Production process of tempered glass

A production process and technology of tempered glass, applied in glass production, glass tempering, glass manufacturing equipment and other directions, can solve the problems of not being able to meet the compressive stress layer well, not well reaching the glass softening temperature, etc. Thermal shock performance, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

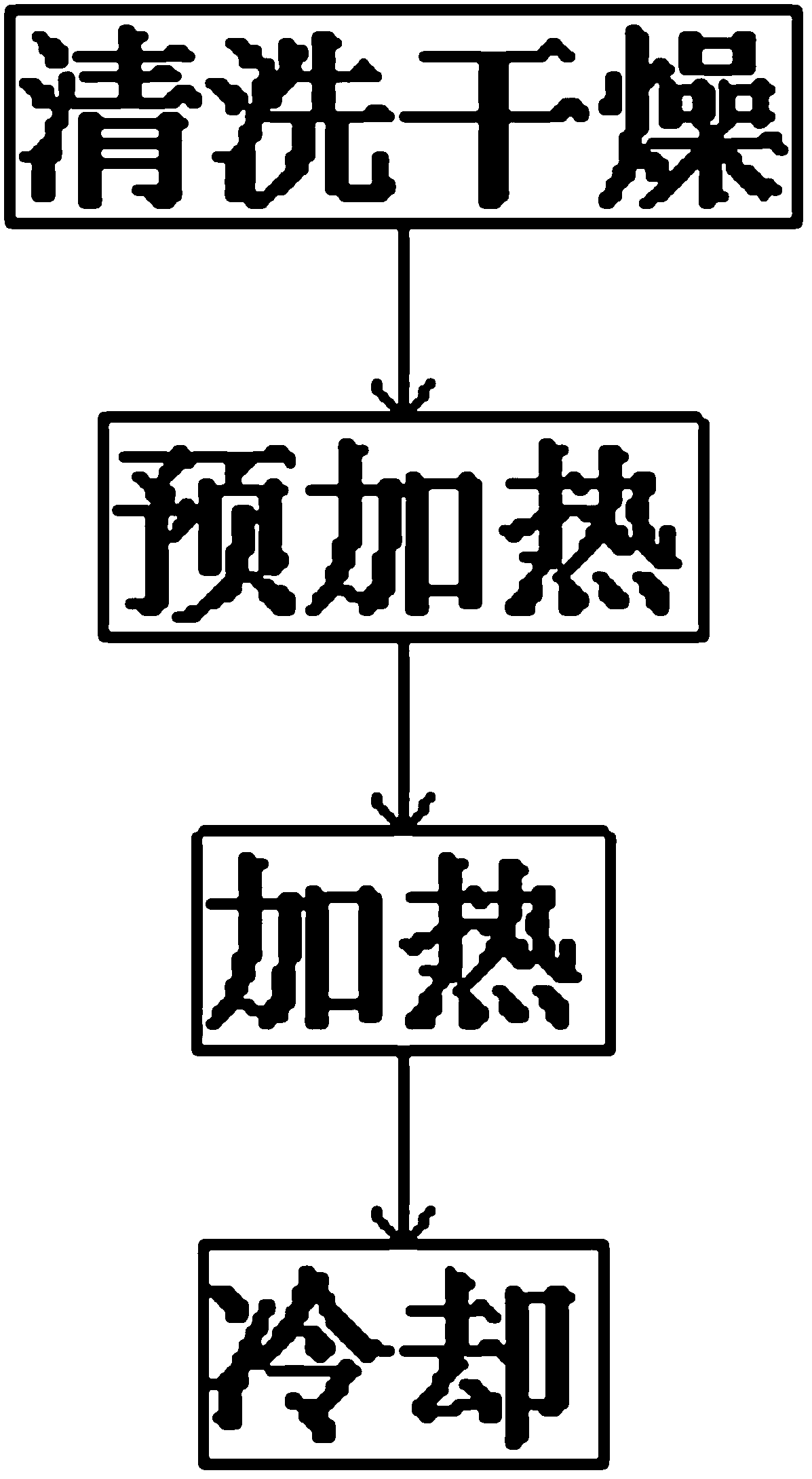

Image

Examples

Embodiment 1

[0021] A production process of toughened glass, when processing glass with a glass thickness of 6mm, the specific steps are as follows:

[0022] (1) Cleaning and drying: Clean the glass to be processed with water, and then dry it under high-pressure air for use;

[0023] (2) Preheating: Place the glass that has been cleaned and dried in step (1) in a tempering furnace, and start to heat slowly so that the temperature of the glass gradually rises from room temperature to 130°C for 2.7 minutes;

[0024] (3) Heating: Place the preheated glass in step (2) in a motor heating furnace, the heating temperature is 710°C, and the running time is 180 seconds;

[0025] (4) Cooling: Move the heated glass in step (3) into the air grid, use high-pressure normal temperature air for rapid cooling, blow the glass for 80 seconds, and then place it at natural temperature to cause tempering stress on the glass.

[0026] The testing methods for mechanical strength and thermal shock resistance are:...

Embodiment 2

[0034] A production process of toughened glass, when processing glass with a glass thickness of 6mm, the specific steps are as follows:

[0035] (1) Cleaning and drying: Clean the glass to be processed with water, and then dry it under high-pressure air for use;

[0036] (2) Preheating: Place the glass that has been cleaned and dried in step (1) in a tempering furnace, and start to heat slowly so that the temperature of the glass gradually rises from room temperature to 130°C for 2.7 minutes;

[0037] (3) Heating: Place the preheated glass in step (2) in a motor heating furnace, the heating temperature is 680°C, and the running time is 180 seconds;

[0038] (4) Cooling: Move the heated glass in step (3) into the air grid, use high-pressure normal temperature air for rapid cooling, blow the glass for 80 seconds, and then place it at natural temperature to cause tempering stress on the glass.

[0039] The tempered glass produced in Examples 1 and 2 was tested for mechanical str...

Embodiment 3

[0044] A production process of toughened glass, when processing glass with a glass thickness of 6mm, the specific steps are as follows:

[0045] (1) Cleaning and drying: Clean the glass to be processed with water, and then dry it under high-pressure air for use;

[0046] (2) Preheating: Place the glass that has been cleaned and dried in step (1) in a tempering furnace, and start to heat slowly so that the temperature of the glass gradually rises from room temperature to 130°C for 2.7 minutes;

[0047] (3) Heating: Place the preheated glass in step (2) in a motor heating furnace, the heating temperature is 710°C, and the running time is 180 seconds;

[0048] (4) Cooling: Move the heated glass in step (3) into the air grid, use high-pressure normal-temperature wind for rapid cooling, blow the glass for 260 seconds, and then place it at natural temperature to cause tempering stress on the glass.

[0049] The tempered glass produced in Examples 2 and 3 was tested for mechanical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com