Device capable of measuring high-speed rotating dynamic seal wear characteristic

A technology of wear characteristics and high-speed rotation, which is applied to measuring devices, testing wear resistance, measuring force, etc., can solve the problems of not reaching the high speed of the aeroengine rotor, not being able to measure in real time, and for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention is described in further detail:

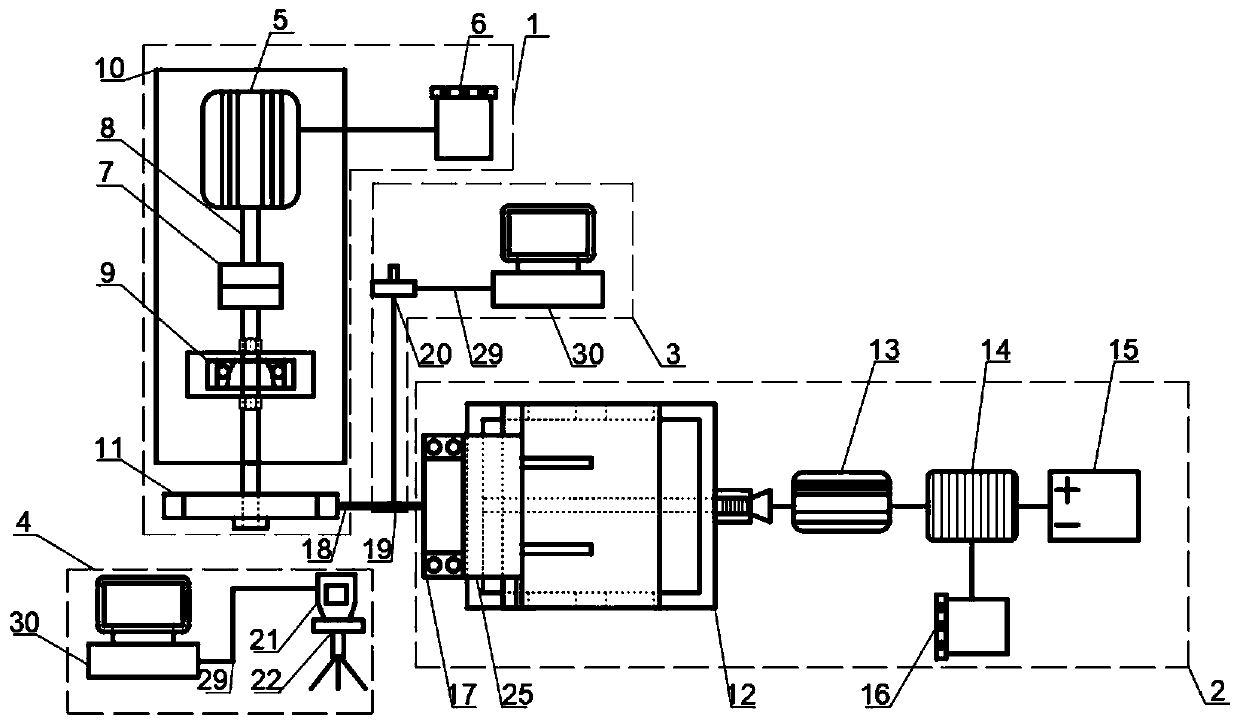

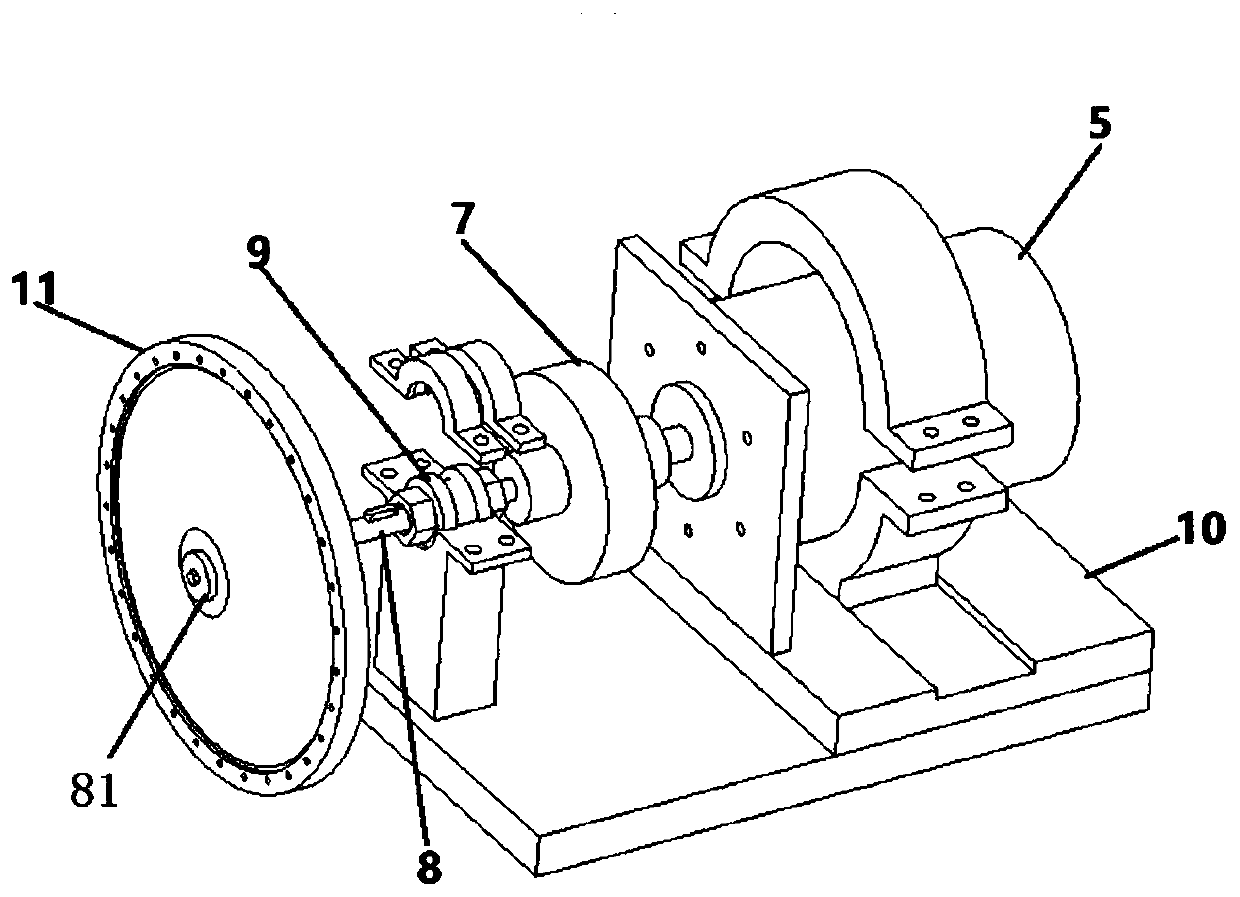

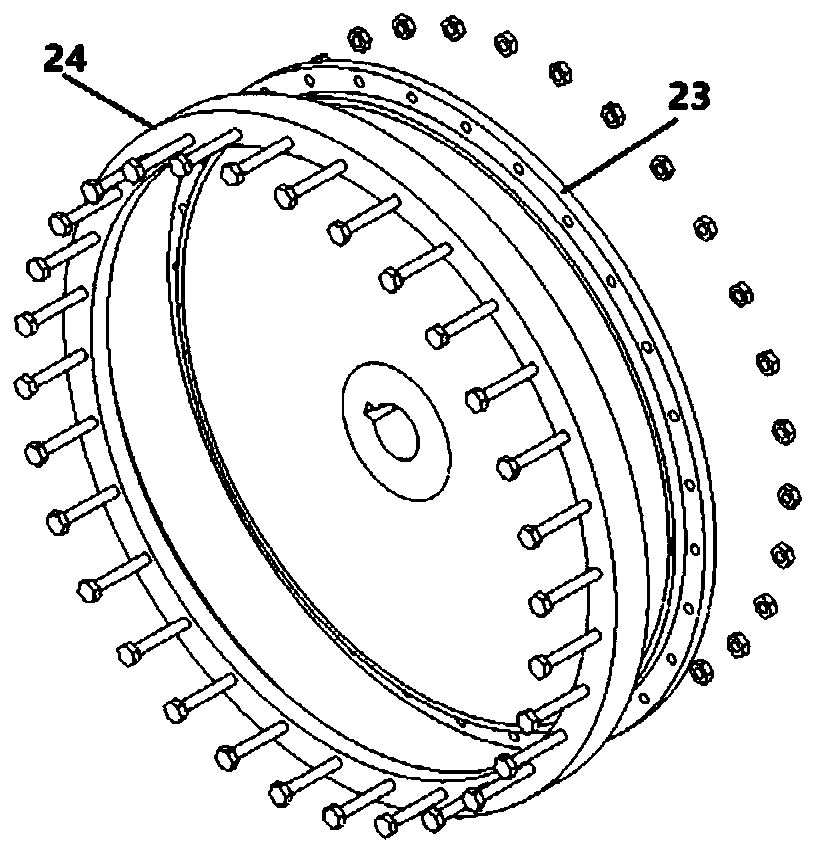

[0039] refer to Figure 1 to Figure 10 , the present invention proposes a device capable of measuring the wear characteristics of high-speed rotating dynamic seals, including four test devices: a rotation simulation device 1 , an intrusion simulation device 2 , a stress measurement device 3 and a temperature measurement device 4 . Specifically, the test device of the present invention includes a servo motor 5, a servo motor controller 6, a coupling 7, a rotating shaft 8, a grease lubricated deep groove ball bearing 9, a turntable base 10, a turntable 11, a guide rail travel module 12, and a stepping motor 13. Driver 14, DC power supply 15, stepper motor controller 16, clamping frame 17, wear test piece 18, resistance strain gauge 19, NI strain input module 20, infrared thermal imager 21, tripod 22, inner disk 23, friction Outer ring 24 , clamping frame base 25 , adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com