Manual tool sharpening and grinding equipment based on high-precision multi-station machining technology

A processing technology, multi-station technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problem of large blade angle, length consistency error, low degree of automation and production efficiency, and poor sharpness. Advanced problems, to achieve the effect of improving production efficiency, reducing labor intensity, and high sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings.

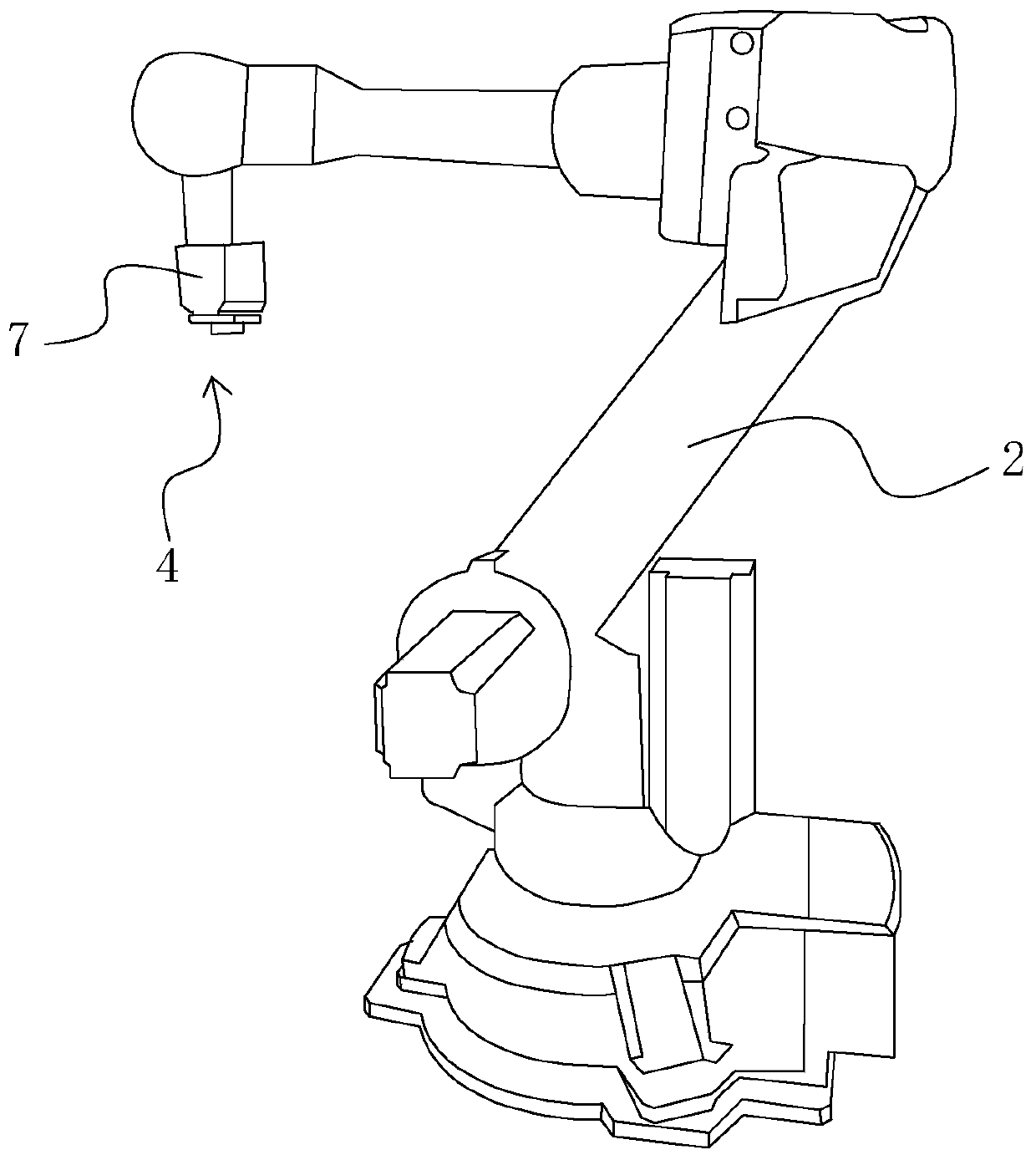

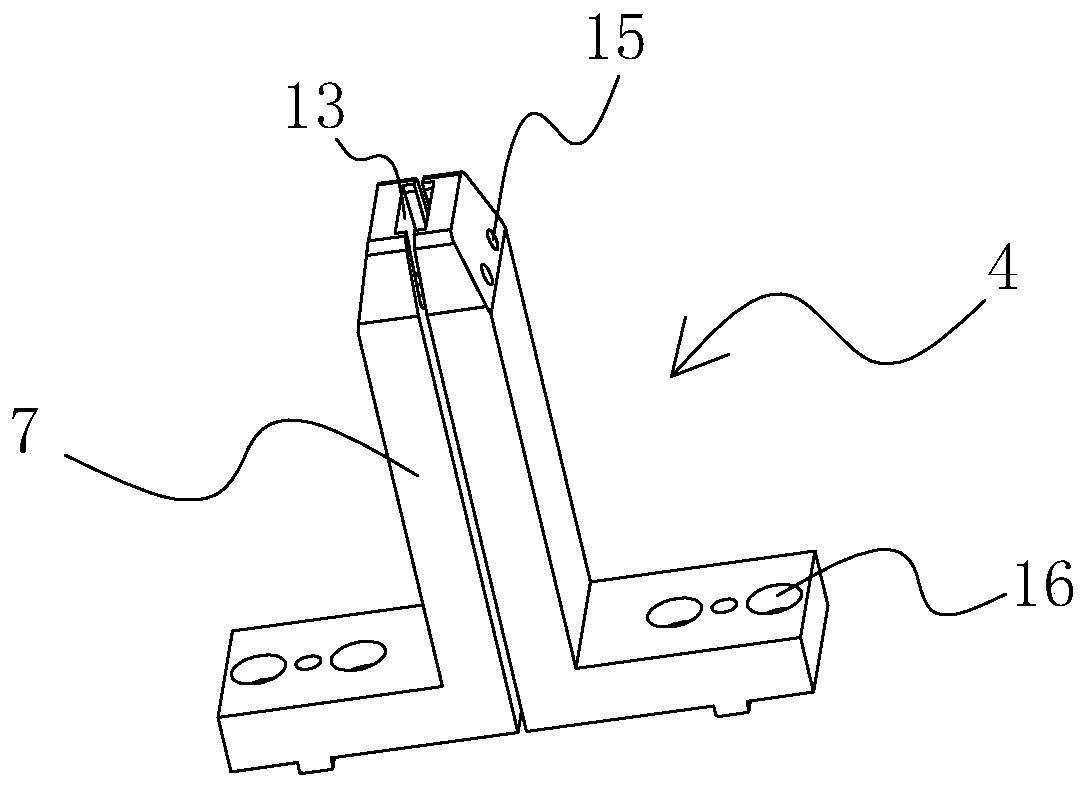

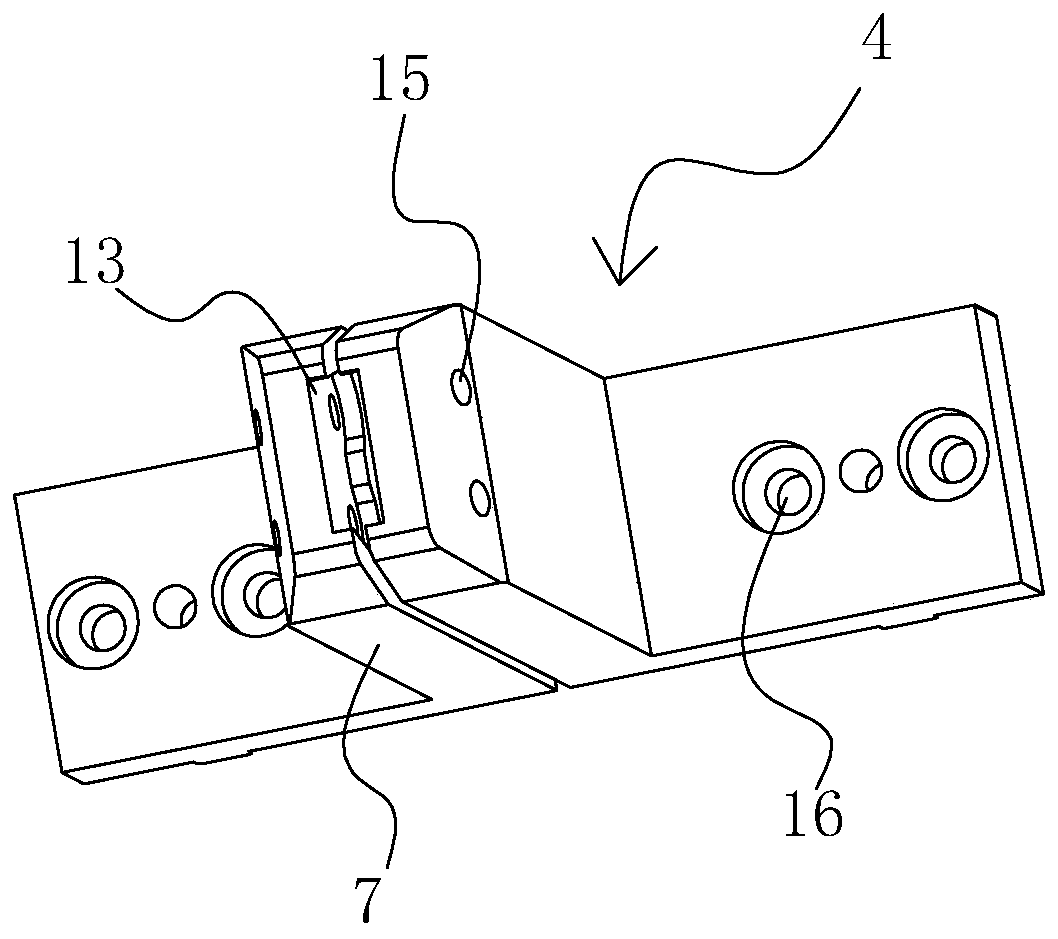

[0029] Such as figure 1 , figure 2 , Figure 4 As shown, a manual tool sharpening and grinding equipment based on high-precision multi-station processing technology includes a feeding base 1 and a mechanical arm 2. The top of the mechanical arm 2 is provided with an automatic clamping and placing assembly 4 for clamping and placing tools. , The top of the loading base 1 is provided with a tool holder rotating assembly 5 that is used to transport tools and can rotate in the circumferential direction. The tool holder rotating assembly 5 corresponds to the position of the automatic clamping and placing assembly 4. The automatic clamping assembly 4 includes a plurality of tool clamping blocks 7 arranged at the top of the mechanical arm 2 and capable of reciprocating linearly. The tool clamping block 7 is provided with a tool clamping groove 13 at one end away from the mechanical arm 2. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com