Novel wheel type acting device

A working and wheeled technology, applied in stators, engine components, machines/engines, etc., can solve the problems of reducing volume and weight, low energy conversion efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

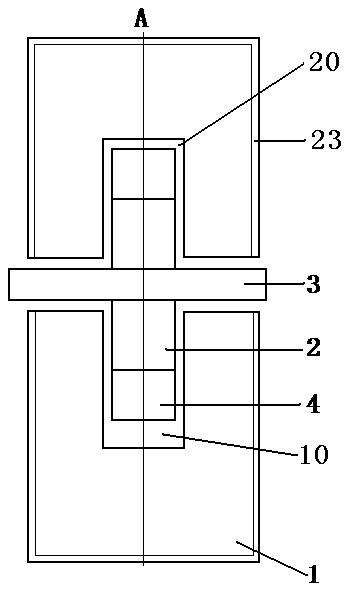

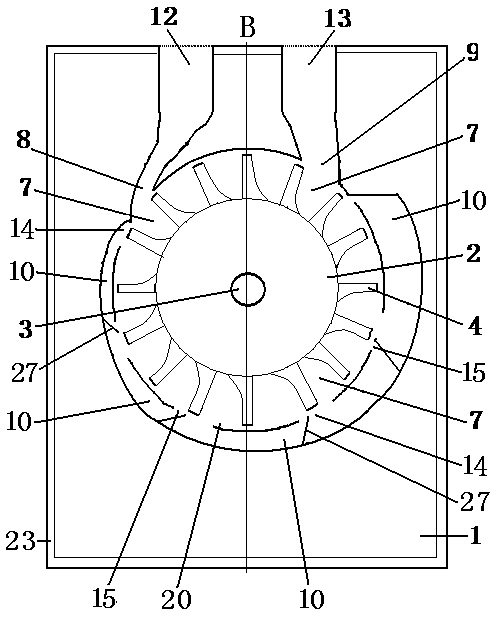

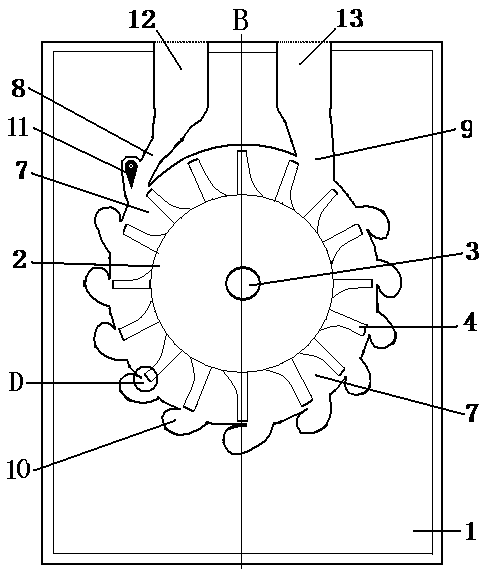

[0049] In order to more clearly illustrate the technical features of the new wheeled power device, the scheme will be further elaborated below through ten implementation modes combined with the accompanying drawings.

[0050]figure 1 , figure 2 Shown is the first embodiment of the new wheeled work device. It can be seen from the accompanying drawings that the new wheeled work device shown in this embodiment is mainly composed of a casing 1 and an impeller, and the casing 1 has a thermal insulation layer 23, the thermal insulation layer 23 has thermal insulation material, and the impeller is composed of a wheel body 2, an axle 3, and blades 4, and the blades 4 are installed on the outer circumference of the wheel body 2, and the center of the wheel body 2 is equipped with Axle 3, the impeller is installed in the impeller wheel chamber 20 in the housing 1, the size of the impeller wheel chamber 20 matches the impeller, the impeller and the inner wall of the wheel chamber 20 mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com