Beneficiation method for tungsten-tin-containing concentrate

A beneficiation method and concentrate technology are applied in the field of beneficiation of tungsten-tin concentrates, which can solve problems such as unstable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

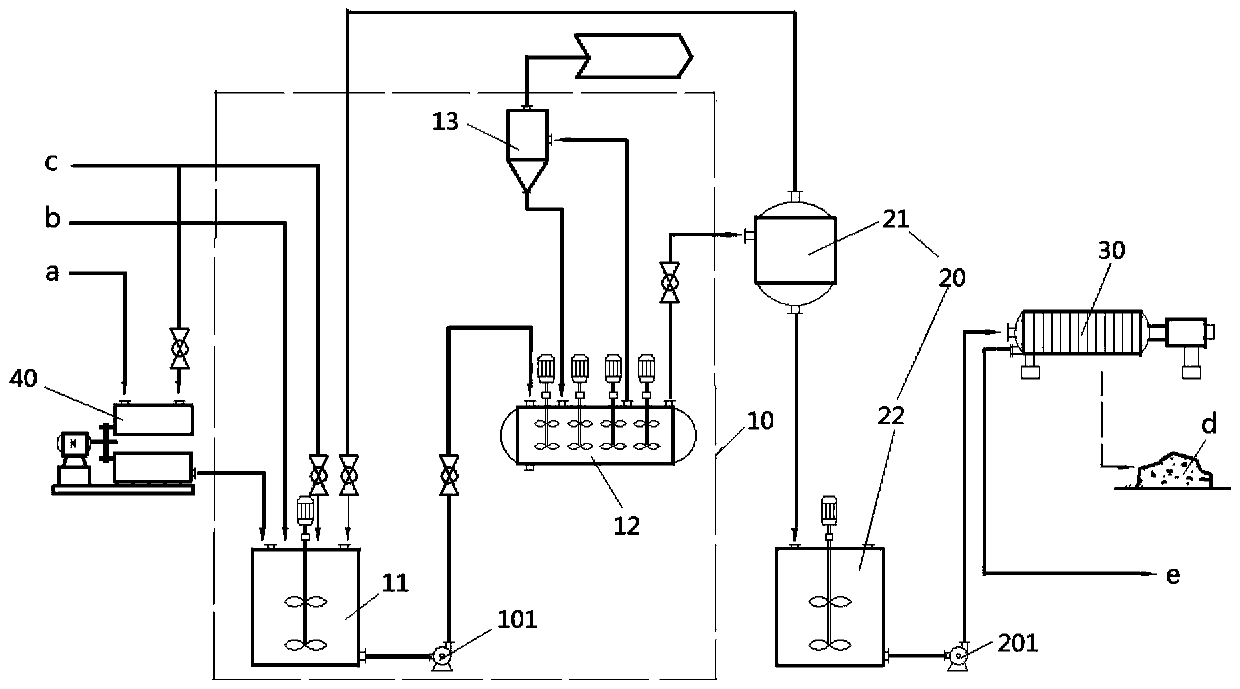

[0057] using as figure 1 The beneficiation unit shown is for beneficiation of tungsten-containing tin concentrates. specifically:

[0058] The main components of tungsten-containing tin concentrate are analyzed as follows:

[0059] element Sn WO 3

Mo CaO Fe S P As SiO 2

MgO Content wt% 34.75 9.54 0.40 14.92 6.39 0.33 0.04 0.68 1.89 0.25

[0060] The tungsten-tin concentrate was put into the ball mill at a speed of 500kg / h through a screw conveyor, and at the same time, industrial water was added to the ball mill at a speed of 250L / h for wet ball milling to make abrasives; Add sodium carbonate at a feeding speed of / h, add industrial water at a speed of 75kg / h, and mix slurry under stirring;

[0061] The prepared slurry is continuously fed into the pressure leaching tank at a flow rate of 865kg / h, and the leaching reaction is carried out under the state of stirring and electric heating. During the period, the residence ...

Embodiment 2

[0065] using as figure 1 The beneficiation unit shown is for beneficiation of tungsten-containing tin concentrates. specifically:

[0066] The concrete element analysis of tungsten-containing tin concentrate is the same as in Example 1, and the processing technique is as follows:

[0067] The tungsten-containing tin concentrate is put into the ball mill at a speed of 500kg / h through a screw conveyor, and industrial water is added to the ball mill at a speed of 1000L / h for wet ball milling to make abrasives; Add sodium carbonate at a feeding speed of / h, add industrial water at a speed of 150kg / h, and mix slurry under stirring;

[0068] The prepared slurry is continuously fed into the pressure leaching tank at a flow rate of 1950kg / h, and the leaching reaction is carried out under the state of stirring and electric heating. During the period, the residence time of the slurry in the pressure leaching kettle was 4h, the leaching temperature was 220°C, and the leaching pressure...

Embodiment 3

[0072] using as figure 1 The beneficiation unit shown is for beneficiation of tungsten-containing tin concentrates. specifically:

[0073] The concrete element analysis of tungsten-containing tin concentrate is the same as in Example 1, and the processing technique is as follows:

[0074] The tungsten-containing tin concentrate is put into the slurry tank at a speed of 500kg / h through a screw conveyor, and at the same time, sodium carbonate is added at a speed of 25kg / h, and industrial water is added at a speed of 350kg / h.

[0075] The prepared slurry is continuously fed into the pressure leaching tank at a flow rate of 875kg / h, and the leaching reaction is carried out under the state of stirring and electric heating. During the period, the residence time of the slurry in the pressurized leaching kettle was 1 h, the leaching temperature was 160 °C, and the leaching pressure was 0.6 MPa. During the leaching reaction, the generated non-condensable gas mixed with part of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com