Two-Axis Cross-Coupling Controller Algorithm for Servo Feed System

A servo feed and cross-coupling technology, applied in program control, computer control, general control systems, etc., can solve problems such as one-way action and inability to make corresponding adjustments, and achieve the effect of improving contour accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

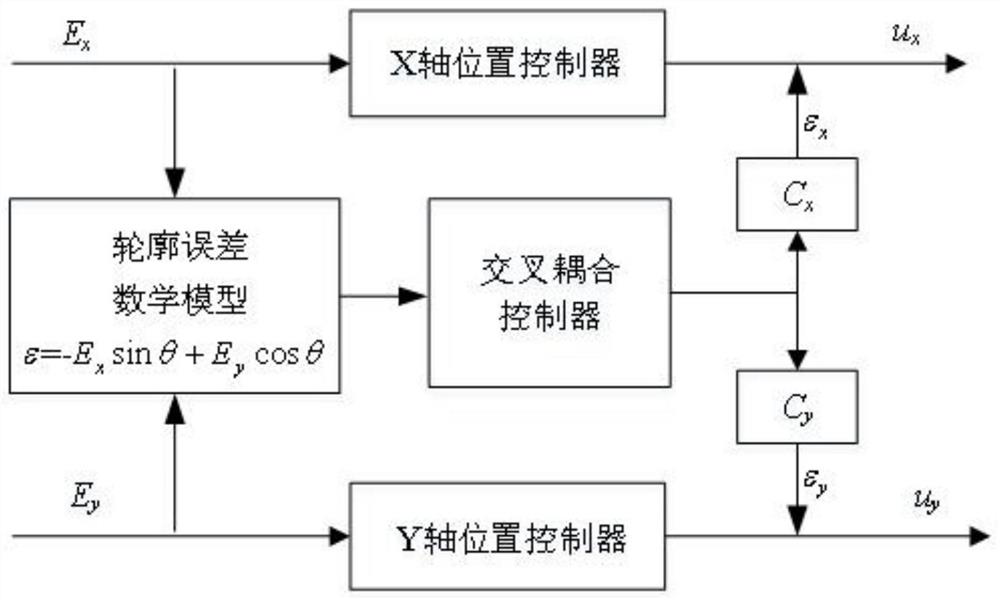

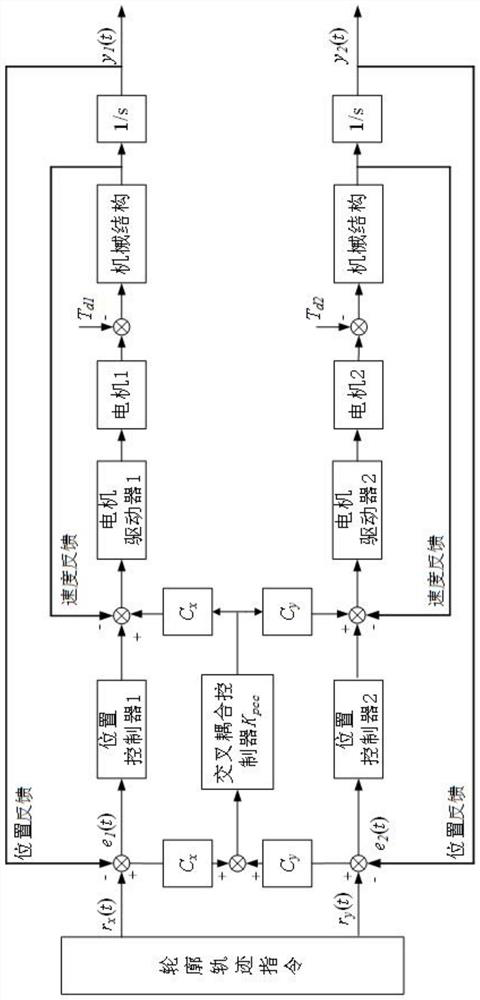

[0028] Such as figure 1 Schematic diagram of the two-axis cross-coupled controller algorithm model for the servo feed system shown. The algorithm model uses the contour error model to calculate the contour error value of the system in real time by collecting the following error signals of the X-axis and the Y-axis respectively; then the cross-coupling controller controls the contour error value to calculate the contour error value Compensation amount; after decoupling the compensation value through the compensation gain coefficient, the decoupled values are distributed to the corresponding axes in turn, so as to realize the cross-coupling control of the contour error when the two axes are linked.

[0029] A servo system two-axis cross-coupling control algorithm of the present invention, the algorithm comprises the following steps:

[0030] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com