Assembly tooling and assembly method for series magnetic pole boxes of large-scale motor rotor

A large-scale motor and assembly tooling technology, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve the problems of strong magnetic pole box repulsion, difficult assembly, large size of permanent magnets, etc., to prevent magnetization , High production efficiency, economical processing and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

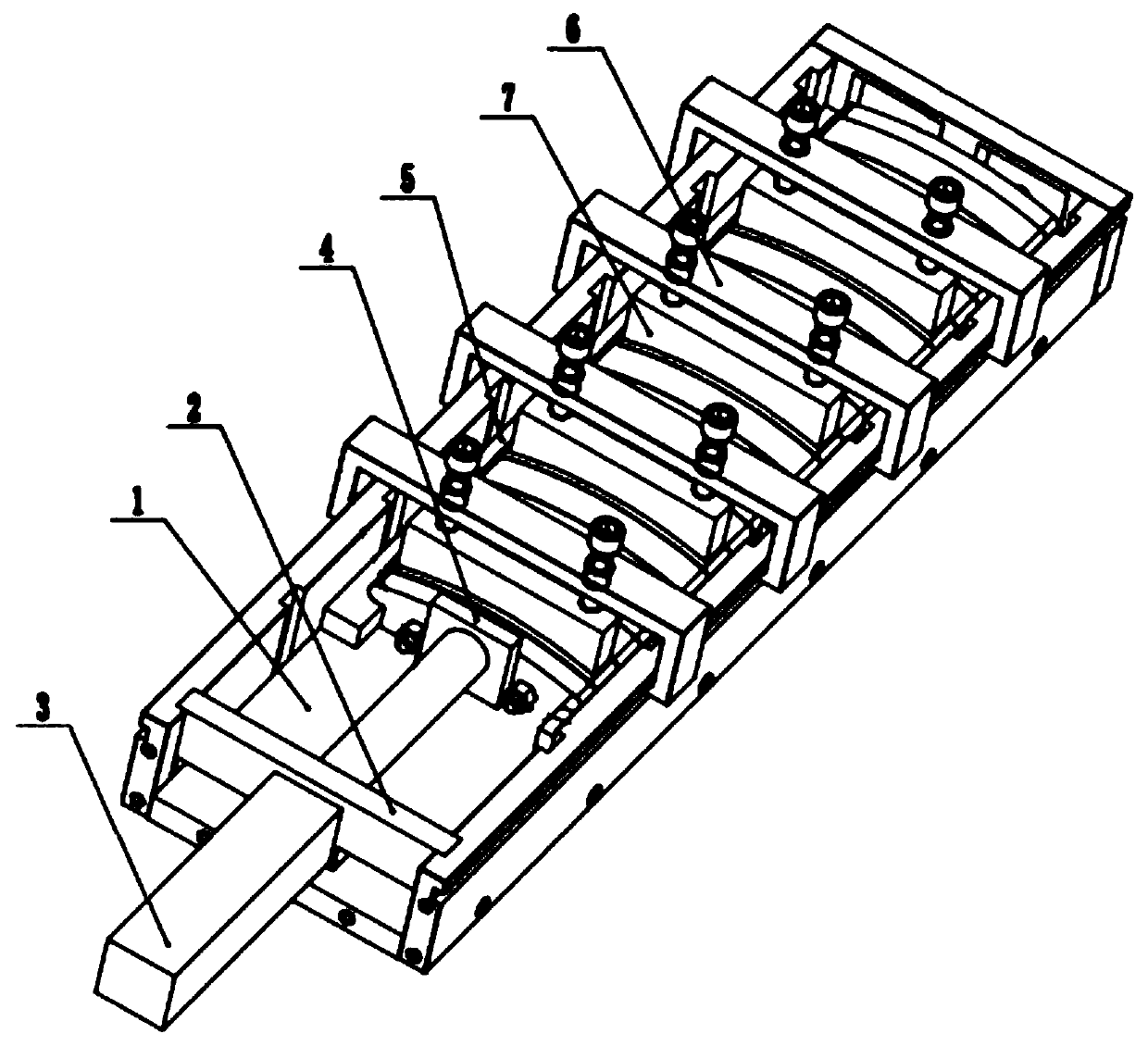

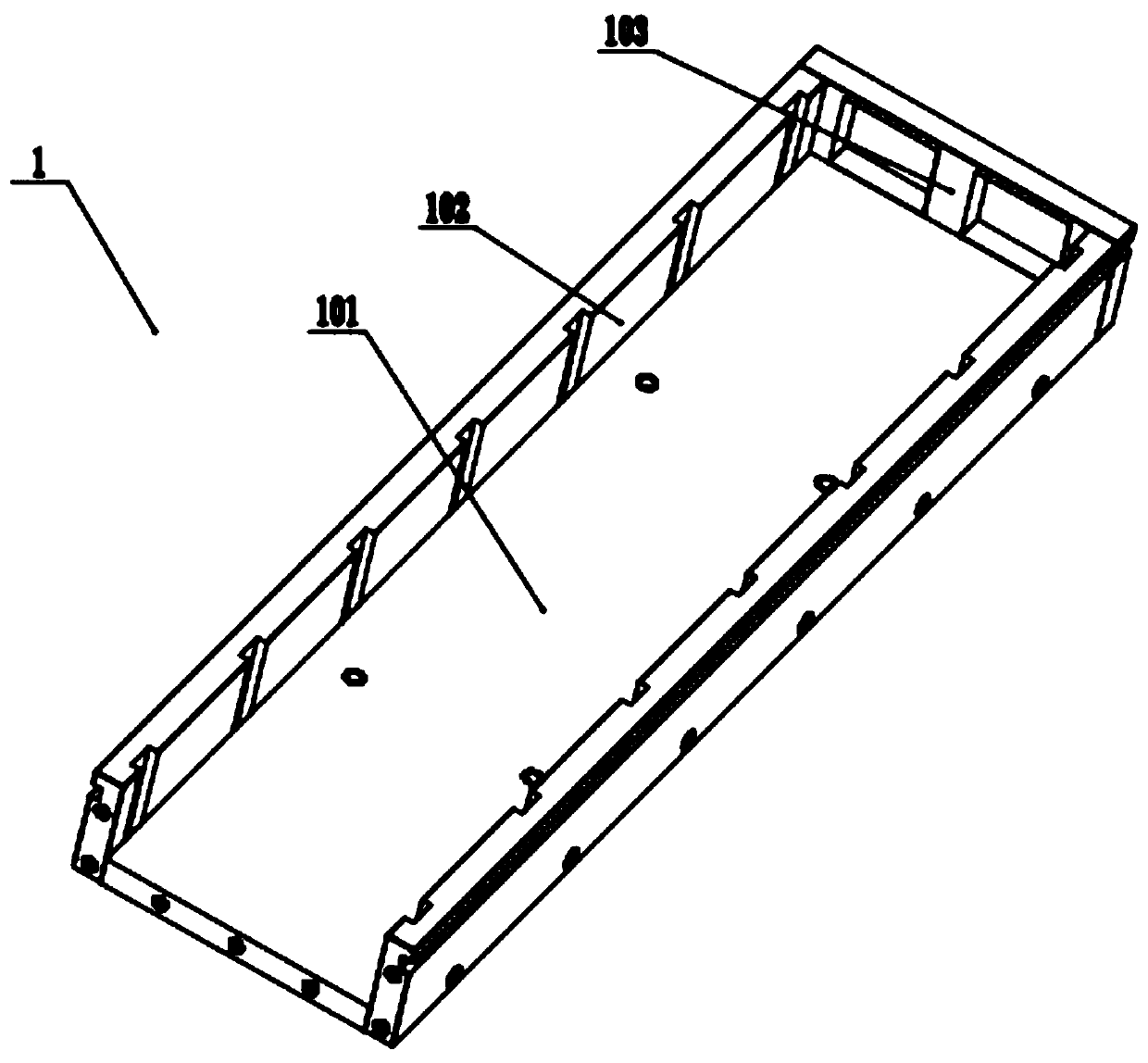

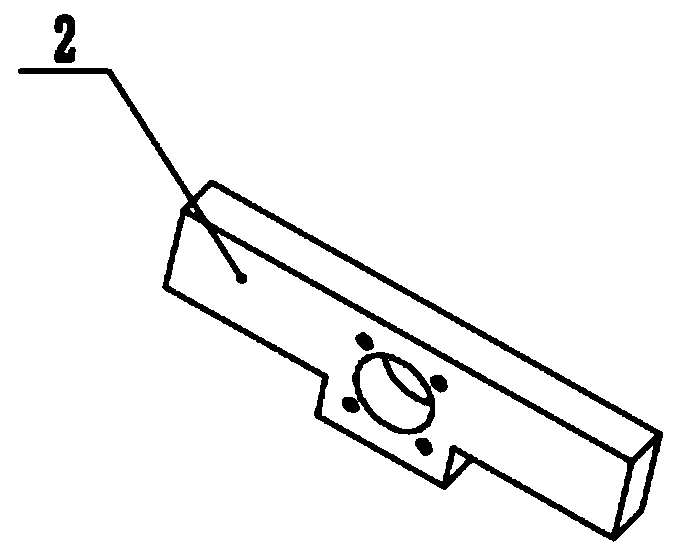

[0044] Such as Figure 1-Figure 6 As shown, the assembly tooling of the stringed magnetic pole boxes of the present embodiment includes a tooling base 1, an oil cylinder mounting plate 2, an oil cylinder 3, a push plate 4, a guide plate 5, a pressing tool 6, and a pressing plate 7, wherein the deoiling cylinder 3 In addition, the above structural materials are all made of non-magnetic materials. Specifically, the tool base 1, the oil cylinder mounting plate 2, the piston rod of the oil cylinder 3, the guide plate 5, the pressing tool 6 and the pressing plate 7 are all made of 316L stainless steel , The push plate 4 is made of brass, and all the fasteners in the present invention are also made of stainless steel. The material description in the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com