Three-dimensional cycloid-like intelligent polishing method guided by Hilbert curve

A curve-guided, pendulum-like technology, applied in the field of mechanical processing, can solve the problems of unstable polishing quality, low processing efficiency, complex parameter relationship, etc., and achieve the effect of ensuring polishing uniformity, increasing multi-directionality, and improving surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

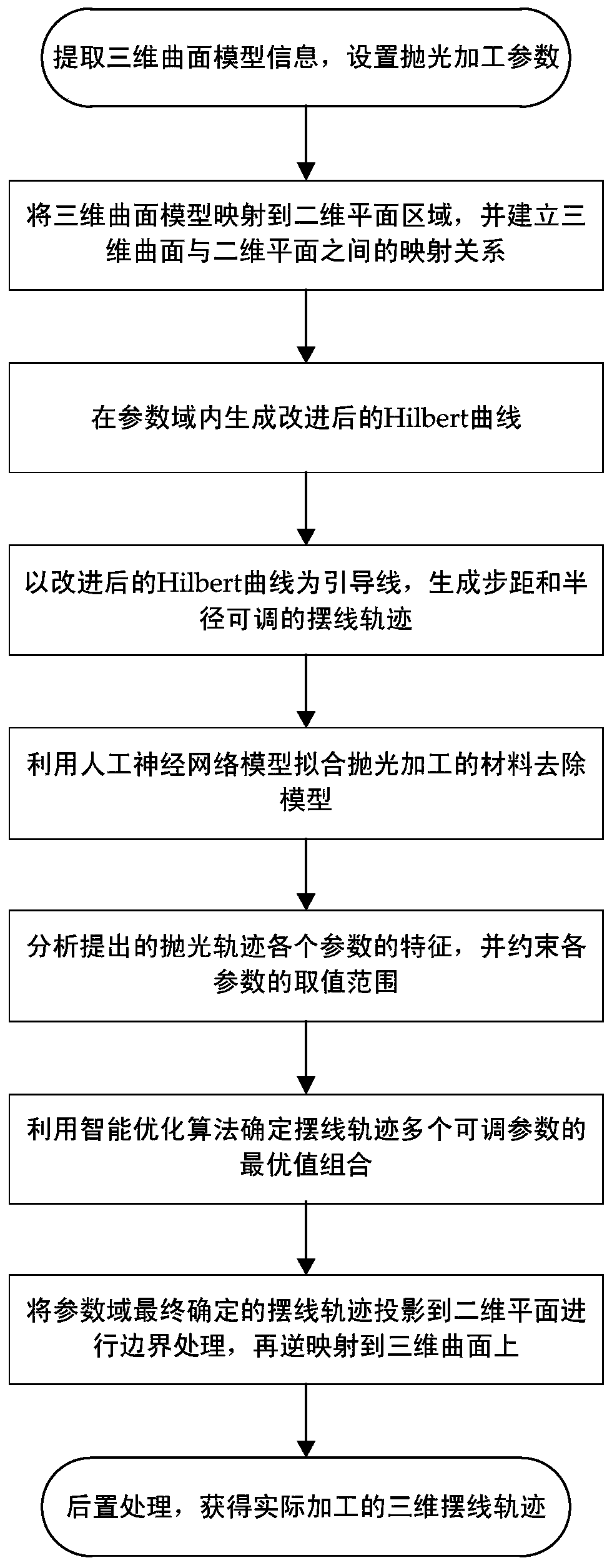

[0054] This embodiment provides a three-dimensional cycloid-like intelligent polishing method guided by a Hilbert curve. The flow chart is as follows figure 1 shown, including the following steps:

[0055] Step 1. Obtain the 3D grid model information of the workpiece, transform the mapping of the 3D grid surface into a 2D grid plane, and establish the spatial mapping relationship between the 3D grid surface and the 2D grid plane. The spatial mapping relationship between the grid surface and the 2D grid plane refers to: flatten the 3D grid surface model into a 2D grid plane model in the parameter domain, and establish the 3D grid surface model and the 2D grid plane model The one-to-one correspondence between the coordinates of each vertex is used to obtain the spatial mapping relationship between the three-dimensional mesh surface model and the two-dimensional mesh plane model.

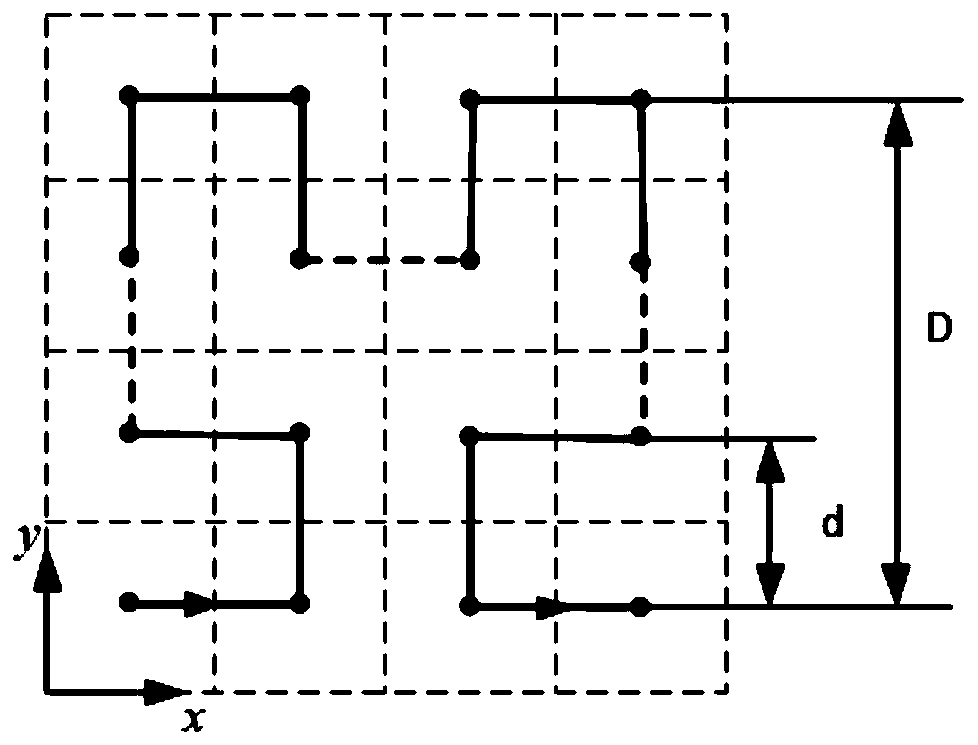

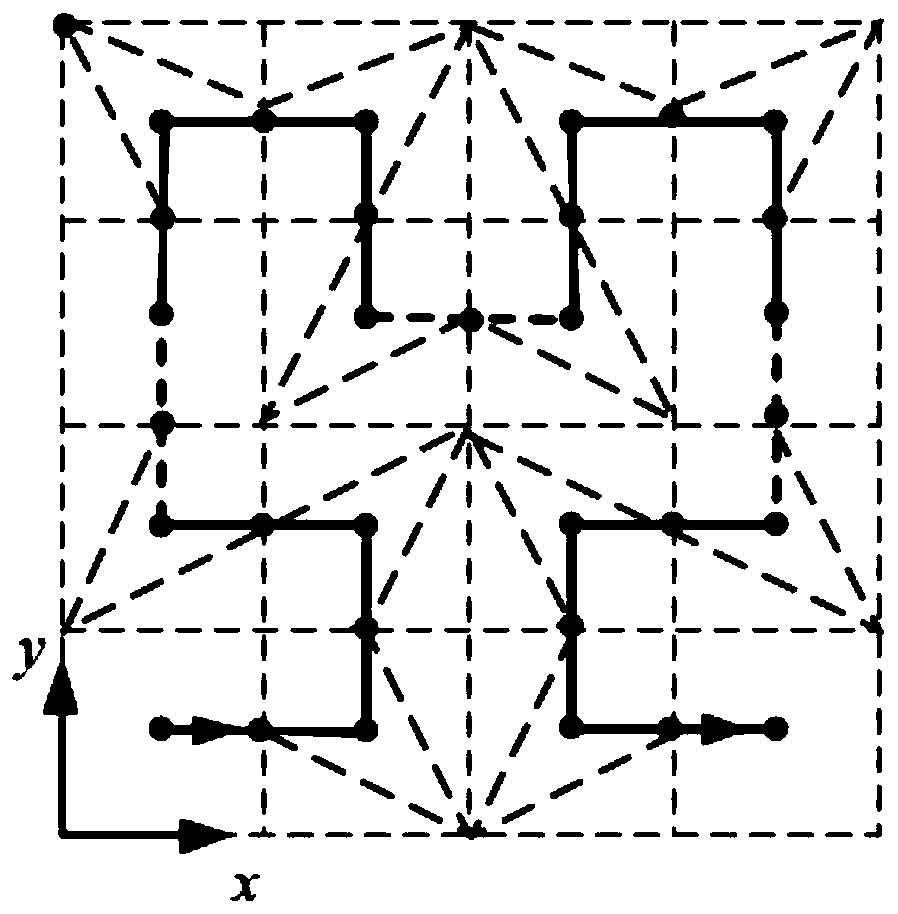

[0056] Step 2, generate a standard Hilbert curve in the two-dimensional parameter domain, and carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com