Preparation method of corn hydroxy propyl distarch glyceride

A technology of hydroxypropyl digitrin glycerin and corn starch, which is applied in the field of preparation of modified starch, can solve problems such as backwardness and backward processing technology, and achieve the effects of wide source of raw materials, cost control, and easy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

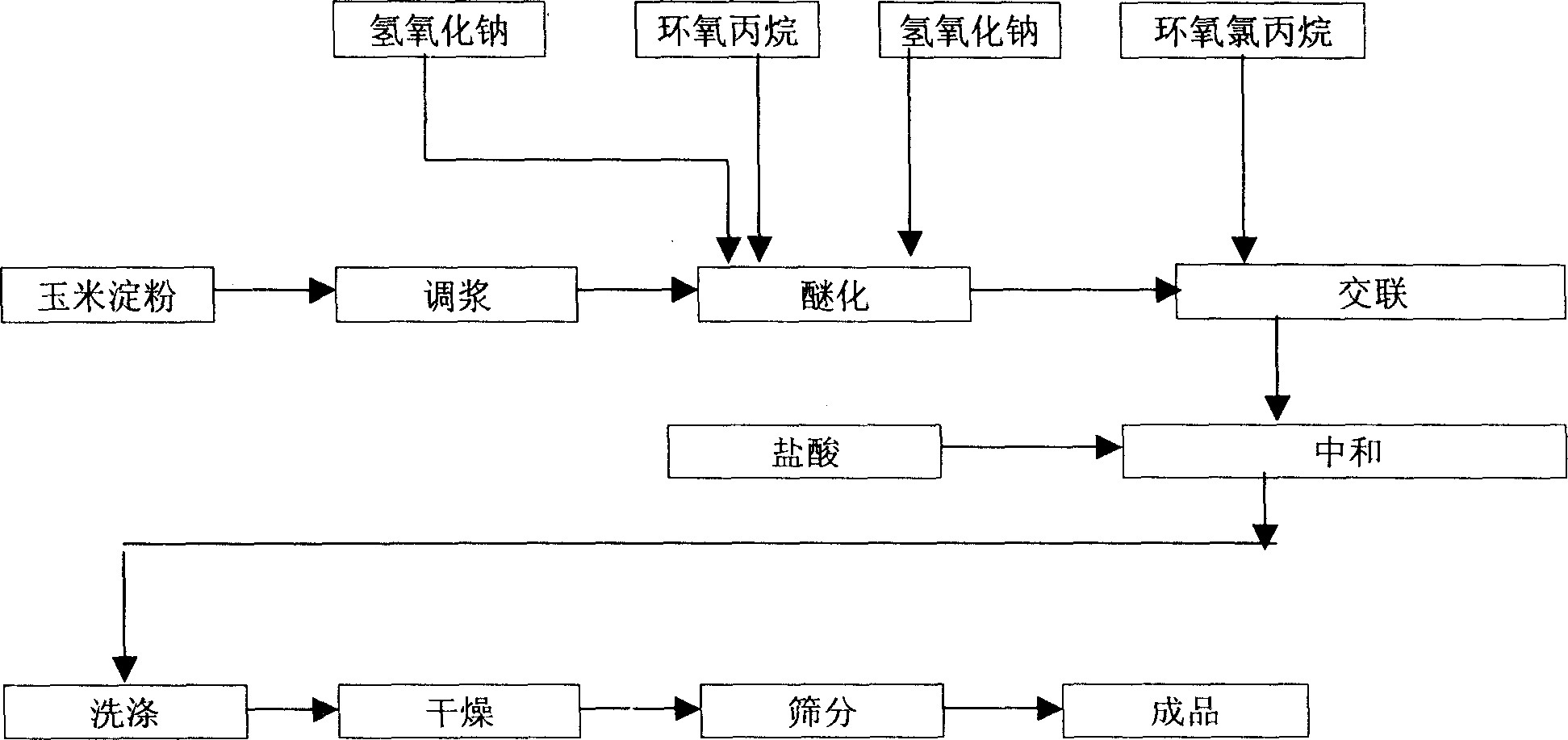

Method used

Image

Examples

Embodiment 1

[0021] First, add 100 kilograms of cornstarch and 10 kilograms of sodium sulfate to 180 kilograms of water in the reactor to adjust the starch slurry of 20-23Be, stir continuously, and add sodium hydroxide with a mass concentration of 3-3.8% in the kettle to adjust the pH value to 11.5, then add 6 kg of propylene oxide and heat up to 49°C for 14 hours. Add 10ml of epichlorohydrin to the above-mentioned etherified starch slurry, and continue to react for 19 hours. After the above-mentioned crosslinking reaction is completed, adjust the pH value to 6.0 with hydrochloric acid with a mass concentration of 9%, and add 200 kg of water to the kettle. Washing, sedimentation, and then washing and sedimentation in the same way to remove impurities (sodium sulfate, sodium chloride or other chemical residues) to obtain finished products.

Embodiment 2

[0023] The steps are the same as in Example 1, except that the pH value of the etherification reaction process is maintained at 11.0.

Embodiment 3

[0025] The steps are the same as in Example 1, except that the pH value of the etherification reaction process is maintained at 12.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com