Opening reserving device for subway monolithic track bed concrete and construction method thereof

A technology of integrated ballast and reserved openings, applied in the field of engineering science, can solve the problems of concrete construction quality decline, slow construction progress, concrete moisture segregation, etc., and achieve the effect of simple and feasible combined structure, easy installation and disassembly, and reduced transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

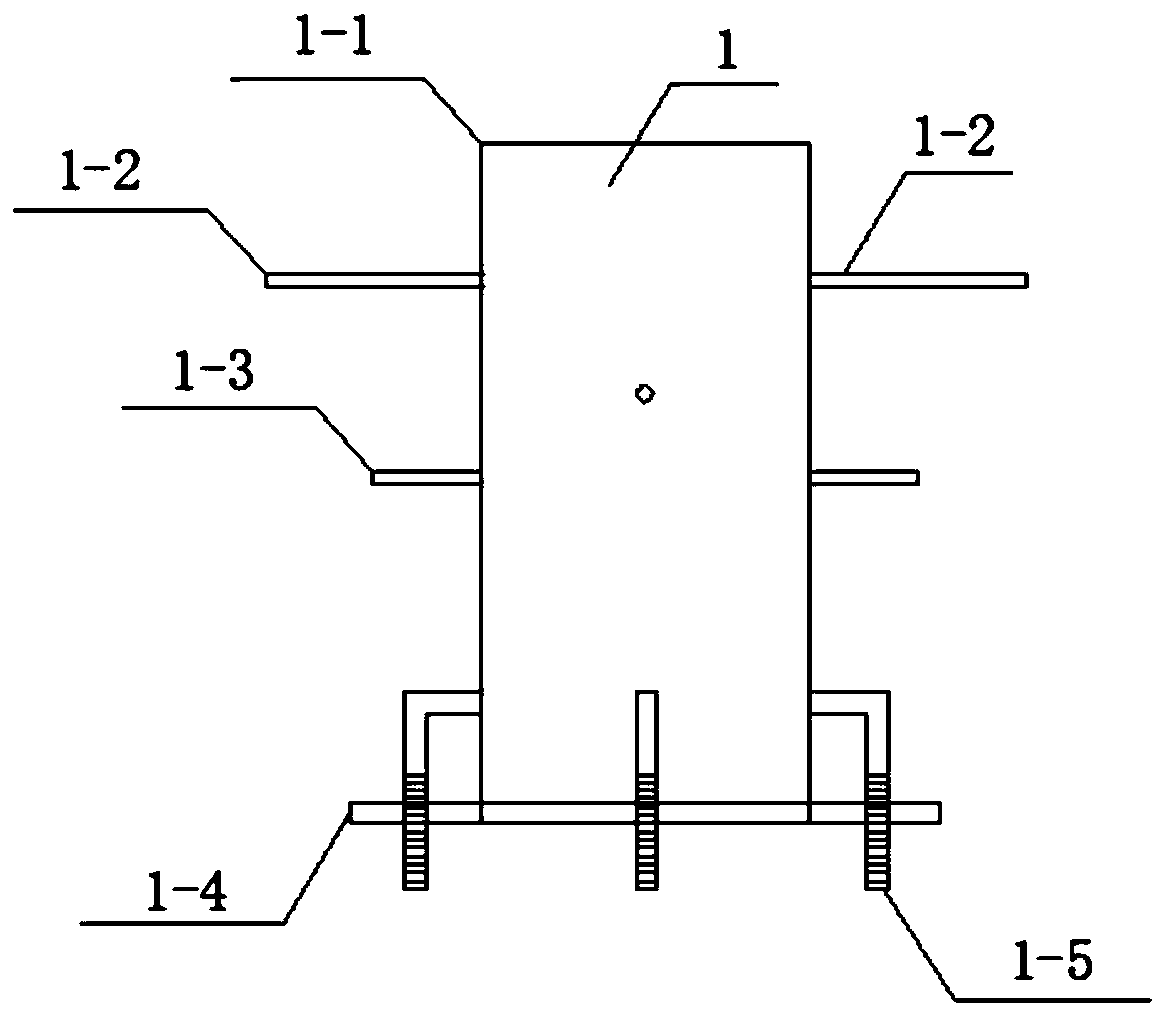

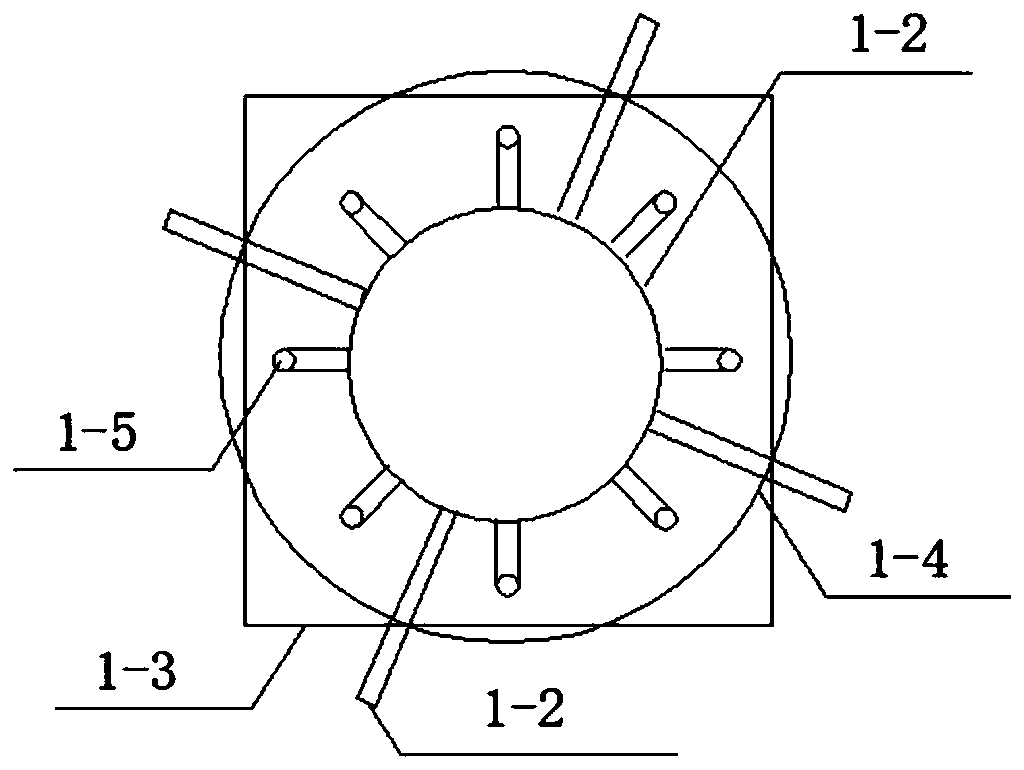

[0032] Refer to Fig. 1(a), Fig. 1(b), Fig. 1(c), Fig. 1(d), Fig. 1(e), Fig. 1(f), the concrete opening is reserved in the station shield well, and the When capping the end well, use φ300mm steel pipes to form reserved openings on the roof of the platform floor and the station hall floor respectively. The outer wall of the steel pipe is welded with φ14 steel bars, and at the same time, the steel bars extend into the structural concrete of the roof structure for no less than 200mm and are welded with the structural steel pipes. Weld the base steel plate at the bottom of the steel pipe, and at the same time pass the embedded bolt through the base steel plate and weld it to the steel pipe. Specifically, in this embodiment, the embedded bolt is composed of a horizontal section and a vertical section, and the horizontal section One end is connected with the steel pipe, the other end of the horizontal section is connected with the upper end of the vertical section, the lower end of t...

Embodiment 2

[0037] See Figure 2(a), Figure 2(b), Figure 2(c), Figure 2(d) and combine image 3 and Figure 4 , when not using the station end well to reserve the concrete opening, use a flange to fix and seal the top of the steel pipe at the top of the discharge channel to prevent rainwater from entering, and cover it with a concrete cover to ensure road traffic. When it is necessary to use the reserved opening, apply to the traffic control department for temporary occupation of the road for construction. Connect the first pre-embedded pipe structure on the station hall floor and the second pre-embedded pipe structure on the station hall floor with steel pipes of the same diameter, so as to connect them to the reserved opening on the ground, and reserve a certain length of steel pipes on the station hall floor to expose To the lower side of the top floor of the station so that the distance between the nozzle and the ash port of the tank truck connected to the underground line to the concr...

Embodiment 3

[0039] After the reserved opening is used up, the connecting steel pipe connecting the platform floor and the station hall floor is removed, and at the same time, a circular steel plate with a diameter of φ300mm is welded to the bottom of the pre-embedded steel pipe structure at the platform floor and the station hall roof, and the micro-expansion concrete Backfill the pre-embedded steel pipes, and install rubber waterstops and flanges at the bottom of the steel pipes through pre-embedded bolts, and set a waterproof protective layer on the top of the steel pipes by coating waterproof paint as a concrete protective layer. Finally, the structural surface and the road surface are chiseled. After chiseling, brush 2mm thick waterproof paint and lay linoleum to form a protective layer. The thickness of the protective layer is not less than 8cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com