Dustproof structure for blast furnace top charging bucket

A dust-proof structure, blast furnace furnace technology, applied in the direction of the dust collector, bell and funnel arrangement, etc., can solve the problems of high labor intensity, easy to cause dust, abnormal feeding, etc., to achieve the effect of reducing dust cleaning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment, the specific embodiment of the present invention is described in further detail. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

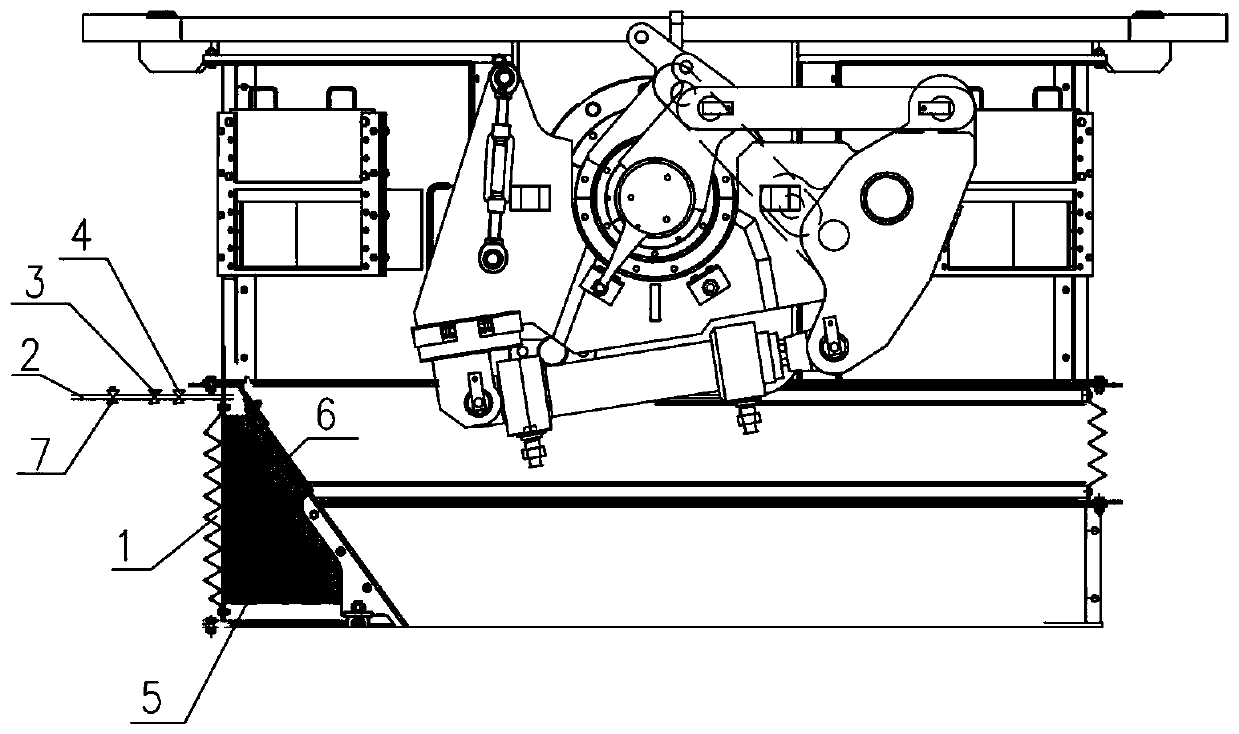

[0022] combine figure 1 As shown, the present invention provides a dust-proof structure for blast furnace roof tanks including a material accumulation platform, which is characterized in that, the outer side of the material accumulation platform adopts a bellows 1, and the bellows 1 is connected with a pipeline 2 outside the pipeline. 2 is connected with compressed air, and the pressure in the accumulating table is increased by introducing compressed air to avoid dust accumulation; the pipeline 2 is provided with a solenoid valve 3 and a pressure interlock switch 4, and the solenoid valve 3 and pressure interlock switch 4 are connected to the The background system is connected. When the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com