On-line dynamic balance adjustment system based on temperature-controlled shape memory alloy and control method thereof

A technology of memory alloy and adjustment system, which is applied in the direction of controlling mechanical energy, centering/balancing rotors, electric components, etc. It can solve problems that cannot be solved by off-line balance, nonlinear enhancement, and long balance time, and achieve good state maintenance effects. High-precision dynamic balance correction to ensure the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

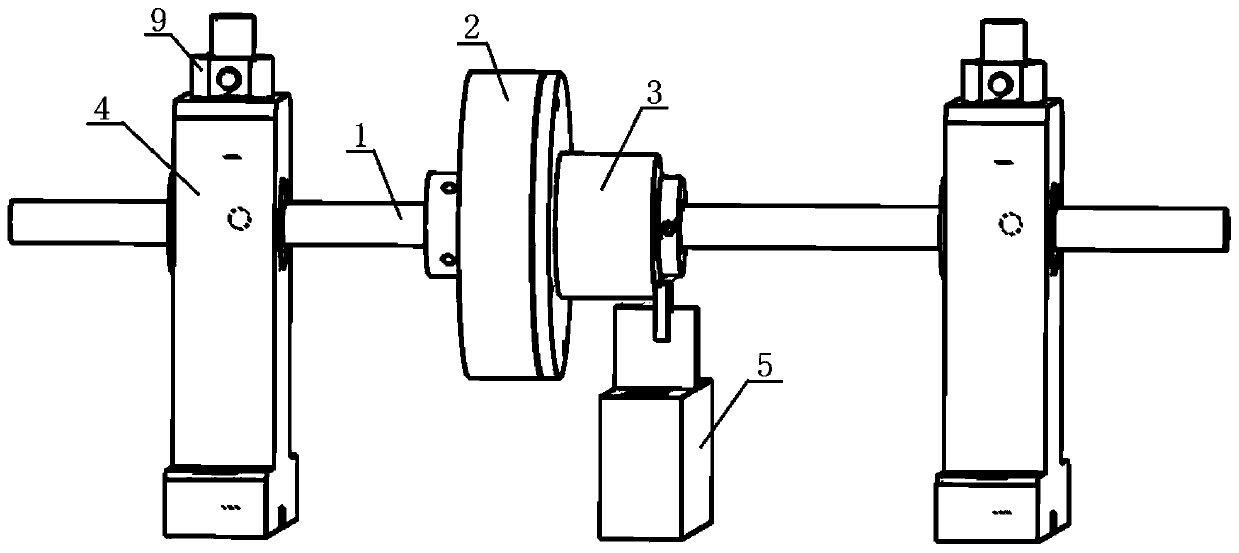

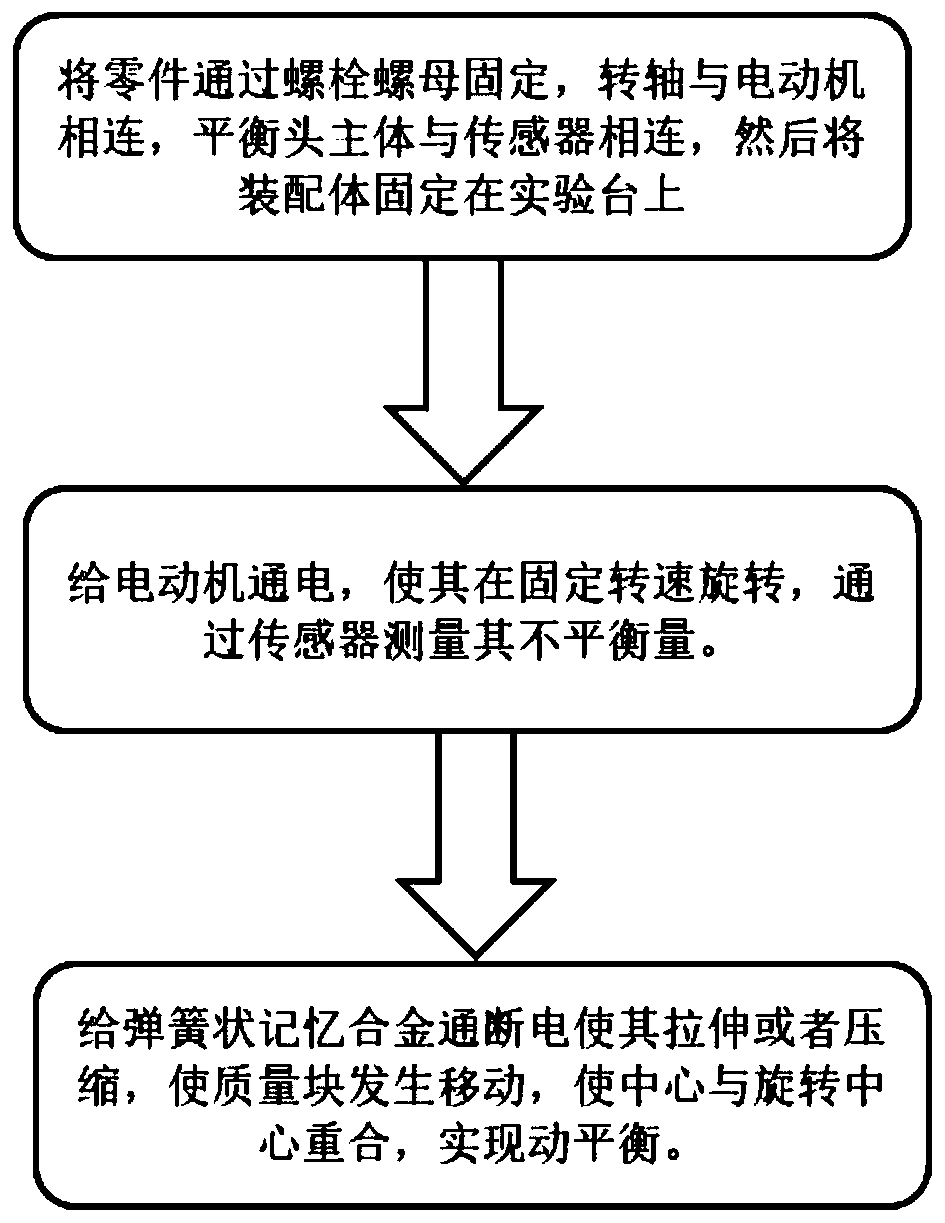

[0051] see Figure 1-Figure 7 Embodiments of the present invention provide an efficient and high-precision online dynamic balance adjustment system and method based on temperature-controlled shape memory alloys.

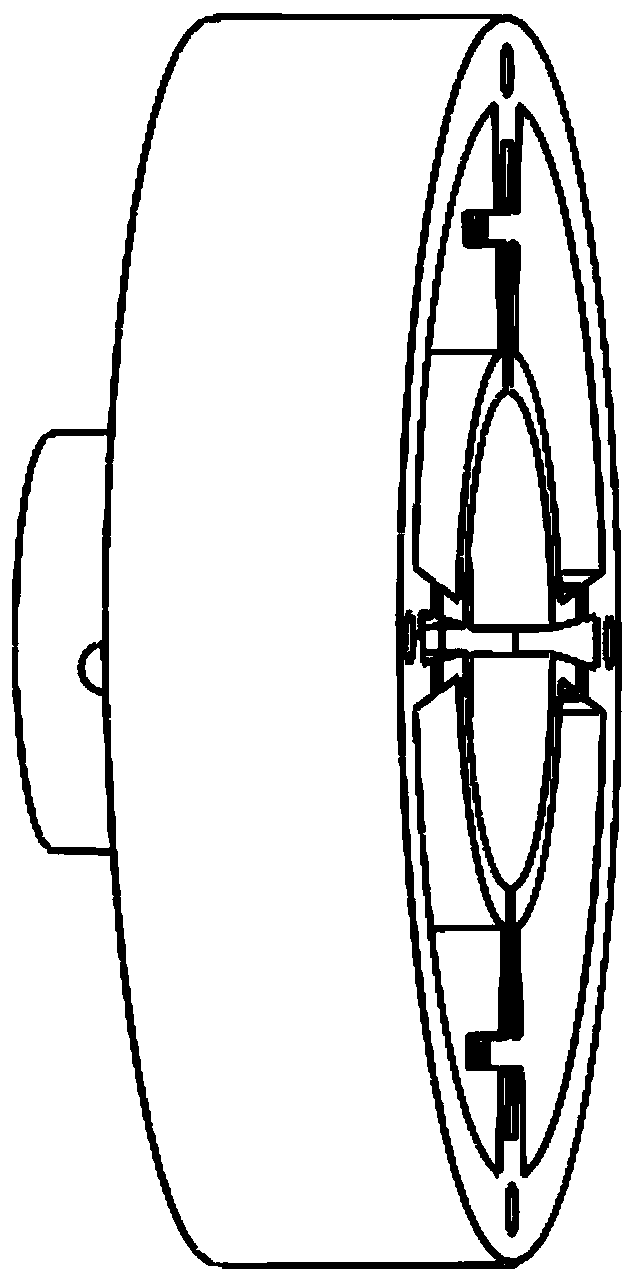

[0052] The online dynamic balance adjustment system based on temperature-controlled shape memory alloy of the present invention includes a balance head main body 2, the balance head main body 2 includes a housing 2-1, and the rotating shaft 1 passes through a through hole 2-1- opened in the center of the housing. 1 and is fixedly connected with the housing 2-1, and the housing 2-1 is provided with four mass blocks 6 around the through hole 2-1-1, wherein the middle of each mass block 6 is provided with an arc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com