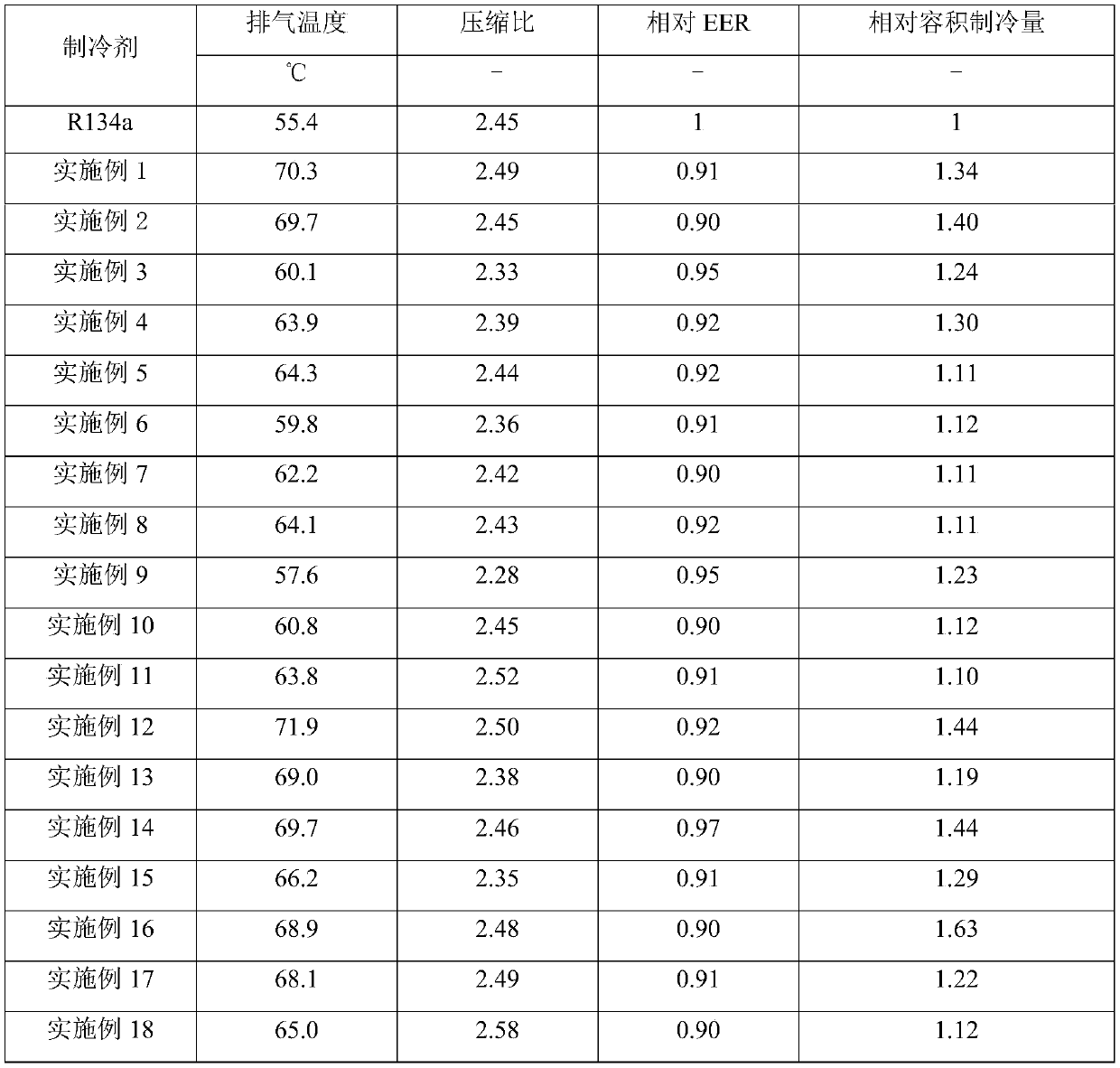

Method used

Image

Examples

Embodiment 1

[0031] Example 1: four groups of trifluoroiodomethane (R13I1), fluoroethane (R161), difluoromethane (R32) and trans-1,3,3,3-tetrafluoropropene (R1234ze(E)) At a temperature of 23-27°C, liquid-phase mixing is carried out according to the mass percentage of 49:40:5:6 and stirred for 1-2 hours as a refrigerant.

Embodiment 2

[0032] Example 2: The four components of trifluoroiodomethane (R13I1), propylene (R1270), fluoroethane (R161) and difluoromethane (R32) were mixed at a temperature of 23-27°C in a ratio of 51:9:37:3 The mass percentage is mixed in liquid phase and stirred for 1 to 2 hours as a refrigerant.

Embodiment 3

[0033] Example 3: The four components of trifluoroiodomethane (R13I1), 1,1-difluoroethane (R152a), propane (R290) and isobutane were mixed at a temperature of 23 to 27°C at a ratio of 33:34:30 : 3% by mass for liquid phase mixing and stirring for 1 to 2 hours as a refrigerant.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap