Stroke and compression ratio changing mechanism and control method thereof

A control method and compression ratio technology, applied in engine control, mechanical equipment, machine/engine, etc., can solve the problems of engine thermal efficiency decline, long piston work time, short piston work time, etc., to improve thermal efficiency, ensure long work time, The effect of improving running performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0047] The present invention will be described in detail below with reference to the accompanying drawings and examples.

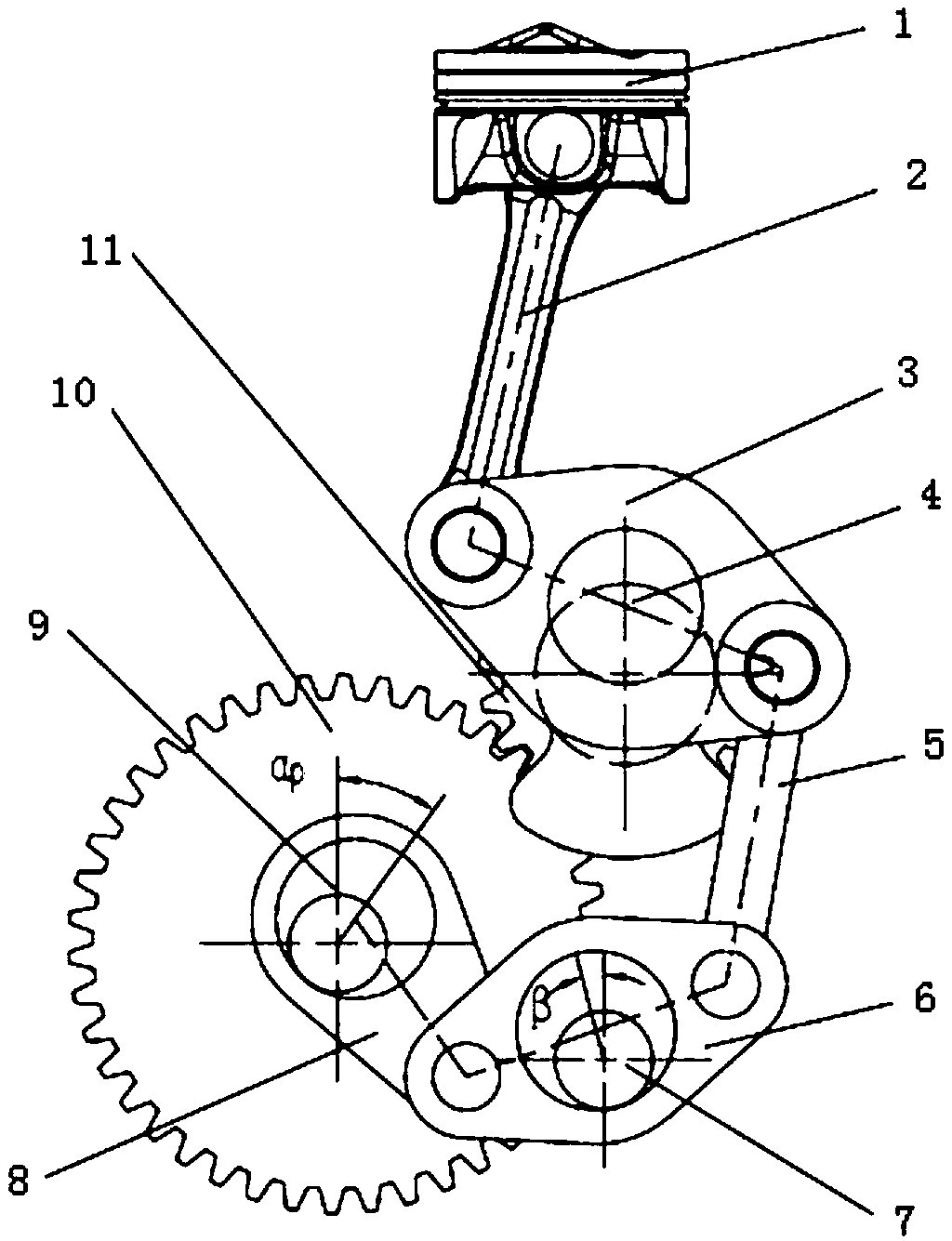

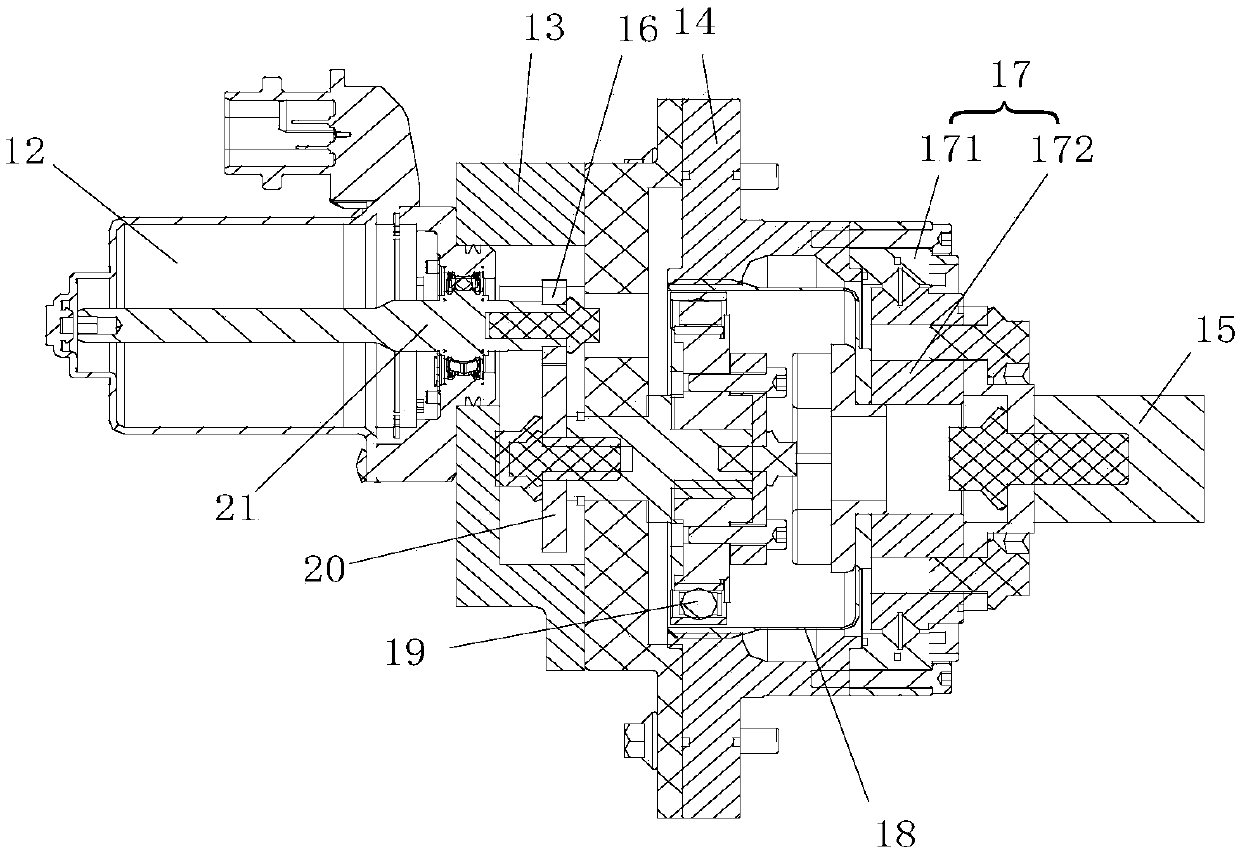

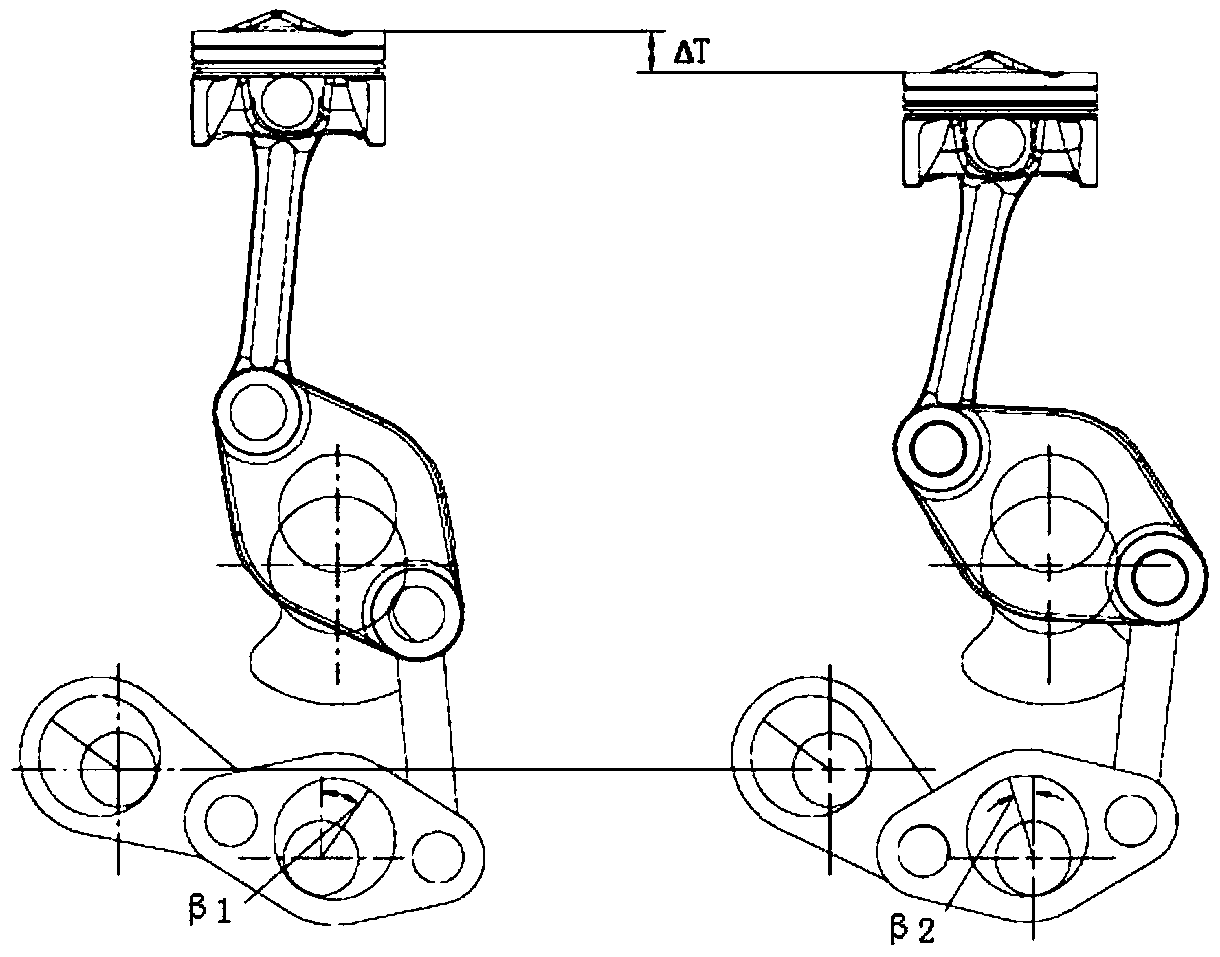

[0048]This embodiment relates to a variable compression ratio mechanism with variable stroke. The variable compression ratio mechanism with variable stroke is controlled by the engine control unit so as to be able to adjust the engine piston stroke and compression ratio, and as figure 1 As shown in , its overall structure includes a piston 1, a crankshaft 4, an eccentric shaft 7, a control shaft 9, and a connecting rod 2, an adjusting connecting rod 3, a driving connecting rod 5 and a swing connecting rod arranged between the above-mentioned components. The multi-link structure formed by the rod 6 and the follower link 8.

[0049] Specifically, the piston 1 is slidably arranged in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com