Coating film stripping composition and method for stripping coating film

A composition and film coating technology, which is applied in the direction of detergent composition, chemical instrument and method, non-surface active detergent composition, etc., can solve the problems not involving the removal of film film, reduce the removal time and reduce the risk of fire , Viscosity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

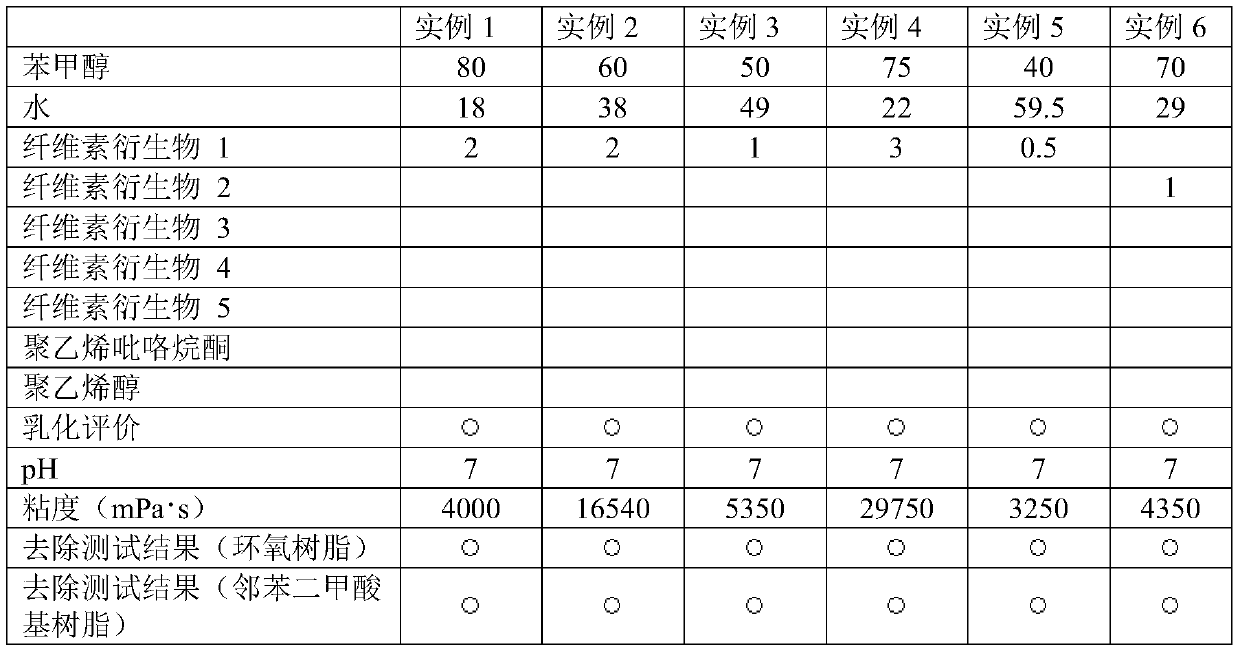

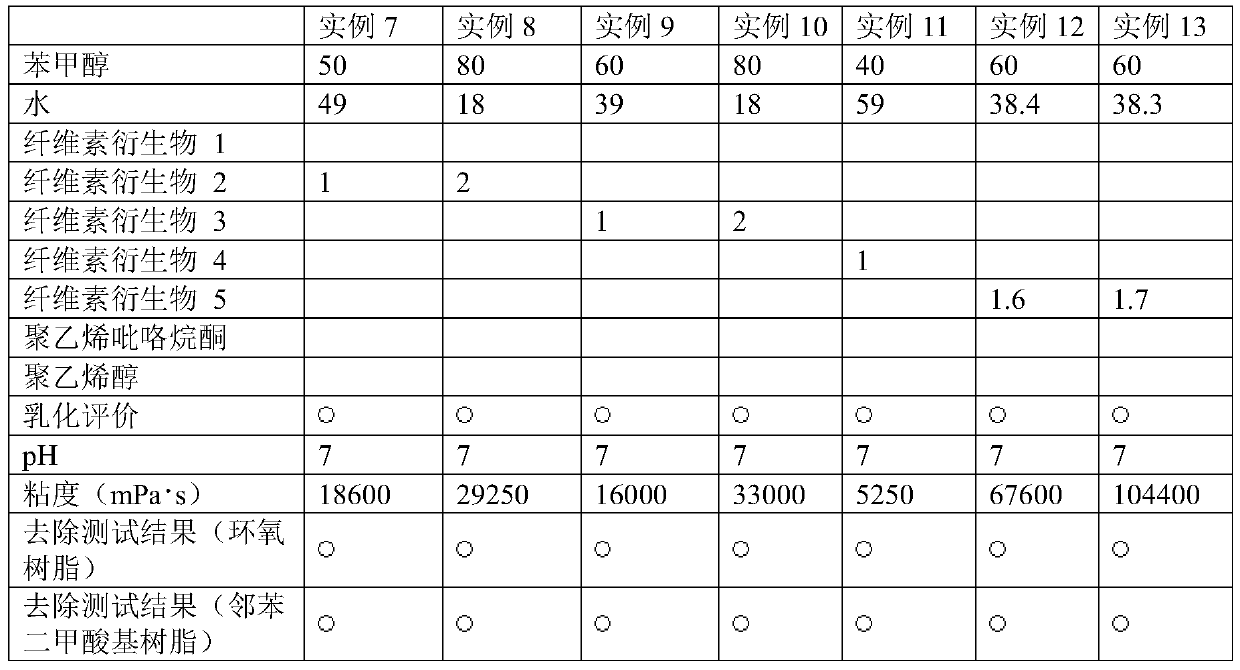

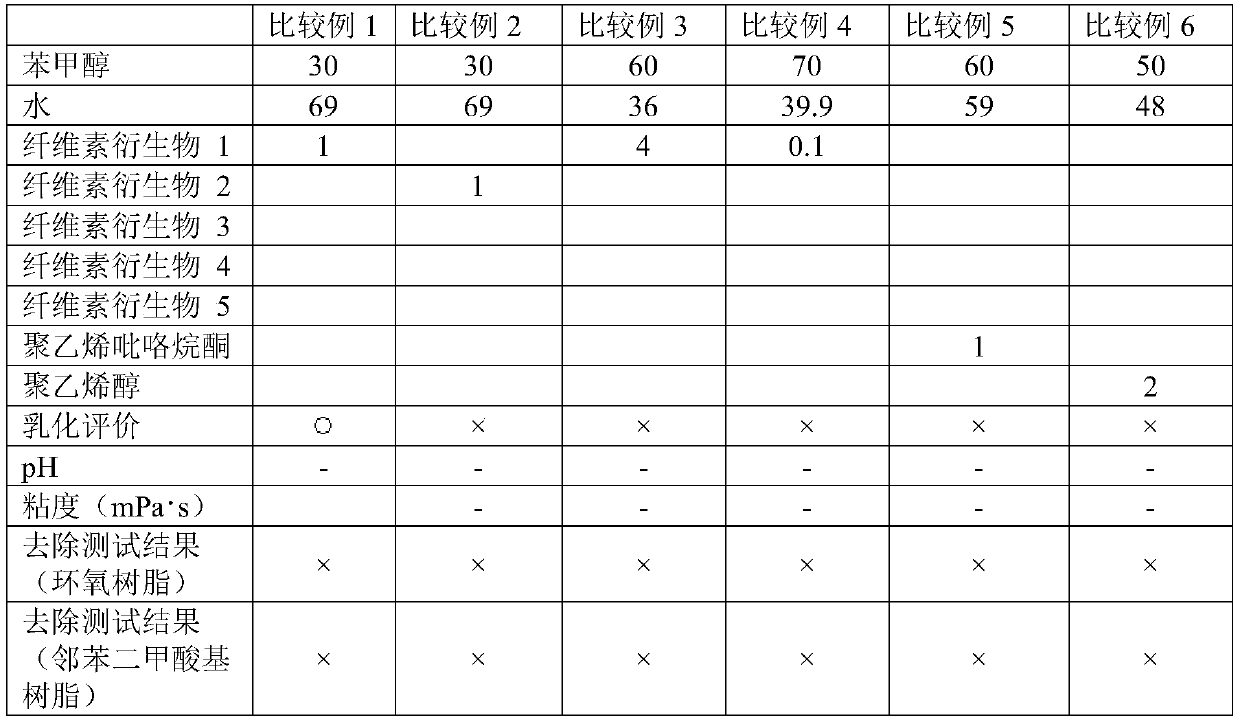

[0036] The present invention is specifically described below with reference to Examples. However, the present invention is not limited to these examples.

[0037] In the following examples and comparative examples, the following cellulose derivatives, polyvinyl alcohol and polyvinylpyrrolidone were used.

[0038] Cellulose Derivatives

[0039] Cellulose derivative 1: Metolose SM-400 produced by Shin-Etsu Chemical Co., Ltd

[0040] Cellulose derivative 2: Metolose 60SH-4000 produced by Shin-Etsu Chemical Co., Ltd.

[0041] Cellulose derivative 3: Metolose 65SH-4000 produced by Shin-Etsu Chemical Co., Ltd.

[0042] Cellulose derivative 4: Metolose 90SH-4000 produced by Shin-Etsu Chemical Co., Ltd.

[0043] Cellulose derivative 5: Metolose SM-4000 produced by Shin-Etsu Chemical Co., Ltd.

[0044] Polyvinylpyrrolidone

[0045] Pitzcol K-90 manufactured by DKS Co.Ltd.

[0046] polyvinyl alcohol

[0047] Kuraray Poval PVA105 produced by Kuraray Co., Ltd.

[0048] ■Examples ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com