A kind of method for preparing alkylpyrrolidone by amination of 1,4-butanediol

A technology of alkyl pyrrolidone and butanediol amine, which is applied in the field of preparing alkyl pyrrolidone by amination of 1,4-butanediol, can solve the problems of complicated operation process, decreased safety factor of workers, etc., and achieves high catalytic efficiency and lightening efficiency. Stress, the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

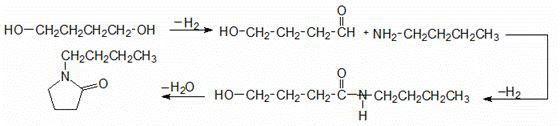

Image

Examples

Embodiment 1

[0032] A method for preparing alkylpyrrolidone by amination of 1,4-butanediol, comprising the following steps:

[0033] (1) Reaction section: The catalyst is preloaded in the reactor for reduction treatment, and then 1,4-butanediol and alkylamine are preheated to a liquid state. The two enter the mixing section and then into the reactor. The lower dehydrogenation and amination reactions are converted into N-alkylpyrrolidone crude materials, which are discharged through the material outlet of the reactor; the catalyst is a supported copper-based composite catalyst;

[0034] (2) Gas-liquid separation section: The N-alkylpyrrolidone crude material discharged from step (1) is exchanged with the raw material, and then passes through the first and second two-stage condensers in turn and then enters the first gas-liquid separation tank. The incompletely separated gas phase of the liquid separation tank passes through the third-stage condenser again and then enters the second gas-liqu...

Embodiment 2

[0044] A method for preparing alkylpyrrolidone by amination of 1,4-butanediol, comprising the following steps:

[0045] (1) Reaction section: The catalyst is preloaded in the reactor for reduction treatment, and then 1,4-butanediol and alkylamine are preheated to a liquid state. The two enter the mixing section and then into the reactor. The lower dehydrogenation and amination reactions are converted into N-alkylpyrrolidone crude materials, which are discharged through the material outlet of the reactor; the catalyst is a supported copper-based composite catalyst;

[0046] (2) Gas-liquid separation section: The N-alkylpyrrolidone crude material discharged from step (1) is exchanged with the raw material, and then passes through the first and second two-stage condensers in turn and then enters the first gas-liquid separation tank. The incompletely separated gas phase of the liquid separation tank passes through the third-stage condenser again and then enters the second gas-liqu...

Embodiment 3

[0056] A method for preparing alkylpyrrolidone by amination of 1,4-butanediol, comprising the following steps:

[0057] (1) Reaction section: The catalyst is preloaded in the reactor for reduction treatment, and then 1,4-butanediol and alkylamine are preheated to a liquid state. The two enter the mixing section and then into the reactor. The lower dehydrogenation and amination reactions are converted into N-alkylpyrrolidone crude materials, which are discharged through the material outlet of the reactor; the catalyst is a supported copper-based composite catalyst;

[0058](2) Gas-liquid separation section: The N-alkylpyrrolidone crude material discharged from step (1) is exchanged with the raw material, and then passes through the first and second two-stage condensers in turn and then enters the first gas-liquid separation tank. The incompletely separated gas phase of the liquid separation tank passes through the third-stage condenser again and then enters the second gas-liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com