A kind of catalyst of propane dehydrogenation to propylene and its preparation and application

A propane dehydrogenation and catalyst technology, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of platinum carbon deposition and deactivation of active center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

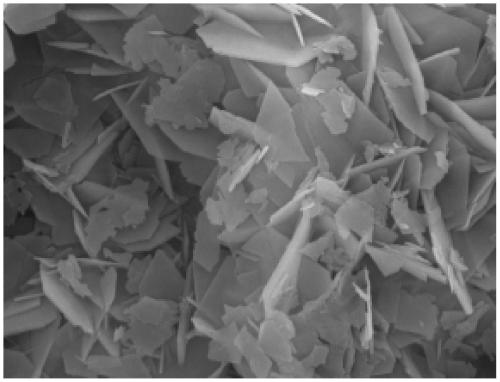

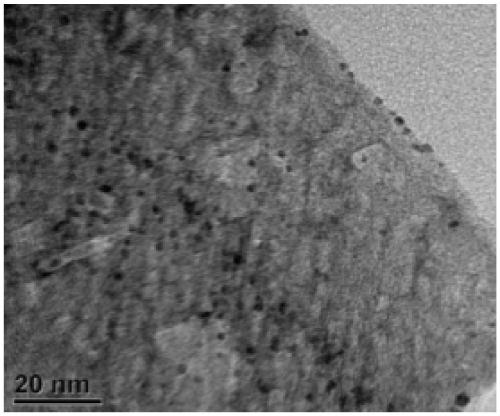

[0042] This embodiment prepares catalyst 1Pt-In-V / Al 2 o 3 (2D), and its catalytic performance in propane dehydrogenation to propylene was tested.

[0043] preparation:

[0044] (1) First, 8.4 g of NaOH powder was gradually dissolved in 100 g of deionized water, and stirred by magnetic force to obtain a clear and transparent solution.

[0045] Next, the mass of 19g of Al (NO 3 ) 3 9H 2 O powder was gradually added to the solution, and the clear solution gradually turned into a white cloudy liquid. After stirring at room temperature for 6 hours, the solution was transferred to a crystallization tank, aged at 170° C. for 24 hours, and washed by centrifugation several times. After drying at 80°C for 24 hours, and then roasting in a muffle furnace at 550°C, the final alumina sample was obtained, numbered Al 2 o 3 (2D).

[0046](2) Mix 0.0089g indium trichloride (US SIGMA-ALDRICH company, analytically pure) and 0.008g chloroplatinic acid hexahydrate (Sinopharm Chemical Rea...

Embodiment 2

[0050] This embodiment prepares catalyst 2Pt-In-Co / Al 2 o 3 (2D), and its catalytic performance in propane dehydrogenation to propylene was tested.

[0051] Preparation: The preparation method is the same as in Example 1, but the second auxiliary agent of the catalyst is different. The catalyst 2 is prepared with cobalt nitrate hexahydrate (Sinopharm Chemical Reagent Co., Ltd., analytically pure), and its composition is Pt-In-Co / Al 2 o 3 (2D).

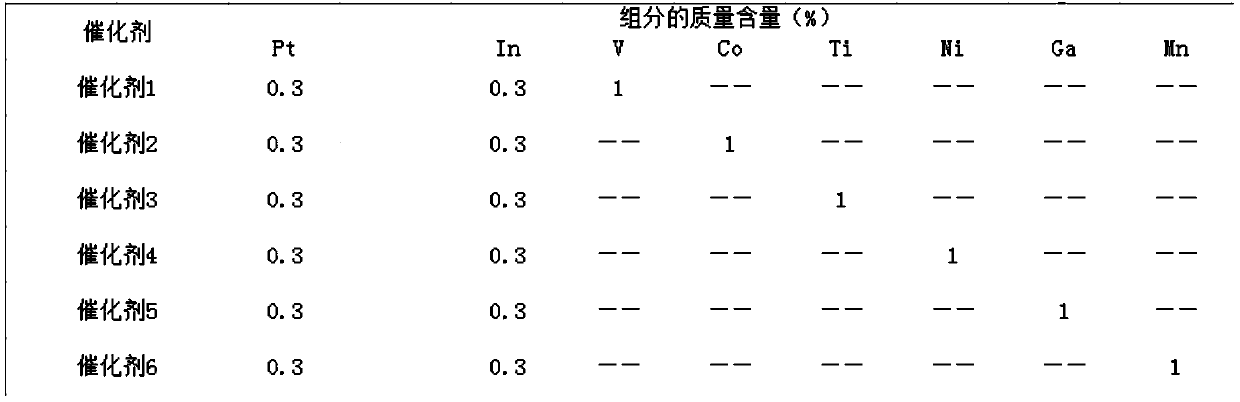

[0052] Based on the total mass of catalyst 2, the mass content of each component in catalyst 2 is shown in Table 1.

[0053] Test: Fill the catalyst 2 in the miniature fixed bed reactor, the mass of the filled catalyst is 0.2g, and the volume space velocity of the propane gas is controlled to be 1000h -1 , the reaction pressure is normal pressure, the inlet temperature of the reactor is 590°C, and the reaction time is 12 hours. The reaction product is analyzed by a gas chromatograph SP-2100, and the catalyst activity obtained will ...

Embodiment 3

[0055] This embodiment prepares catalyst 3Pt-In-Ti / Al 2 o 3 (2D), and its catalytic performance in propane dehydrogenation to propylene was tested.

[0056] Preparation: The preparation method is the same as in Example 1, but the second auxiliary agent of the catalyst is different. Catalyst 3 is prepared with tetrabutyl titanate (Sinopharm Chemical Reagent Co., Ltd., analytically pure), and its composition is Pt-In-Ti / al 2 o 3 (2D).

[0057] Based on the total mass of catalyst 3, the mass content of each component in catalyst 3 is shown in Table 1.

[0058] Test: Fill the catalyst 3 in the miniature fixed bed reactor, the mass of the filled catalyst is 0.2g, and the volume space velocity of the propane gas is controlled to be 1000h -1 , the reaction pressure is normal pressure, the inlet temperature of the reactor is 590°C, and the reaction time is 12 hours. The reaction product is analyzed by a gas chromatograph SP-2100, and the catalyst activity obtained will be analyz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com