A radial insertion self-locking quick joint suitable for the assembly of space truss structures

A space truss and self-locking technology, which is applied in the direction of building construction and construction, can solve the problems of insufficient dexterity of robot operation, difficulty in long-term operation of personnel, and low efficiency of assembly methods, so as to facilitate efficient one-handed operation and high precision The effect of stable connection and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

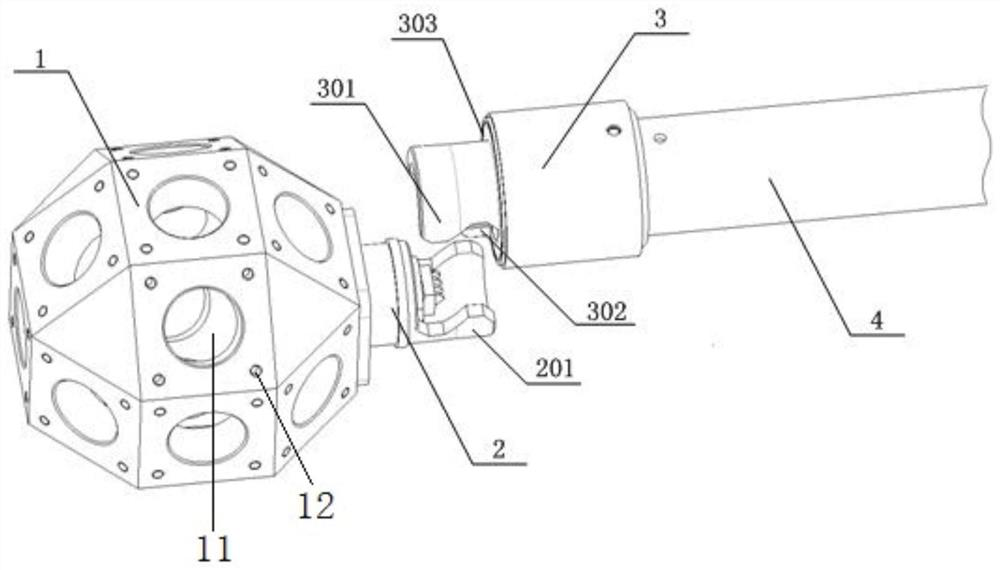

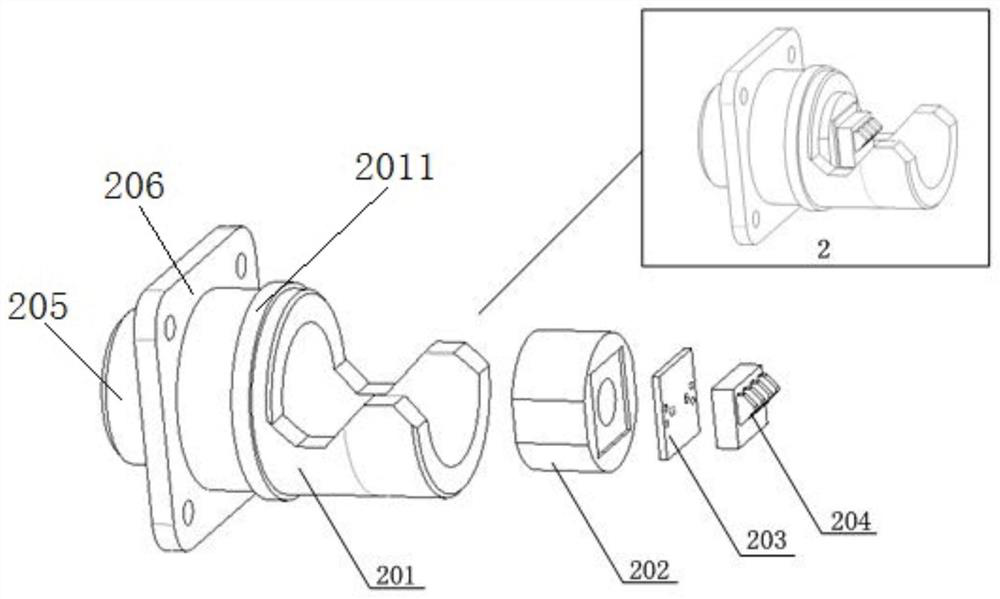

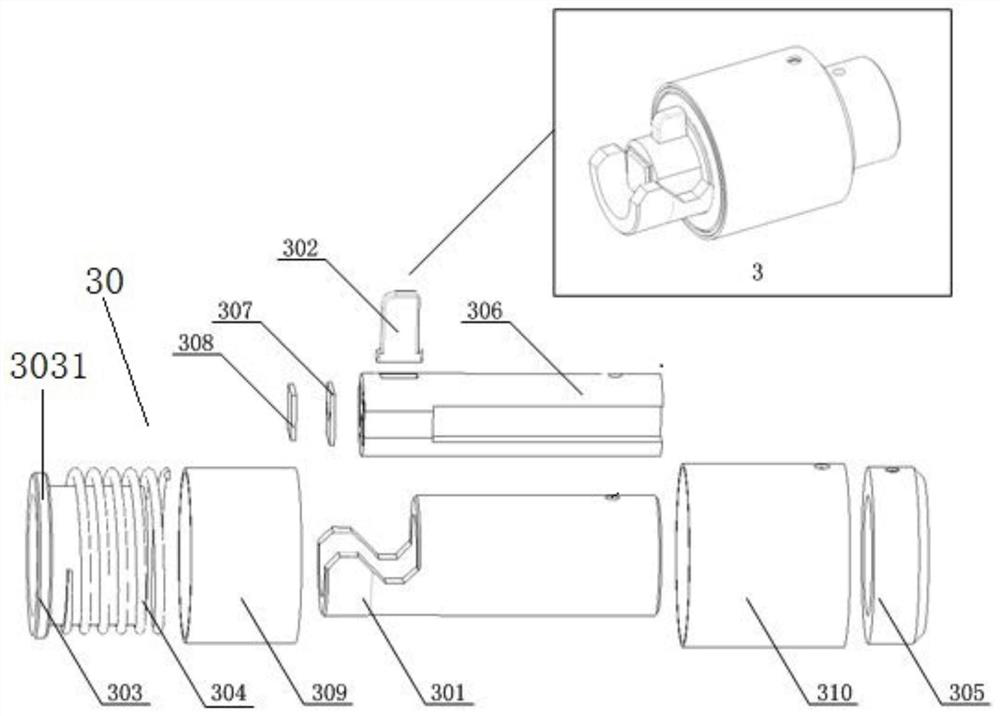

[0052] Such as figure 1 As shown, this example provides a radial insertion self-locking quick joint suitable for the assembly of space truss structures, mainly including node joints 2 and rod joints 3 . Wherein, the node joint 2 is connected with the truss node 1 to form a node joint assembly, and the bar joint 3 is connected with the truss bar 4 to form a bar joint assembly. The node connecting piece 201 in the node joint 2 and the bar connecting piece 301 in the bar joint have the same shape structure, and have matching concave-convex structures in the same lateral direction to achieve axial connection. When the node joint assembly and the bar joint assembly After close contact along a specific radial direction, when the axes, bumps, and surfaces of the node connector 201 and the rod connector 301 are completely coincident, the locking ring 303 of the rod joint 3 pops up to surround and lock the node connector 201 and the rod connector 301 , to achieve a circumferential loc...

Embodiment 2

[0059] This embodiment provides a case of using the connector of the present invention to realize quick connection of the connector.

[0060] Such as Figure 4 As shown, this example reveals the state of the connector before it is assembled and connected. The truss node 1 is pre-connected with the node joint 2 as a node joint assembly 5, and the truss node 1 is fixed; the bar joint 3 and the truss bar 4 are pre-connected as a bar joint assembly 6. The node joint assembly 5 is parallel to the axis of the rod joint assembly 6, and the tooth grooves of the node connector 201 and the rod connector 301 are complementary to each other. At this time, the rod lock tongue 302 pops up, and its side blocks the locking ring 303 from popping up.

[0061] Such as Figure 5 As shown, this example reveals the joint assembly connection process status. The middle part of the truss member 4 is grasped and pressed down by a human hand or a robot hand, and the rod joint assembly 6 is always kep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com