Supersonic ultrahigh pressure carbon dioxide compressor unit

A technology of carbon dioxide and ultra-high pressure, applied in the direction of supersonic pumps, machines/engines, mechanical equipment, etc., to achieve high safety, improve industrial application, and solve the effect of starting difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

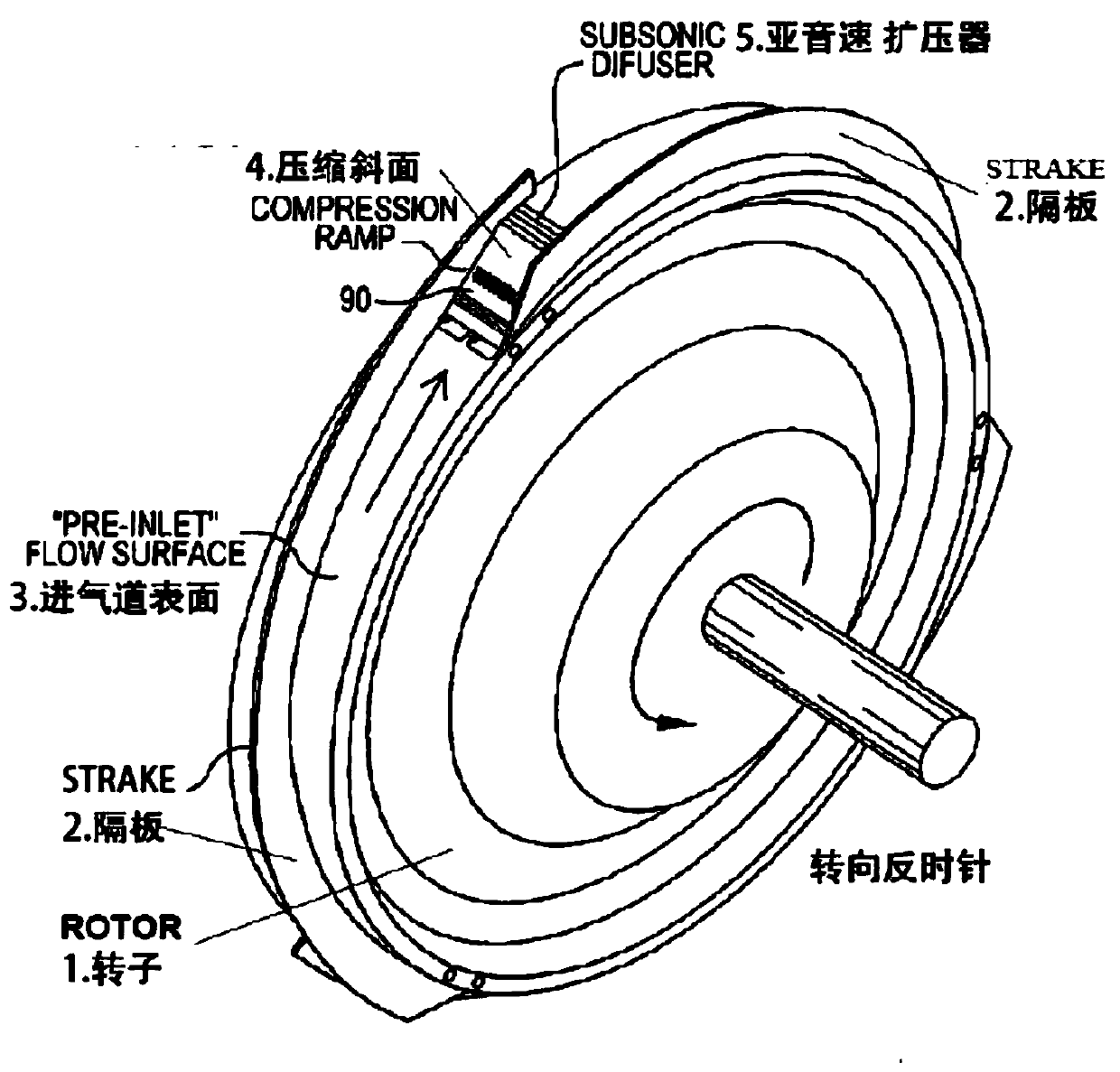

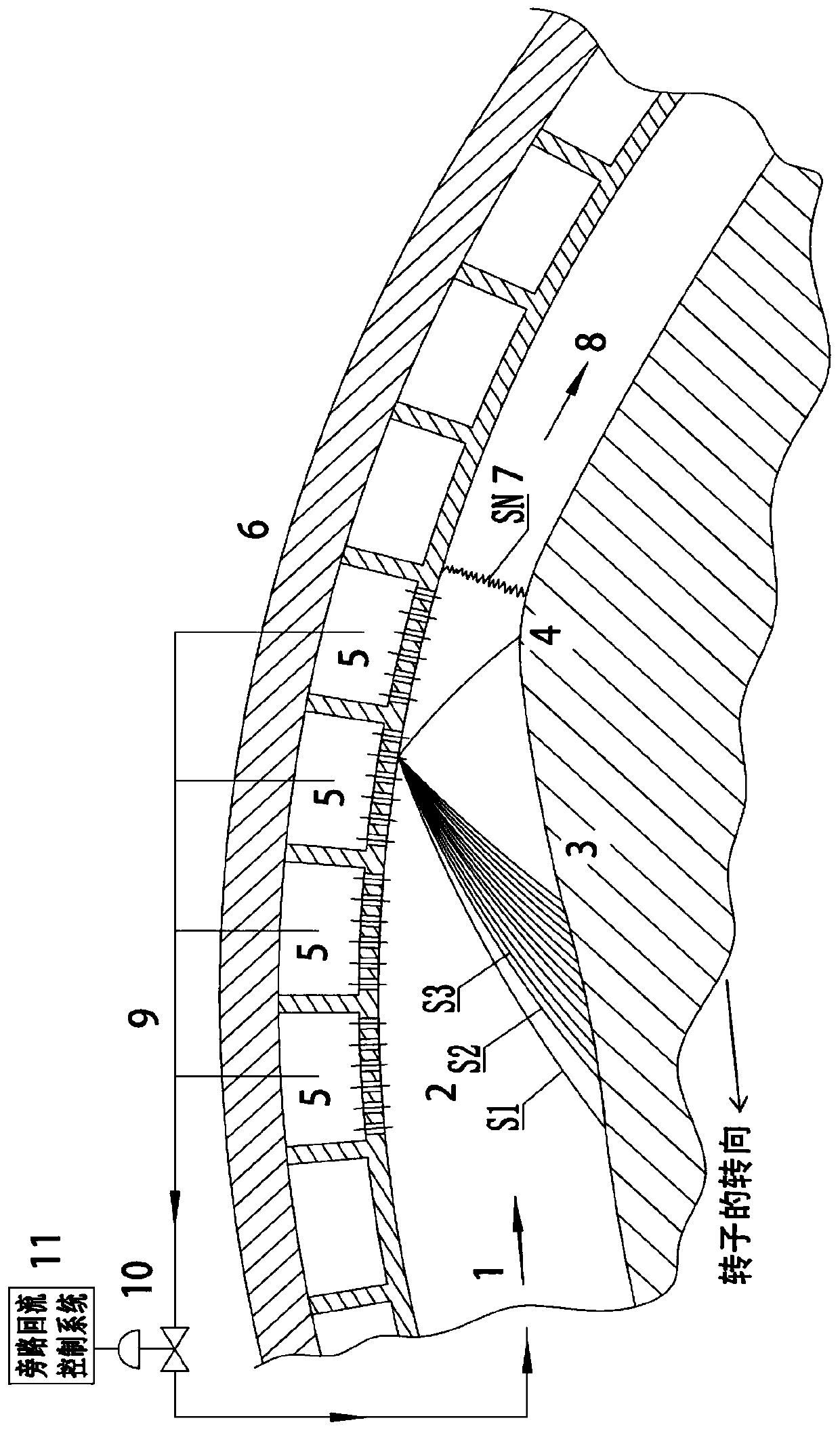

Method used

Image

Examples

Embodiment Construction

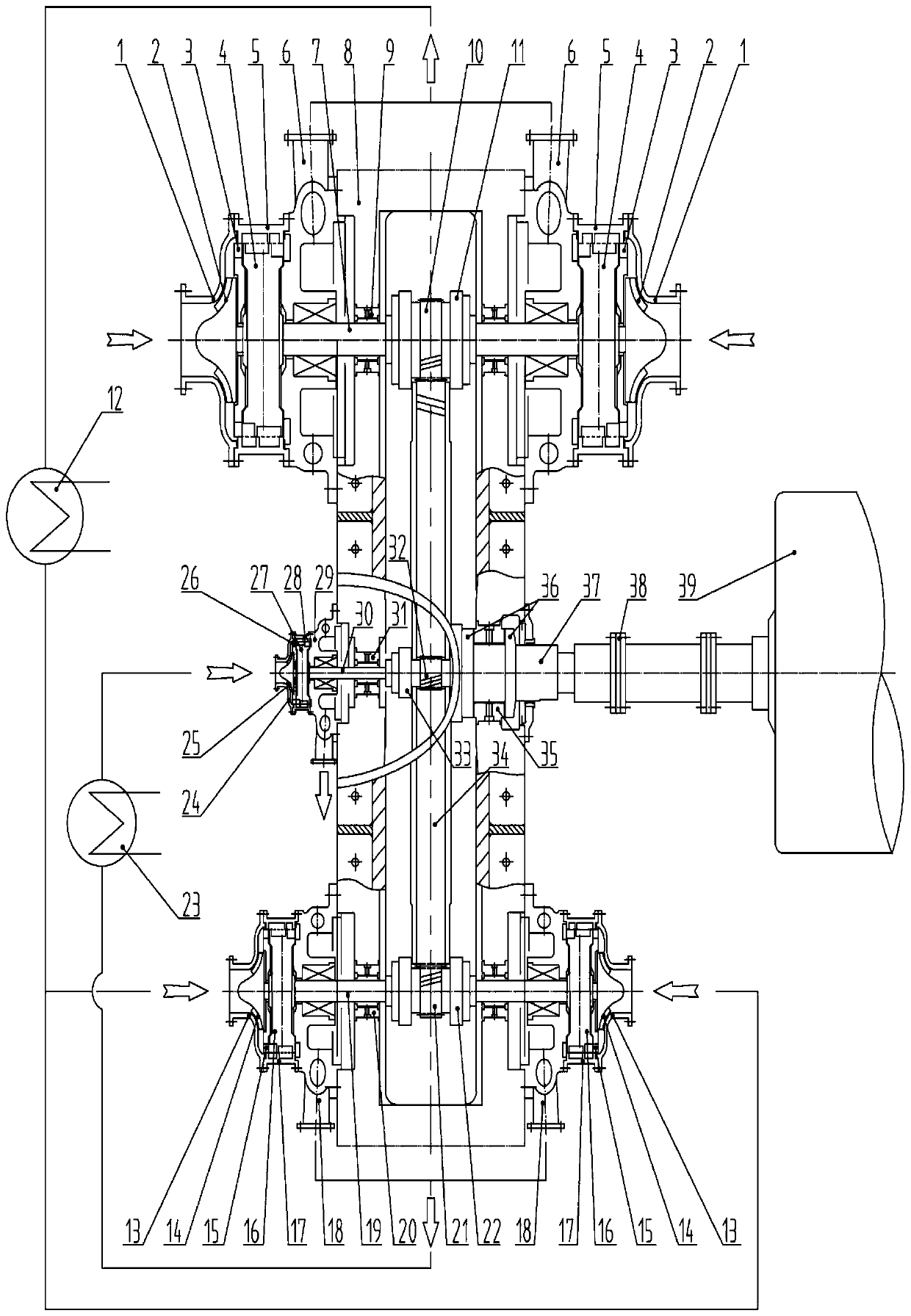

[0084] In order to understand the present invention more clearly and quantitatively, it is now attached to this description. image 3 As an example, a detailed technical solution of the present invention is given.

[0085] To extract oil from an ultra-deep reservoir on an offshore oil production platform, CO at a pressure of 52MPa.A needs to be injected 2 Gas, the inlet pressure of the compressor is 0.13MPa.A. Three-stage supersonic CO 2 For the compressor unit scheme, the pressure drop of the two intercoolers is 0.32MPa, which is equivalent to the outlet pressure of the final stage being 52.32MPa.A, and the total pressure ratio is 402.46. Regarding the distribution scheme of the pressure ratios of each stage, in order to keep the diameter of the final stage rotor from being too small, the pressure ratio of the first stage is made too small, and the pressure ratio of the last stage is made larger. The pressure ratios of each stage are as follows: 6.8, 7.3 , 8.11.

[0086] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com