Megawatt level low speed direct-driven wind turbine generator shaft system device

A wind power generator, megawatt-level technology, applied in the field of megawatt-level low-speed direct-drive wind power generator shafting device, can solve the problems that the deformation of the air gap cannot be effectively suppressed, and the overall performance of the generator and the generator set cannot be effectively improved. Achieve the effect of small deformation, increase rigidity and reduce overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

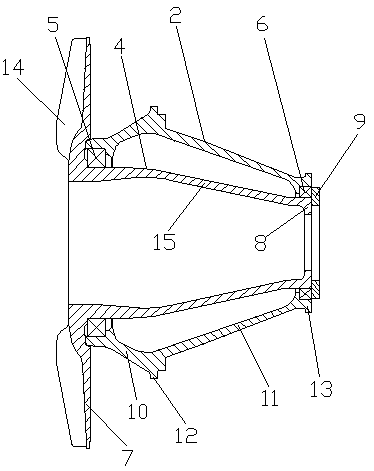

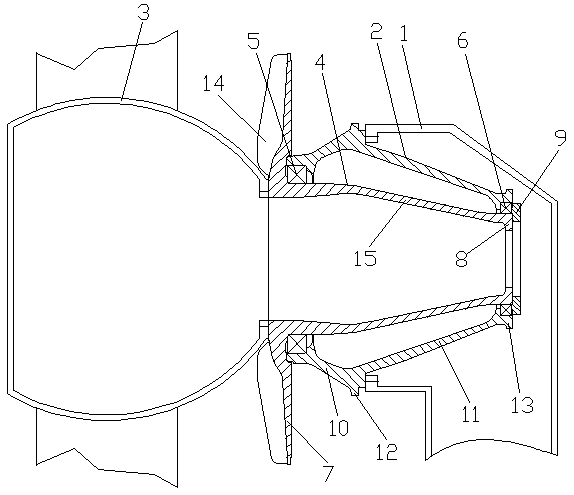

[0034] see figure 1 and figure 2, a megawatt-level low-speed direct-drive wind turbine shafting device, including a fixed shaft 2 coupled to the fixed end of the main frame 1 and a rotating shaft 4 coupled to the hub 3, the rotating shaft 4 is located inside the fixed shaft 2 An upwind bearing 5 and a downwind bearing 6 for supporting the rotation of the rotating shaft 4 are arranged between the fixed shaft 2 and the rotating shaft 4, the upwind bearing 5 is located on the hub 3 side, and the downwind bearing 6 is located on the main frame 1- On the side, the cross sections of the fixed shaft 2 and the rotating shaft 4 are tapered, and the section bending strength on the tapered surface 15 of the rotating shaft is equal. One end of the rotating shaft 4 is provided with a large flange 7, and the other end of the rotating shaft 4 is provided with There is a rotating shaft reinforced flange 8, the large flange 7 is located on the side of the upwind bearing 5, the rotating shaft...

Embodiment 2

[0037] see figure 1 and figure 2 , a megawatt-level low-speed direct-drive wind turbine shafting device, including a fixed shaft 2 coupled to the fixed end of the main frame 1 and a rotating shaft 4 coupled to the hub 3, the rotating shaft 4 is located inside the fixed shaft 2 An upwind bearing 5 and a downwind bearing 6 for supporting the rotation of the rotating shaft 4 are arranged between the fixed shaft 2 and the rotating shaft 4, the upwind bearing 5 is located on the hub 3 side, and the downwind bearing 6 is located on the main frame 1- On the side, the cross sections of the fixed shaft 2 and the rotating shaft 4 are tapered, and the section bending strength on the tapered surface 15 of the rotating shaft is equal. One end of the rotating shaft 4 is provided with a large flange 7, and the other end of the rotating shaft 4 is provided with There is a rotating shaft reinforced flange 8, the large flange 7 is located on the side of the upwind bearing 5, the rotating shaf...

Embodiment 3

[0043] see figure 1 and figure 2 , a megawatt-level low-speed direct-drive wind turbine shafting device, including a fixed shaft 2 coupled to the fixed end of the main frame 1 and a rotating shaft 4 coupled to the hub 3, the rotating shaft 4 is located inside the fixed shaft 2 An upwind bearing 5 and a downwind bearing 6 for supporting the rotation of the rotating shaft 4 are arranged between the fixed shaft 2 and the rotating shaft 4, the upwind bearing 5 is located on the hub 3 side, and the downwind bearing 6 is located on the main frame 1- On the side, the cross sections of the fixed shaft 2 and the rotating shaft 4 are tapered, and the section bending strength on the tapered surface 15 of the rotating shaft is equal. One end of the rotating shaft 4 is provided with a large flange 7, and the other end of the rotating shaft 4 is provided with There is a rotating shaft reinforced flange 8, the large flange 7 is located on the side of the upwind bearing 5, the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com