Automatic ash discharge briquette drying furnace

An automatic exhaust and drying furnace technology, applied in the field of drying furnace, can solve the problems of low heat utilization rate, blockage, uneven distribution of hot air in the drying furnace, etc., achieve high hot air utilization rate, uniform coal output, and solve the problem of coal output uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

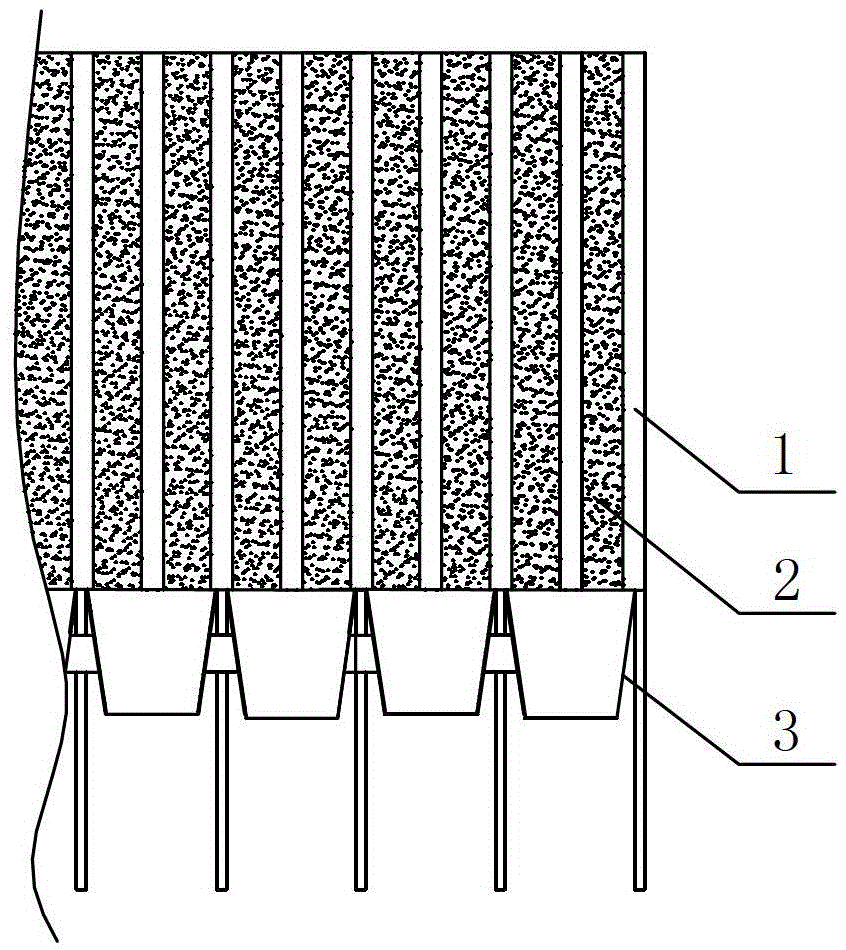

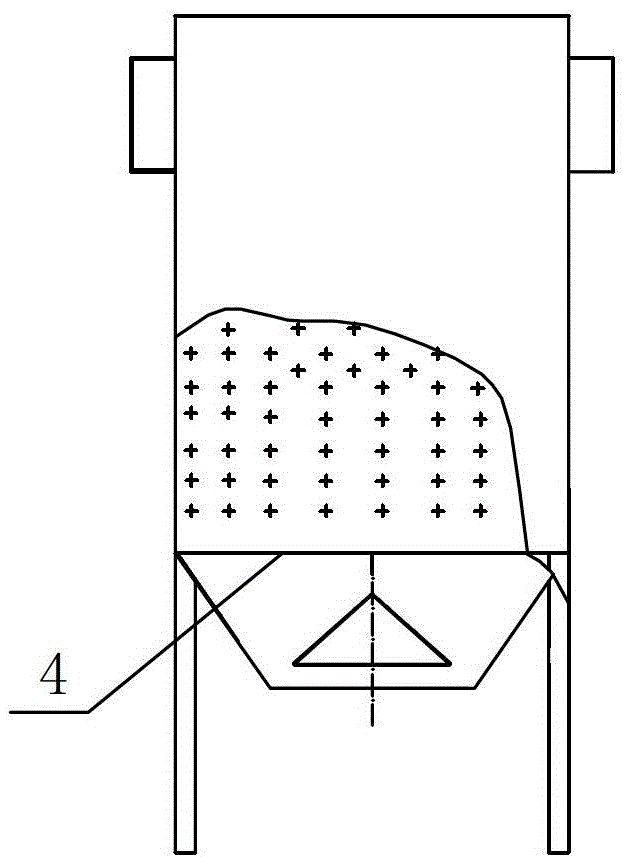

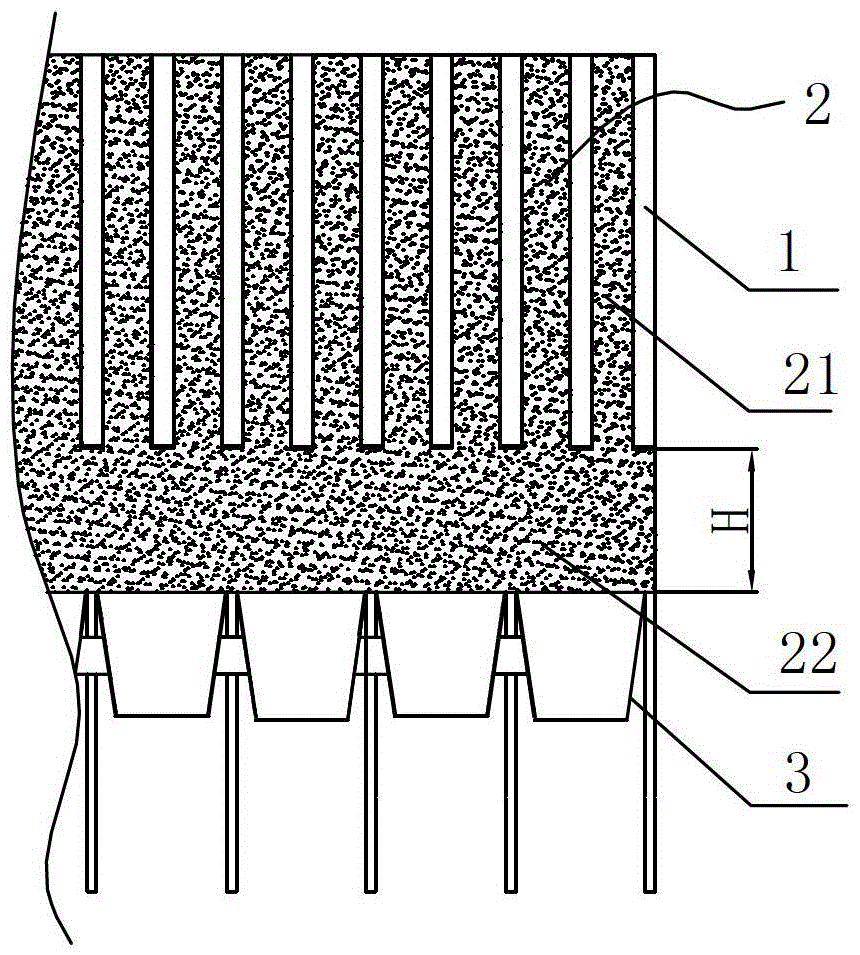

Embodiment 1

[0022] Embodiment 1: a kind of automatic ash-discharging briquette drying furnace, as Figure 3-Figure 4 As shown, it includes a furnace body, a coal hopper 3 positioned at the bottom of the furnace body, and an air channel 1 and a coal channel 2 located in the furnace body. There are several ash discharge holes 5 at the bottom of the air channel, and generally an air channel bottom has a 6 ash discharge holes, the coal passage includes a longitudinal coal passage 21 and a horizontal coal passage 22, the horizontal coal passage is located at the bottom of the furnace body, and the longitudinal coal passage and air passage are arranged at intervals and located above the transverse coal passage , the longitudinal coalway is connected with the horizontal coalway, and the air duct is connected with the horizontal coalway through the ash discharge hole. The height H of the transverse coalway is 1m, and the ash discharge hole is rectangular, and its size is 20×60mm. The coal-slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com