Servo motor dynamic cable

A dynamic cable and servo motor technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems affecting the stability and reliability of the signal transmission signal of the signal line, the damage of the conductive unit of the signal line, that is, the power line, and the structure of the signal line. Unreasonable and other problems, to achieve good anti-rolling, excellent anti-drag wear, and improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

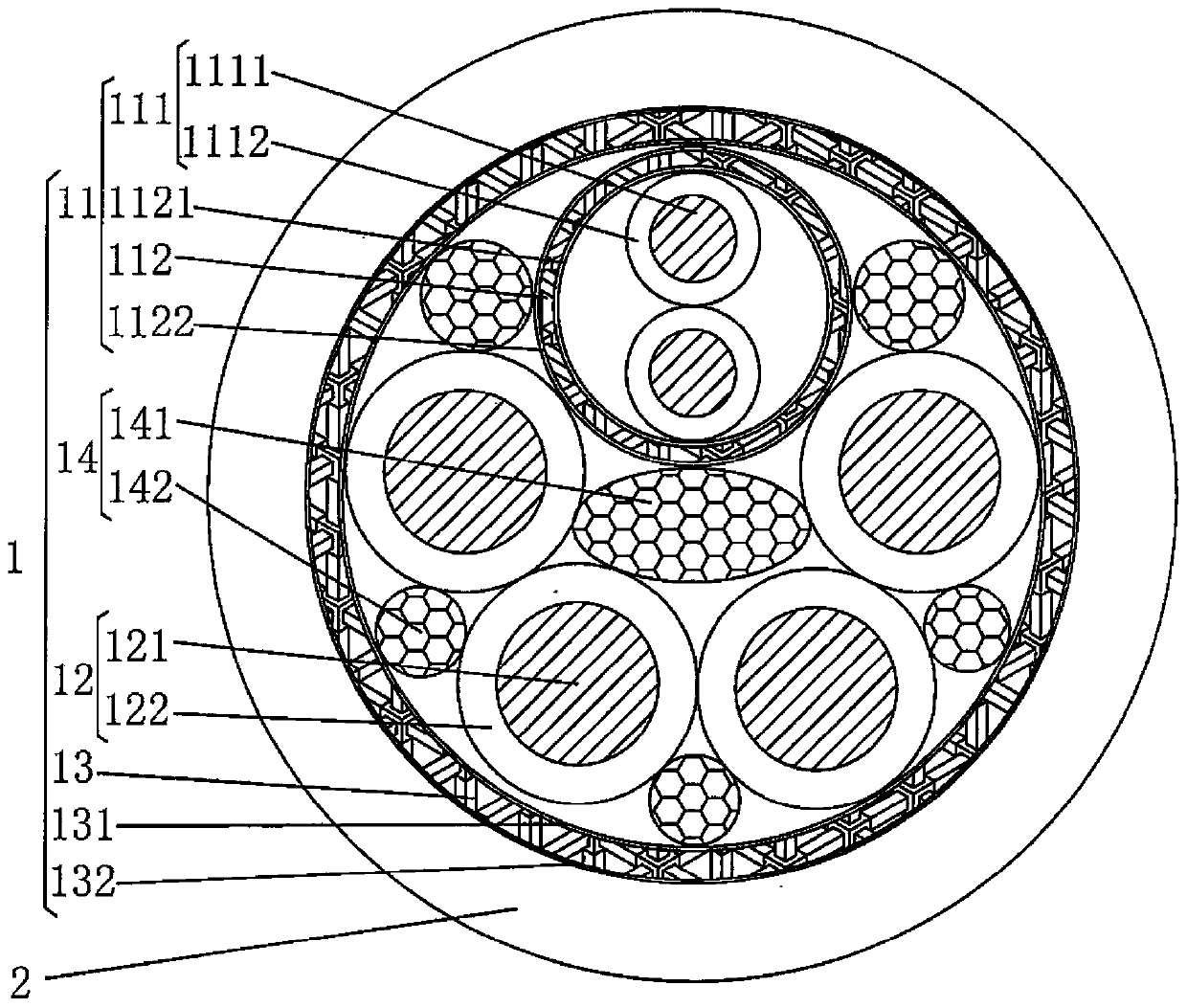

[0024] See figure 1 , showing a cable core 1 and an outer sheath 2 extruded outside the cable core 1, the aforementioned cable core 1 includes a signal line unit 11, a conductive unit 12 and a cable core shielding layer 13, and the cable core shielding layer 13 envelopes Outside the signal line unit 11 and the conductive unit 12, that is, the cable core shielding layer 13 is located outside the signal line unit 11 and the conductive unit 12. In this embodiment, there is one signal line unit 11, and the signal line unit 11 includes one For the signal transmission line 111 and an inner shielding sleeve 112 , a pair of signal transmission lines 111 are located inside the inner shielding sleeve 112 , and in this embodiment, there are four conductive units 12 .

[0025] As the technical gist of the technical solution provided by the present invention: the aforementioned pair of signal transmission lines 111 is a 100% untwisted (100% untwisted) twisted pair structure, and the inner ...

Embodiment 2

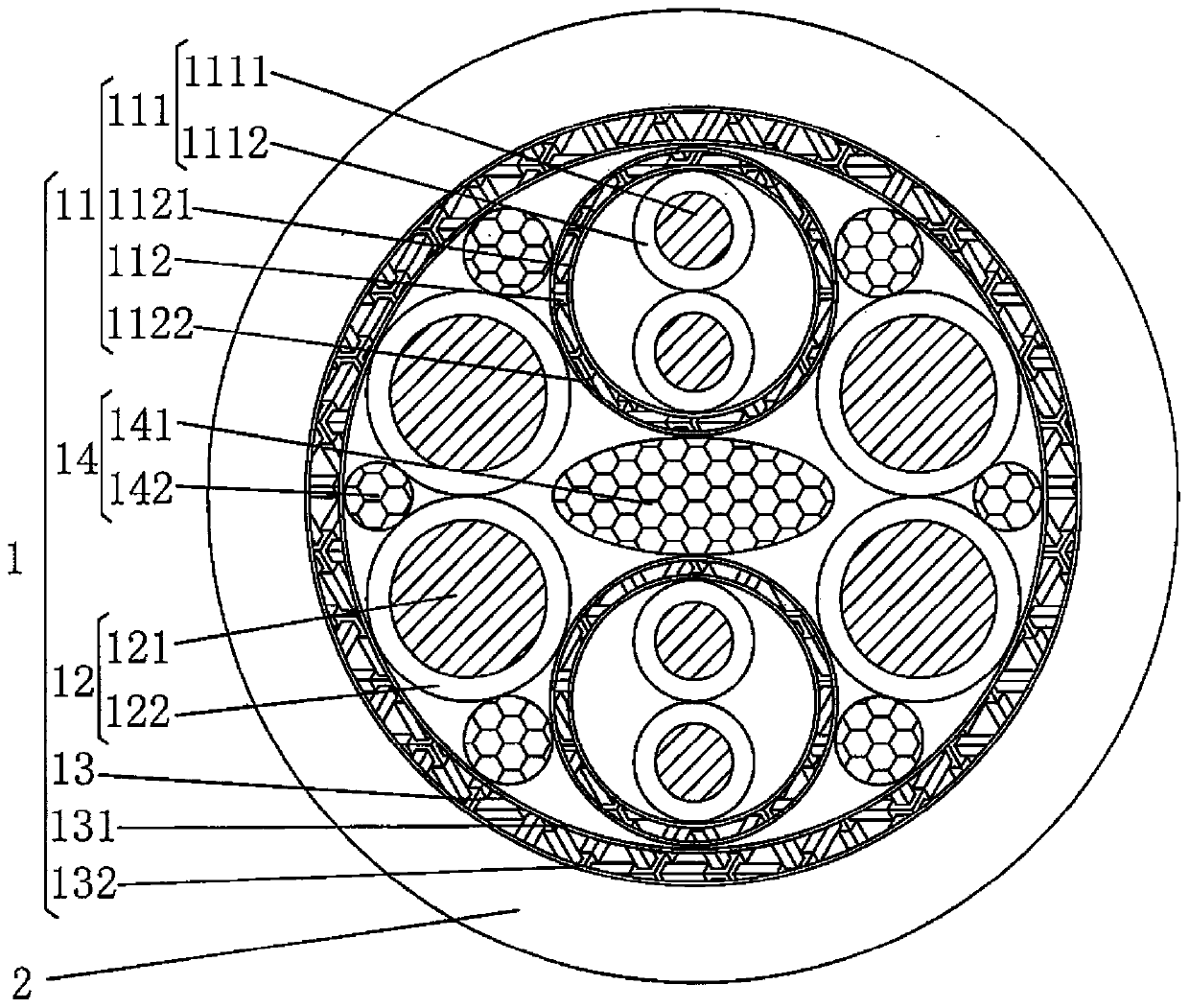

[0035] See figure 2 , compared to Embodiment 1, the number of signal line units 11 is two and they are in a face-to-face state, and there are four conductive units 12 on the left and right respectively. In addition, in this embodiment, the signal transmission line conductor 1111 and the power supply conductor 121 are all twisted with bare soft copper wires. All the other are the same as the description of Example 1.

Embodiment 3

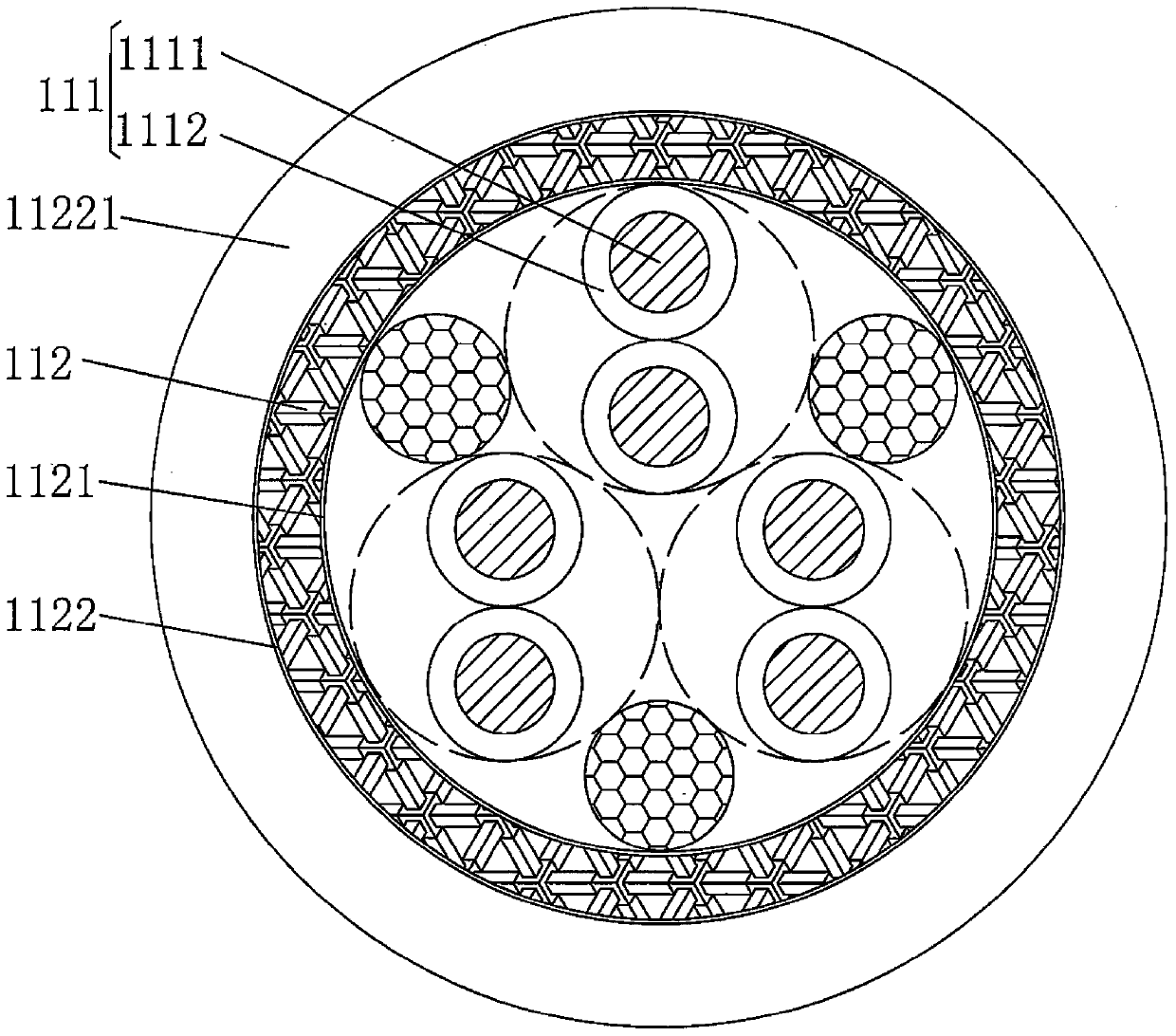

[0037] The third embodiment is essentially another embodiment of the structure of the signal line unit 11 , using three signal line units 11 and extruding a signal line insulating sheath 11221 outside the wrapping layer 1122 of the signal line unit. All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com