Structure-frp material bond construction and bonding method

A structure and adhesive layer technology, applied in the direction of bonding methods, film/sheet adhesives, adhesives, etc., can solve the problems of increased process time and effort, complicated operation steps, and low adhesive strength

Active Publication Date: 2019-11-22

TORAY IND INC +2

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the reinforcing fiber base is a resin-impregnated prepreg sheet, the adhesive strength can be ensured, but the process time and effort are increased, and depending on the resin, the curing of the resin begins to occur between sealing and vacuum suction. , in addition, air may remain on the bonding surface, resulting in low bond strength

In addition, although the extension parts are of high quality because they are made of prepreg sheets, there is a problem of complicated operation steps due to the need for heat source equipment, etc., due to the construction involving heating.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

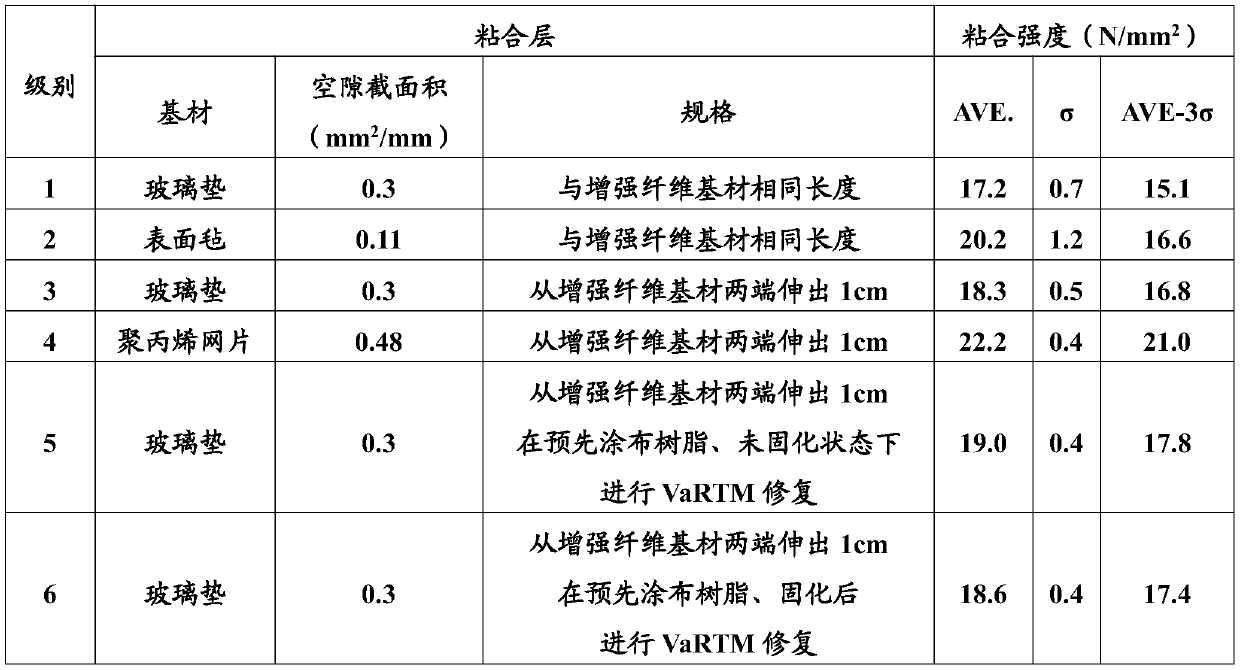

[0049] Hereinafter, in order to confirm the effect of the present invention, the adhesive strength between CFRP and steel material adhered by VaRTM molding was confirmed in the following procedure.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Login to View More

Abstract

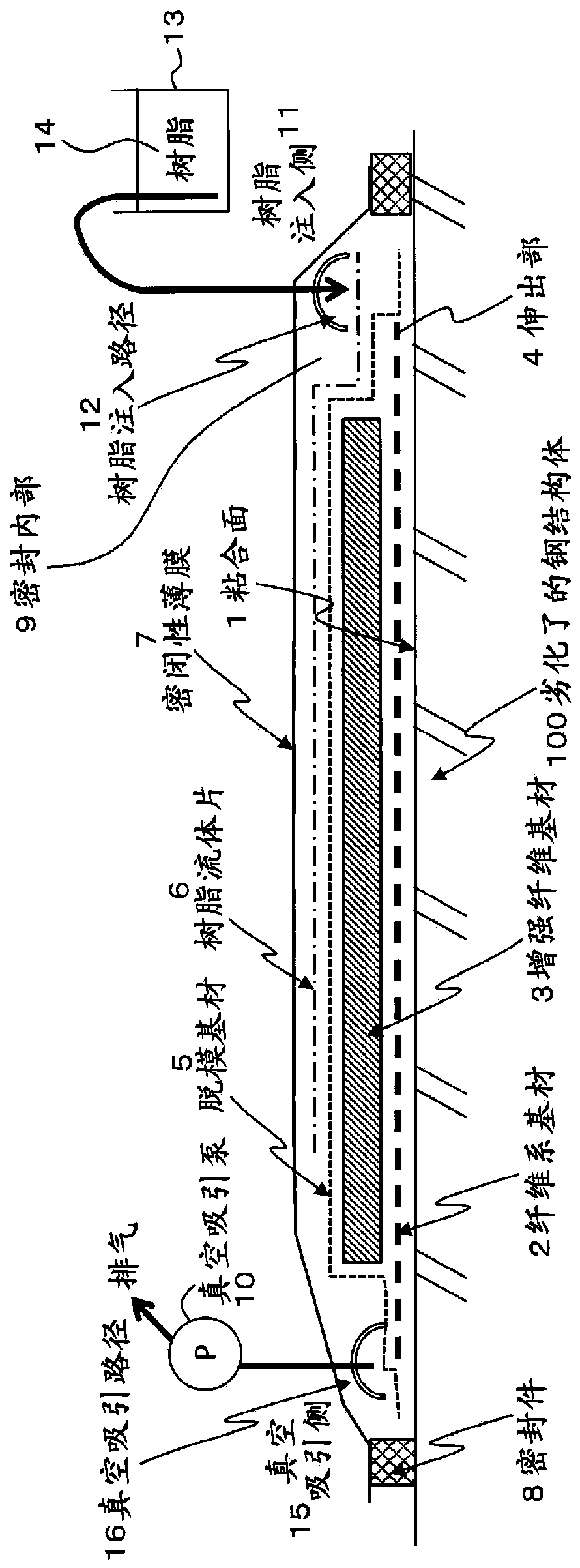

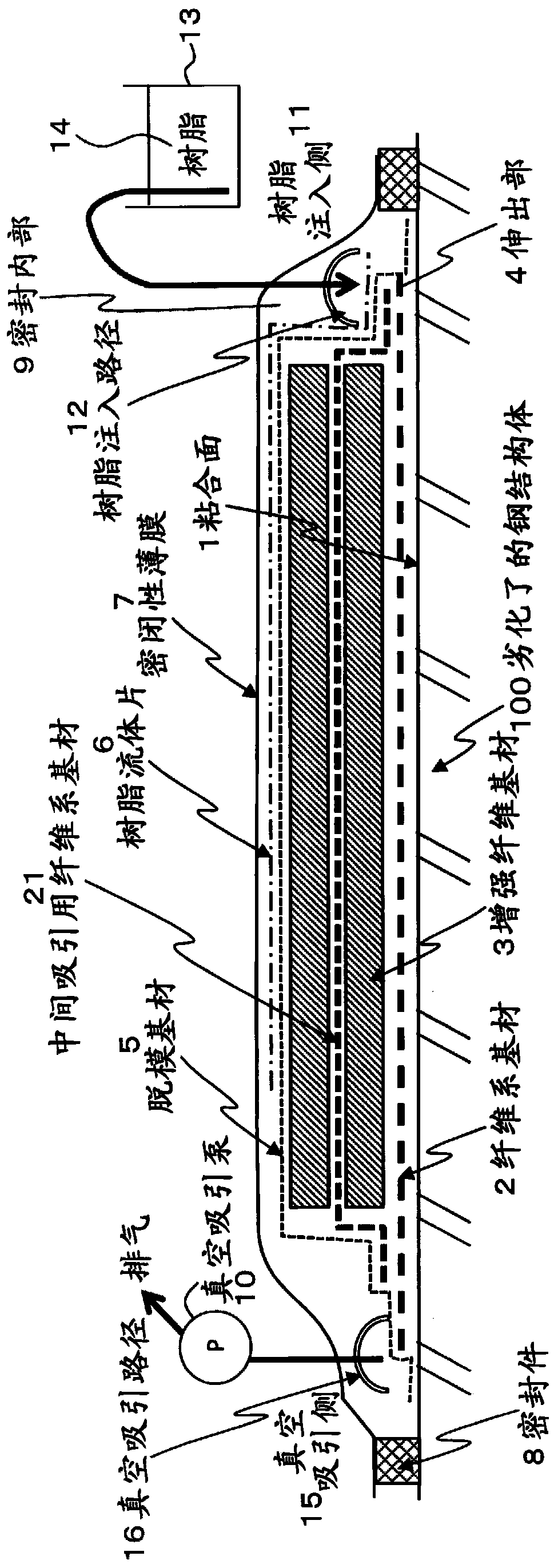

Provided are: a structure-FRP material bond construction, which is a structure for bonding FRP material to structures and is characterized by a bonding layer formed from a resin and a fiber substratebeing interposed between the structure and the FRP material and the bonding layer protruding from the edge of the FRP material; and a bonding method. Repair or reinforcement of an existing structure can be made easily and reliably at a construction site with the required FRP material, and in particular, a sufficiently strong bonding force between the structure and the FRP material for repair or reinforcement can be manifested and an intended repair or reinforcement performance of the FRP material for the structure can be exhibited more reliably.

Description

technical field [0001] The present invention relates to a bonding structure and a bonding method of FRP (fiber reinforced plastic) materials and structures, and particularly relates to an existing structure that needs to be changed in use or an existing structure that has a cross-sectional defect due to corrosion or the like FRP materials and FRP materials that can reliably improve or restore the desired performance of existing structures without bolting or welding, and can easily and reliably use the required FRP materials for repair and reinforcement even at the construction site. The bonding structure and bonding method of the structure. Background technique [0002] In the case of improving the performance of an existing structure (for example, a structure whose surface material is steel or FRP) in order to improve its performance, as additional structural parts such as steel plates and base materials (existing structures) The joints are bolted or welded. However, in t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04G23/02B29C65/48B29C70/12B29C70/18B29C70/44C09J7/21C09J201/00

CPCB29C70/44E04G2023/0251E04G23/0218B29C70/547C09J5/00E04G23/02B29C65/48B29C70/12B29C70/18C09J201/00C09J7/21

Inventor 松井孝洋越智宽中村一史松本幸大

Owner TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com