A method of preparing diamond by using boron carbide through microwave plasma

A microwave plasma and plasma technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as insoluble boron carbide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

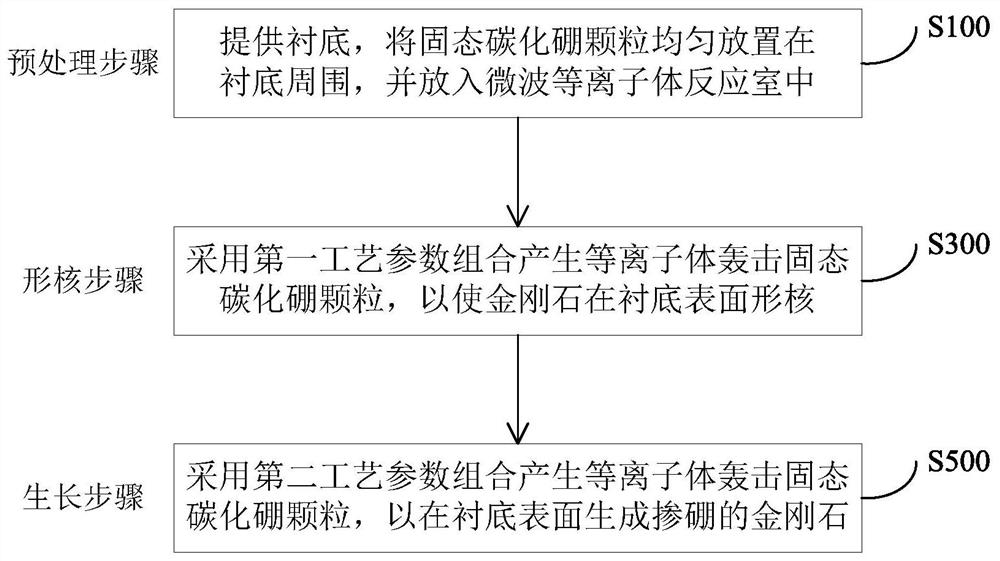

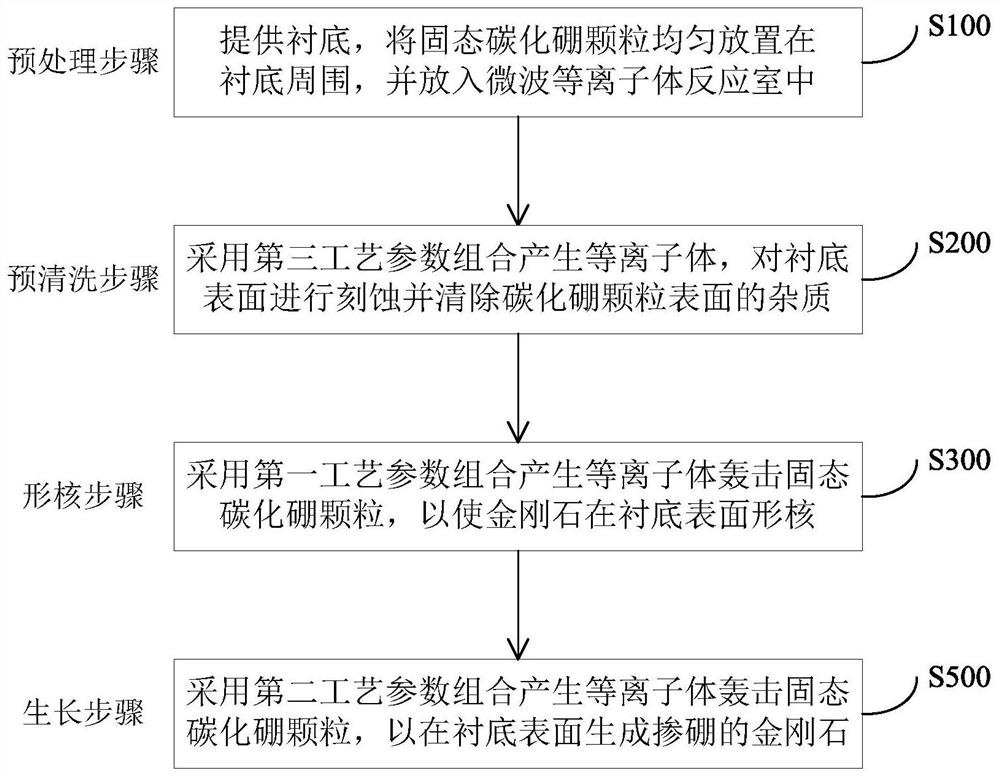

Method used

Image

Examples

Embodiment 1

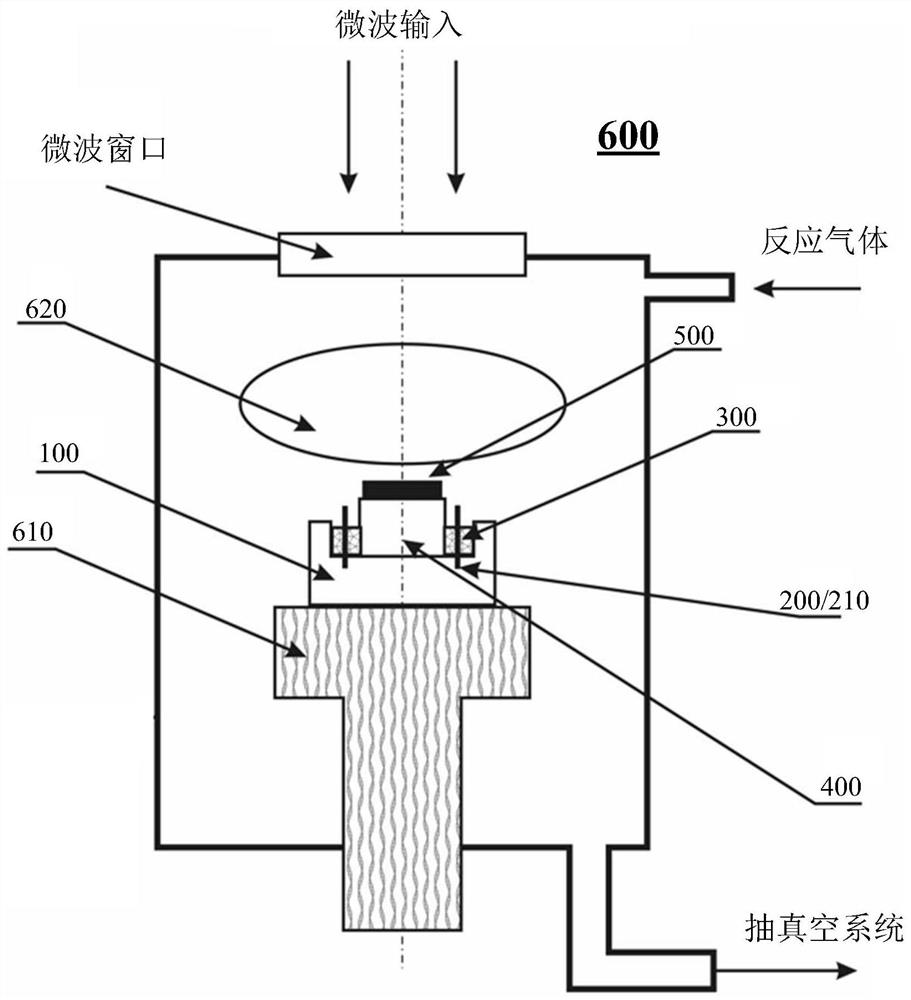

[0140] Microwave CVD system substrate table diameter is 60 mm, molybdenum disc-shaped metal container outer diameter is 60 mm, wall thickness is 3.0 mm, bottom thickness is 2.5 mm, depth is 5.0 mm; substrate material is diameter 30 mm, thickness 6.0 mm Circular monocrystalline silicon wafers, 8 jacks are symmetrically distributed on the bottom of the disc-shaped metal container with the center as the axis, the diameter of the jacks is 1.0 mm, and the depth is 1.0 mm. On a circle with a diameter of 42mm, this distance can ensure that there is an equal distance between the wire and the outer circle of the substrate material and the inner wall of the disc-shaped metal container. The length of the tungsten wire is 6.0 mm and the diameter is 1.0 mm; the wire It is uniformly filled with silicon carbide particles (99.9% pure) with a thickness of 3.0 mm.

[0141] (1) When high-purity hydrogen gas is introduced into the plasma reaction chamber until the vacuum degree is 1.5kPa, the mic...

Embodiment 2

[0146] Microwave CVD system substrate table diameter is 60 mm, molybdenum disc-shaped metal container outer diameter is 60 mm, wall thickness is 3.0 mm, bottom thickness is 2.5 mm, depth is 5.0 mm; substrate material is diameter 30 mm, thickness 6.0 mm Circular monocrystalline silicon wafers, four sockets are symmetrically distributed on the bottom of the disc-shaped metal container with the center as the axis, the diameter of the socket is 1.0 mm, and the depth is 1.0 mm. The sockets are symmetrically distributed on the center axis of the substrate table. On a circle with a diameter of 42mm, this distance can ensure that there is an equal distance between the wire and the outer circle of the substrate material and the inner wall of the disc-shaped metal container. The length of the tungsten wire is 6.0 mm and the diameter is 1.0 mm; the wire It is uniformly filled with silicon carbide particles (99.9% pure) with a thickness of 3.0 mm.

[0147] (1) When high-purity hydrogen ga...

Embodiment 3

[0152] Microwave CVD system substrate table diameter is 60 mm, molybdenum disc-shaped metal container outer diameter is 60 mm, wall thickness is 3.0 mm, bottom thickness is 2.5 mm, depth is 5.0 mm; substrate material is diameter 30 mm, thickness 6.0 mm Circular monocrystalline silicon wafers, 8 jacks are symmetrically distributed on the bottom of the disc-shaped metal container with the center as the axis, the diameter of the jacks is 1.0 mm, and the depth is 1.0 mm. On a circle with a diameter of 42mm, this distance can ensure that there is an equal distance between the wire and the outer circle of the substrate material and the inner wall of the disc-shaped metal container. The length of the tungsten wire is 6.0 mm and the diameter is 1.0 mm; the wire It is uniformly filled with silicon carbide particles (99.9% pure) with a thickness of 3.0 mm.

[0153] (1) When high-purity hydrogen gas is introduced into the plasma reaction chamber until the vacuum degree is 1.5kPa, the mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com