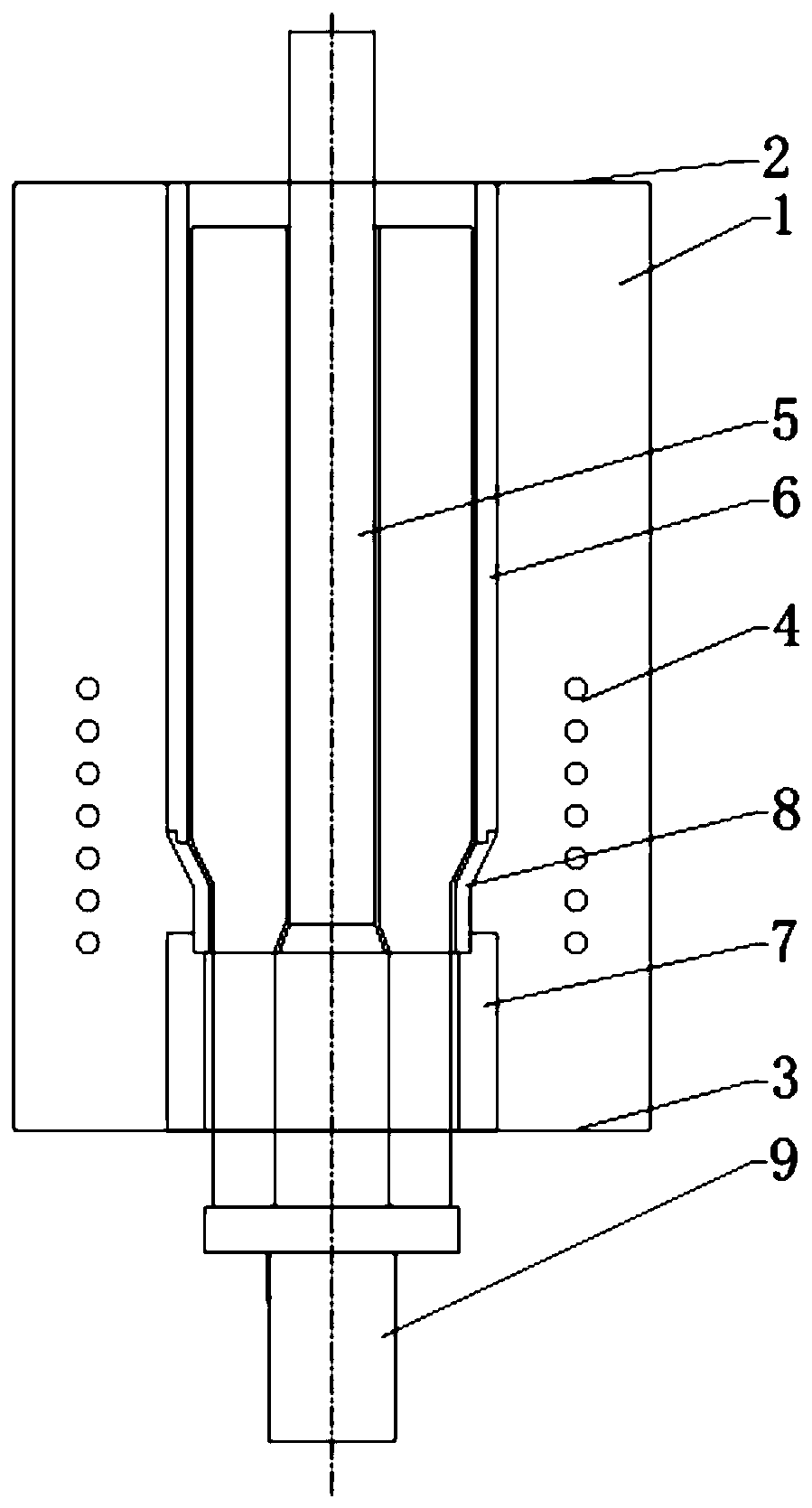

Quartz thick-walled tube secondary moulding device, and moulding method

A secondary molding, thick-walled tube technology, applied in the field of quartz tubes, can solve the problems of thick-walled tube wall thickness restrictions, and achieve the effects of improving quality, facilitating operation, and reducing bubble defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] use The quartz tube is used as the raw material, which is successfully reshaped into quartz thick-walled tube. The feeding speed is 18-24mm / min, and the discharging speed is 20-30mm / min.

Embodiment 2

[0049] use The quartz tube is used as the raw material, which is successfully reshaped into quartz thick-walled tube. The feeding speed is 20-25mm / min, and the discharging speed is 18-24mm / min.

Embodiment 3

[0051] use The quartz tube is used as the raw material, which is successfully reshaped into quartz thick-walled tube. The feeding speed is 20-25mm / min, and the discharging speed is 24-30mm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com