The beneficiation method of tungsten-containing tin concentrate

A beneficiation method and concentrate technology are applied in the field of beneficiation of tungsten-tin concentrates, which can solve problems such as unstable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

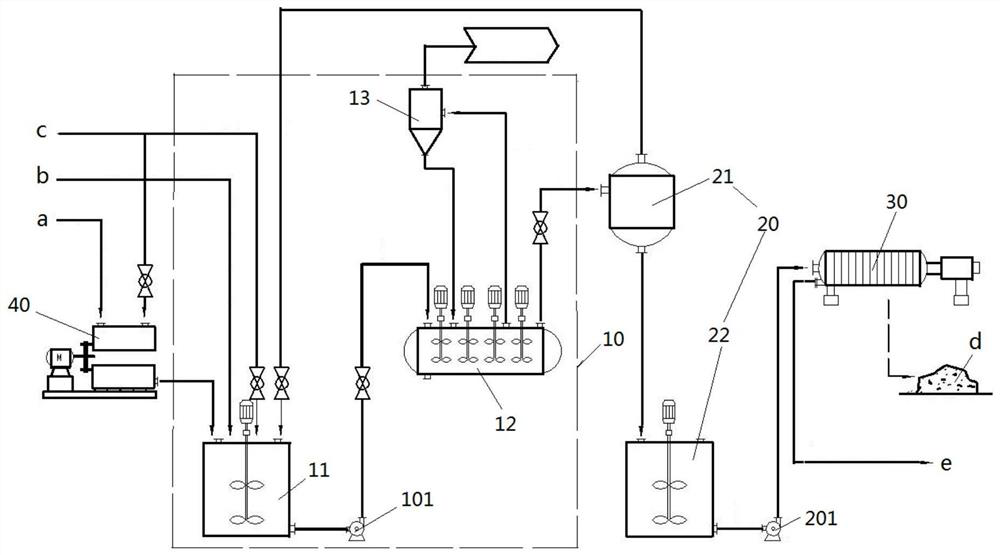

[0057] use as figure 1 The beneficiation device shown is for beneficiation of tungsten-containing tin concentrate. specifically:

[0058] The main components of the tungsten-containing tin concentrate are analyzed as follows:

[0059] element sn WO 3

Mo CaO Fe S P As SiO 2

MgO Contentwt% 34.75 9.54 0.40 14.92 6.39 0.33 0.04 0.68 1.89 0.25

[0060] Put the tungsten-containing tin concentrate into the ball mill at a speed of 500kg / h through a screw conveyor, and at the same time add industrial water to the ball mill at a speed of 250L / h for wet ball milling to make abrasives; Add sodium carbonate at a feed rate of 75kg / h, add industrial water at a rate of 75kg / h and mix under stirring;

[0061] The prepared slurry continuously enters the pressure leaching tank at a flow rate of 865kg / h, and the leaching reaction is carried out under the state of stirring and electric heating. During this period, the residence time of the...

Embodiment 2

[0065] use as figure 1 The beneficiation device shown is for beneficiation of tungsten-containing tin concentrate. specifically:

[0066] The specific elemental analysis of tungsten-containing tin concentrate is the same as in Example 1, and the treatment process is as follows:

[0067] Put the tungsten-containing tin concentrate into the ball mill at a speed of 500kg / h through a screw conveyor, and at the same time add industrial water to the ball mill at a speed of 1000L / h for wet ball milling to make abrasives; Add sodium carbonate at a feeding rate of 150kg / h, add industrial water at a rate of 150kg / h and mix under stirring;

[0068] The prepared slurry continuously enters the pressure leaching tank at a flow rate of 1950kg / h, and the leaching reaction is carried out under the state of stirring and electric heating. During this period, the residence time of the slurry in the pressure leaching tank was 4 hours, the leaching temperature was 220° C., and the leaching press...

Embodiment 3

[0072] use as figure 1 The beneficiation device shown is for beneficiation of tungsten-containing tin concentrate. specifically:

[0073] The specific elemental analysis of tungsten-containing tin concentrate is the same as in Example 1, and the treatment process is as follows:

[0074] Put the tungsten-containing tin concentrate into the mixing tank at a speed of 500kg / h through the screw conveyor, and at the same time add sodium carbonate at a feeding speed of 25kg / h, and add industrial water at a speed of 350kg / h to prepare the slurry under stirring;

[0075] The prepared slurry continuously enters the pressure leaching tank at a flow rate of 875kg / h, and the leaching reaction is carried out under the state of stirring and electric heating. During this period, the residence time of the slurry in the pressure leaching tank is 1 h, the leaching temperature is 160° C., and the leaching pressure is 0.6 MPa. During the leaching reaction, the generated non-condensable gas mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com