A stepped oblique flow spiral baffle heat exchanger

A technology of helical baffles and baffles, applied in indirect heat exchangers, heat exchanger types, heat exchanger shells, etc. Difficulty in processing and assembling, to achieve the effect of reducing the burst rate, enhancing the stability, and enhancing the heat transfer coefficient of the shell side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

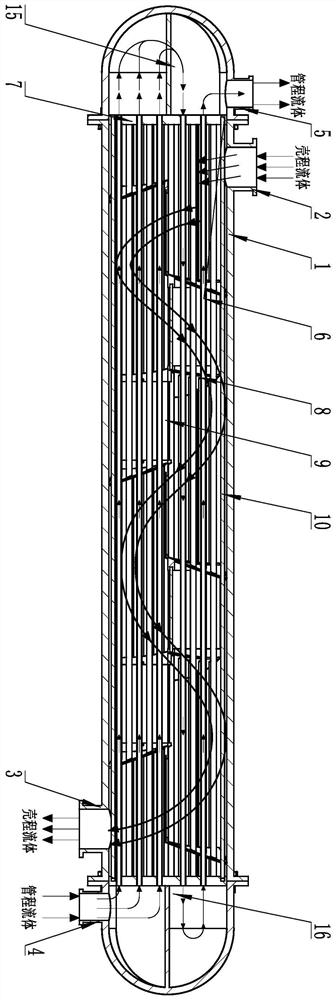

Embodiment 1

[0054] according to Figure 1 to Figure 7 and Figure 10 to Figure 15 A stepped oblique flow spiral baffle heat exchanger is shown, which includes a shell 1 and a head. The shell 1 is provided with a shell-side fluid inlet connection 2 and a shell-side fluid outlet connection 3. The A pipe-side fluid inlet connection pipe 4 and a pipe-side fluid outlet connection pipe 5 are arranged on the head of the pipe side, and several heat exchange tubes 6 are longitudinally arranged in the housing 1, and the two ends of the heat exchange pipes 6 pass through the The tube sheet 7 at the port of the housing 1 communicates with the head, and it is characterized in that, the housing 1 is provided with several sets of helical periodic baffle groups, and each group of the helical periodic baffles The plate group includes several oblique flow curved baffles 8 arranged in the spiral circumferential direction and with different phases. The oblique flow curved baffles 8 form a certain inclinatio...

Embodiment 2

[0059] Such as Figure 10 to Figure 16 and Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that: each group of the spiral periodic baffles includes three oblique flow curved surface baffles 8, and the oblique flow curved surface baffles The axial projection of the plate 8 is fan-shaped and the fan-shaped angle is 120°. The oblique flow curved baffle 8 in the housing 1 is composed of three sets of oblique flow curved baffles 8. .

[0060] Compared with Embodiment 1, this embodiment makes further limitations on the oblique flow curved baffle 8 .

Embodiment 3

[0062] Such as Figure 10 and Figure 21 As shown, the difference between this embodiment and Embodiment 1 is that: the end of the oblique flow curved baffle 8 and the baffle 9 protrudes toward the side of the baffle 9 with a block 11. The block 11 is provided with a slot 12 that is compatible with the baffle 9, and the baffle 9 and the block 11 are both horizontally coaxially provided with equal-diameter pins A hole 13, the pin hole 13 is provided with a cylindrical pin 14 adapted to the pin hole 13.

[0063] Compared with Embodiment 1, this embodiment further limits the curved baffles 8 for oblique flow. When assembling, firstly insert the curved baffles 8 for oblique flow into the slots 12 one by one, and then insert the cylindrical pins 14. Several sets of helical periodic baffles are formed in the pins, and then the heat exchange tubes 6 and the tie rods 10 are inserted in sequence, and then the whole is inserted into the shell 1, and the tube sheets 7 are sealed at bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com