Indexable blade grinding positioning error compensation method

A technology of positioning error and indexing blades, which is applied to the parts of grinding machine tools, grinding/polishing equipment, complex mathematical operations, etc., can solve the problems that non-standard blades cannot be ground normally, so as to save man-hours and reduce work intensity , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0020] Such as Figure 1-7 As shown, the indexable insert grinding positioning error compensation method includes the following steps:

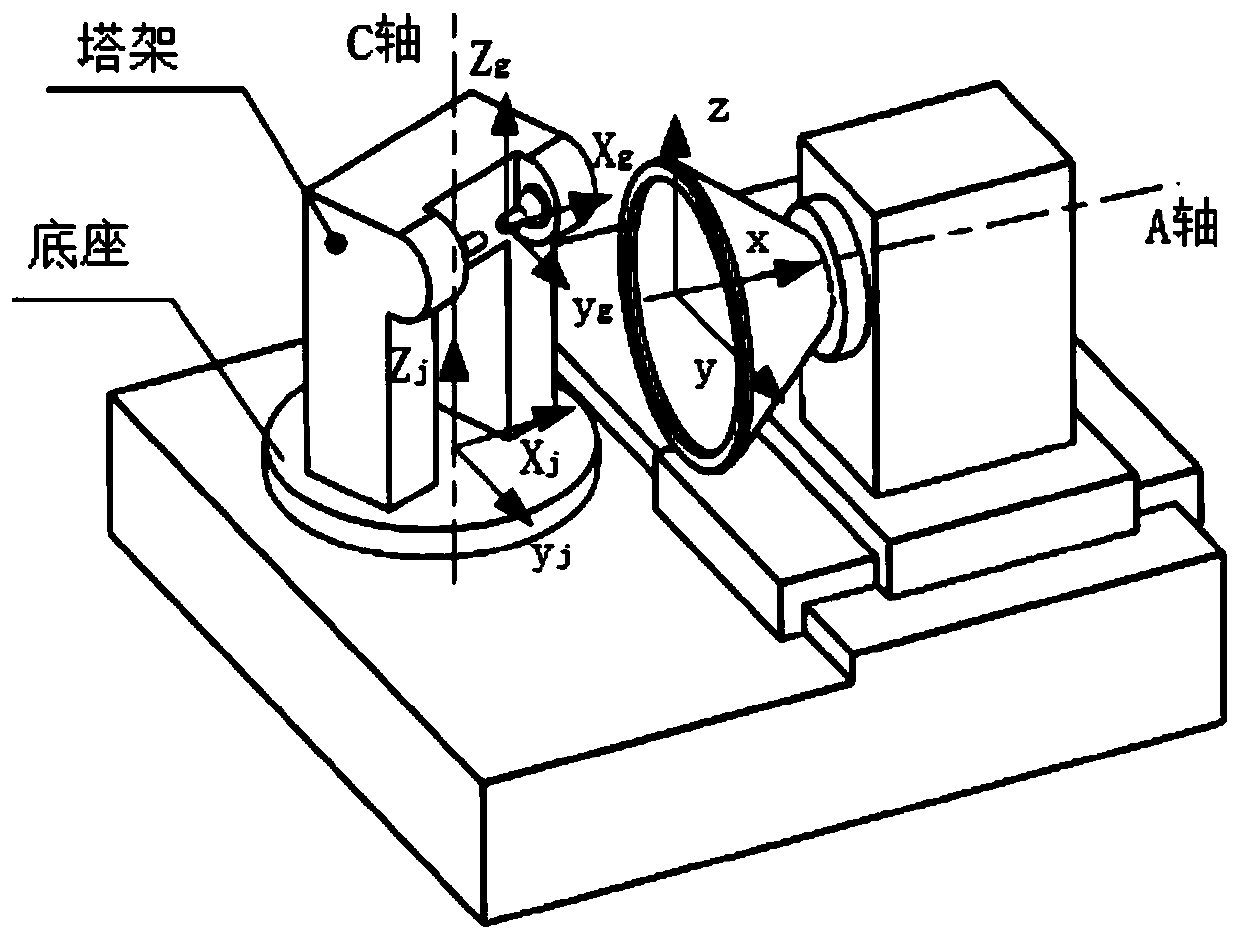

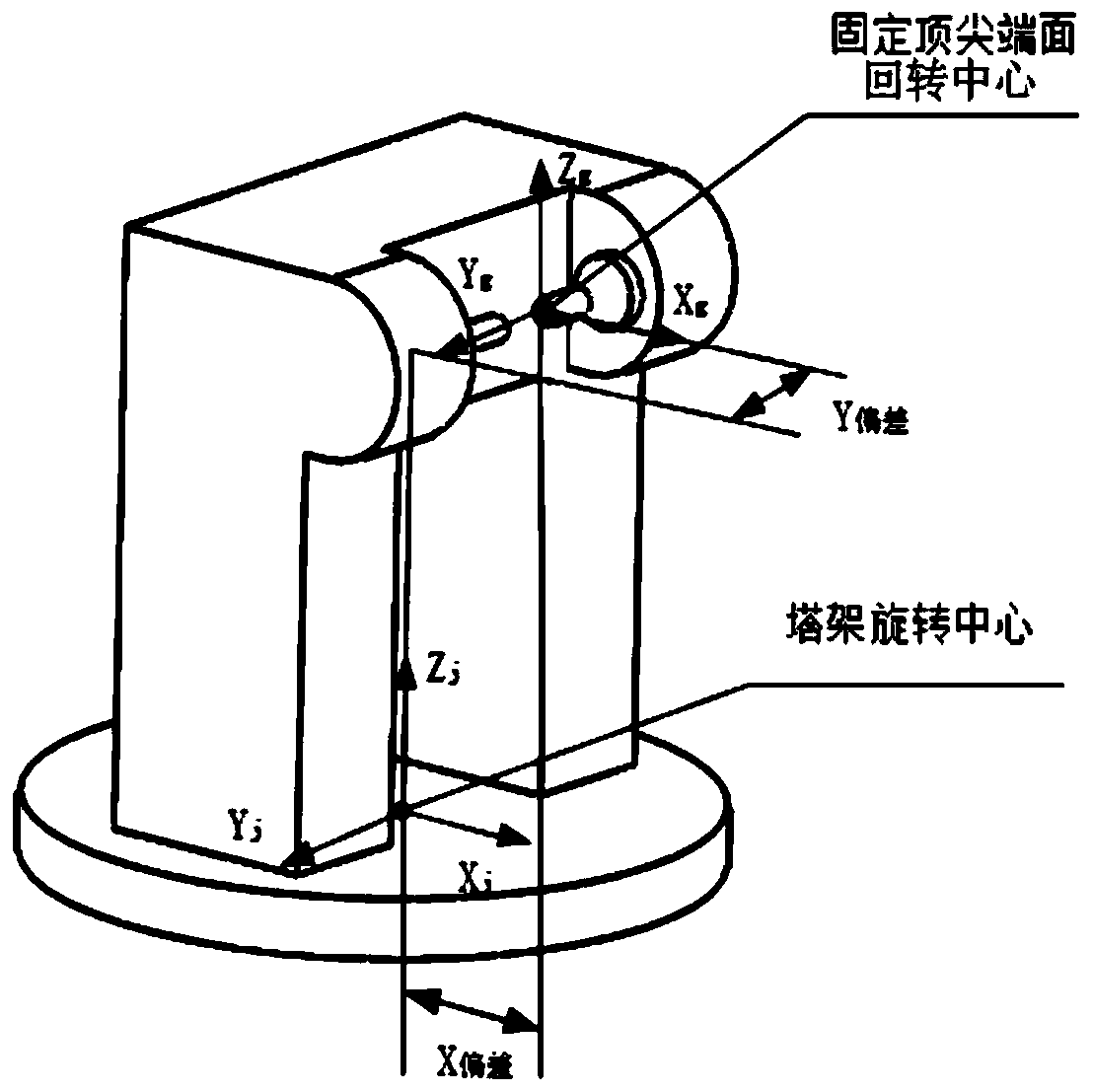

[0021] 1) Establish the workpiece coordinate system {x g ,y g ,z g}, the tower coordinate system {x j ,y j ,z j}, the machine tool coordinate system {x, y, z} whose origin is the intersection point of the grinding wheel rotation axis A-axis and the plane where the grinding wheel end face is located, and make the workpiece coordinate system, tower coordinate system and machine tool coordinate system X-axis, Y-axis, The direction of the Z axis is the same;

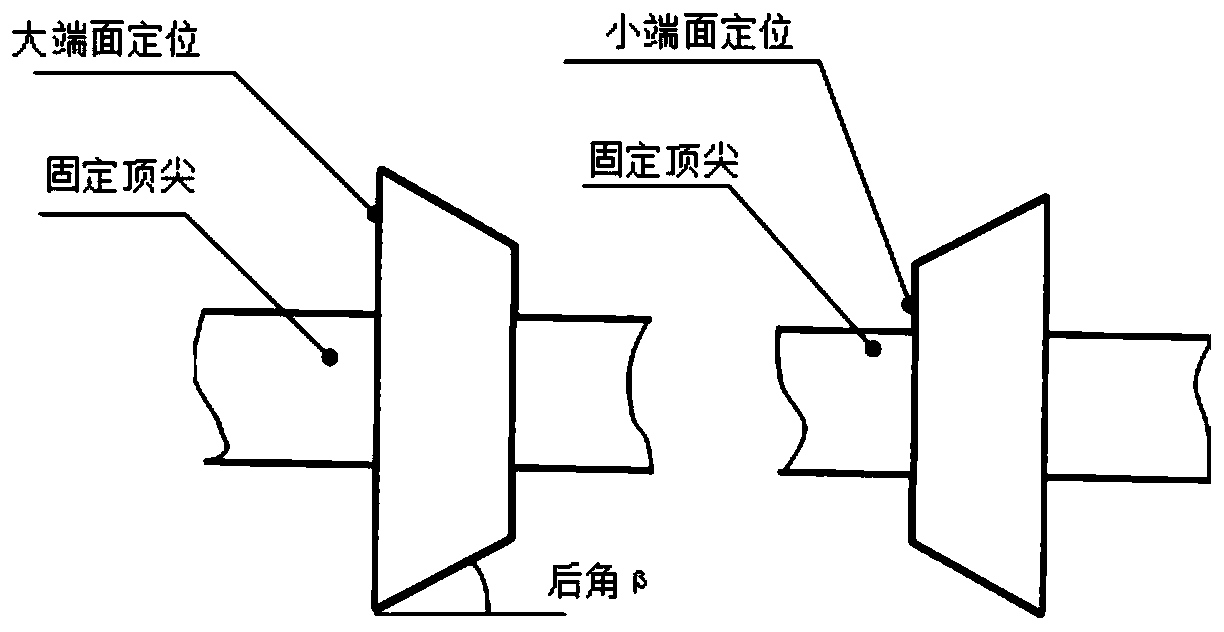

[0022] 2) Position the standard square insert with a relief angle of β on the large end face and the small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com