Device for eliminating N2O within exhaust gas and method for eliminating N2O

A technology of gas and gas flow paths, which is used in combustion methods, separation methods, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

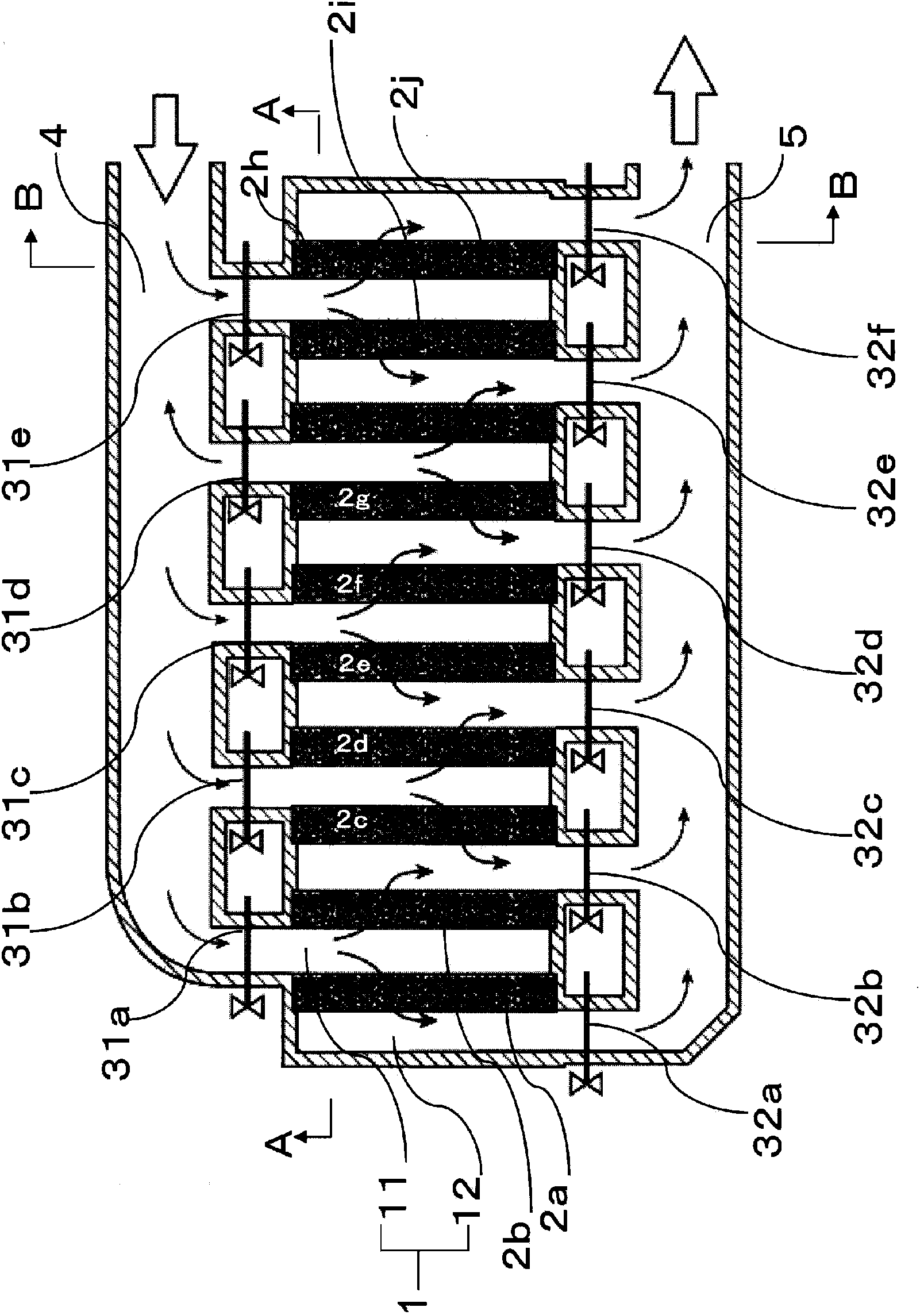

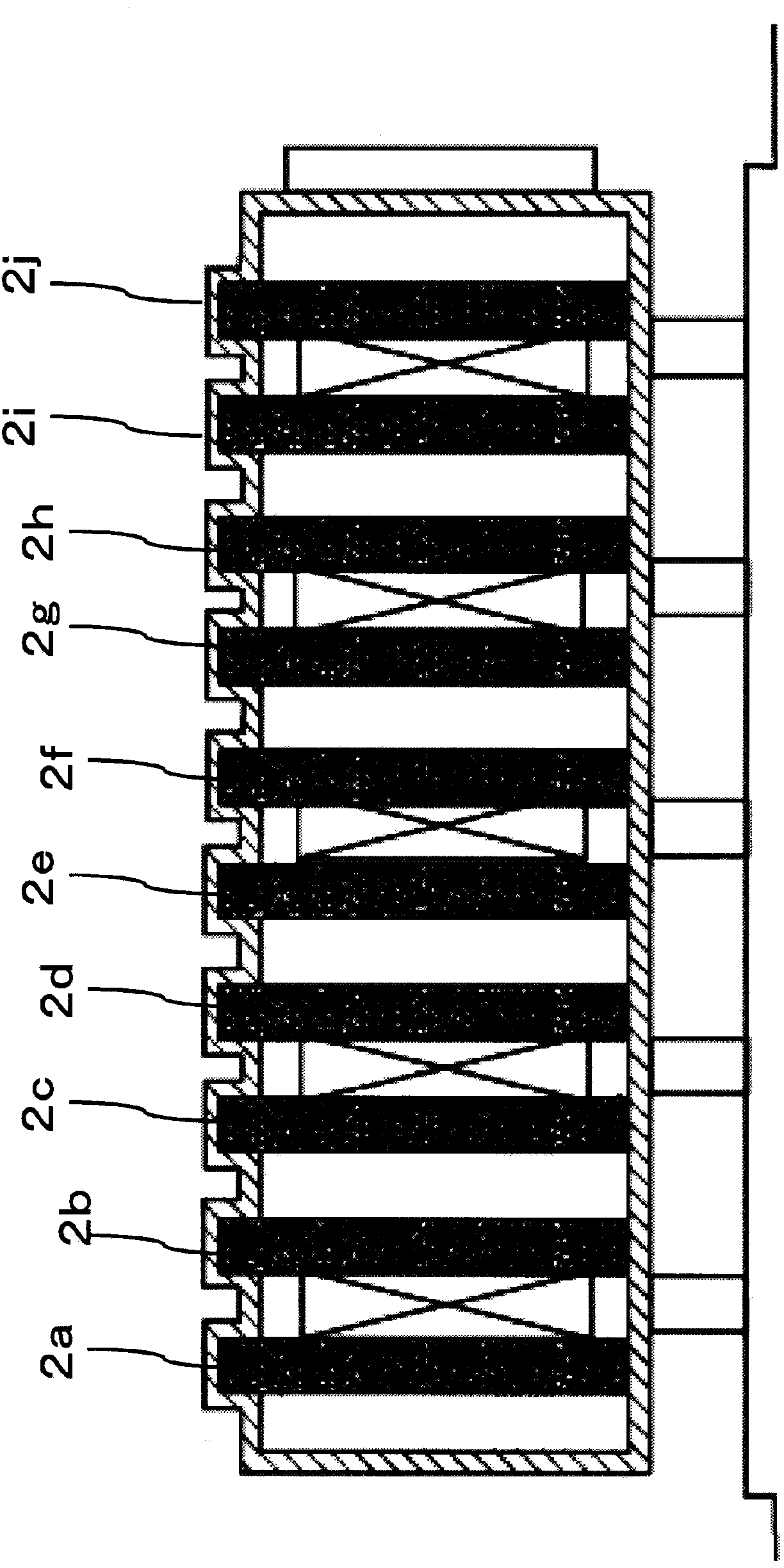

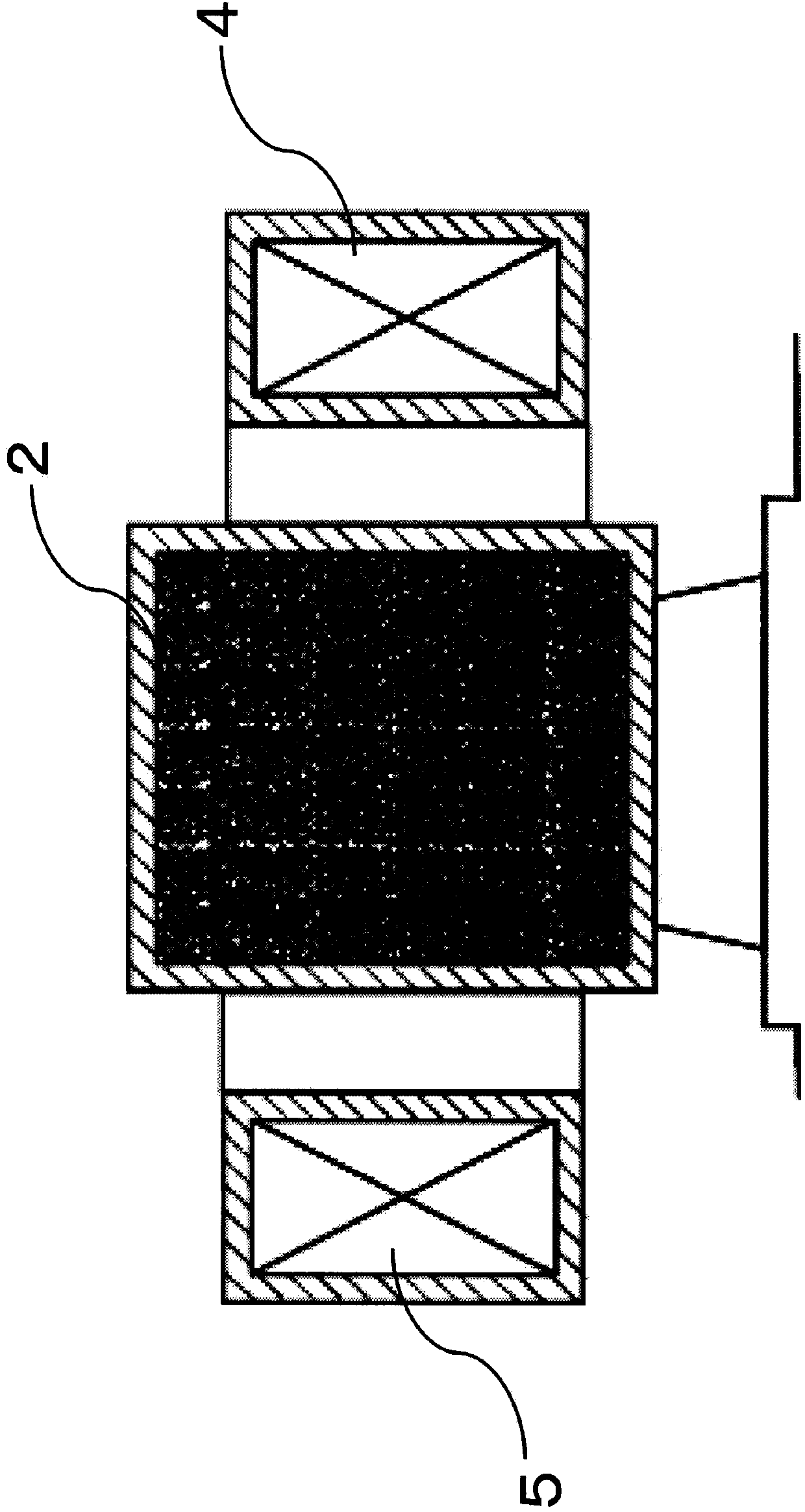

[0055] use figure 1 N shown 2 O removal device will implement N in waste gas of sewage sludge incinerator 2 The results of trial calculation of the amount of catalyst necessary for the O removal treatment are shown below. The N 2 O removal device has filled with each 4m 3 Catalysts have 10 layers of catalyst filled layers, with a total of 40m 3 catalyst.

[0056] The catalyst is the following iron-zeolite catalyst.

[0057] (catalyst type)

[0058] An iron-zeolite catalyst produced by the method described in Patent Document 1 was used. In addition, the iron-zeolite catalyst used in the test was produced according to the method described in Patent Document 1, and was in the form of pellets with a diameter of 2 mm x a length of 5 mm, and the zeolites were β-type and MFI-type.

[0059] (Catalyst Performance Evaluation)

[0060] The following formula is the space velocity A / Hr, exhaust gas temperature 450°C, and ammonia added to NH 3 / N 2 N under the condition that O m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com