Bone conduction earphone

A technology of bone conduction earphones and amorphous alloys, which is applied in the direction of bone conduction transducer hearing equipment, earpiece/earphone accessories, sensors, etc., which can solve the problems of high weight of bone conduction earphones, unsatisfactory sound quality conduction, and poor overall performance. Iron and steel materials and other issues, to achieve the effect of energy saving, low elastic modulus, good sound quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

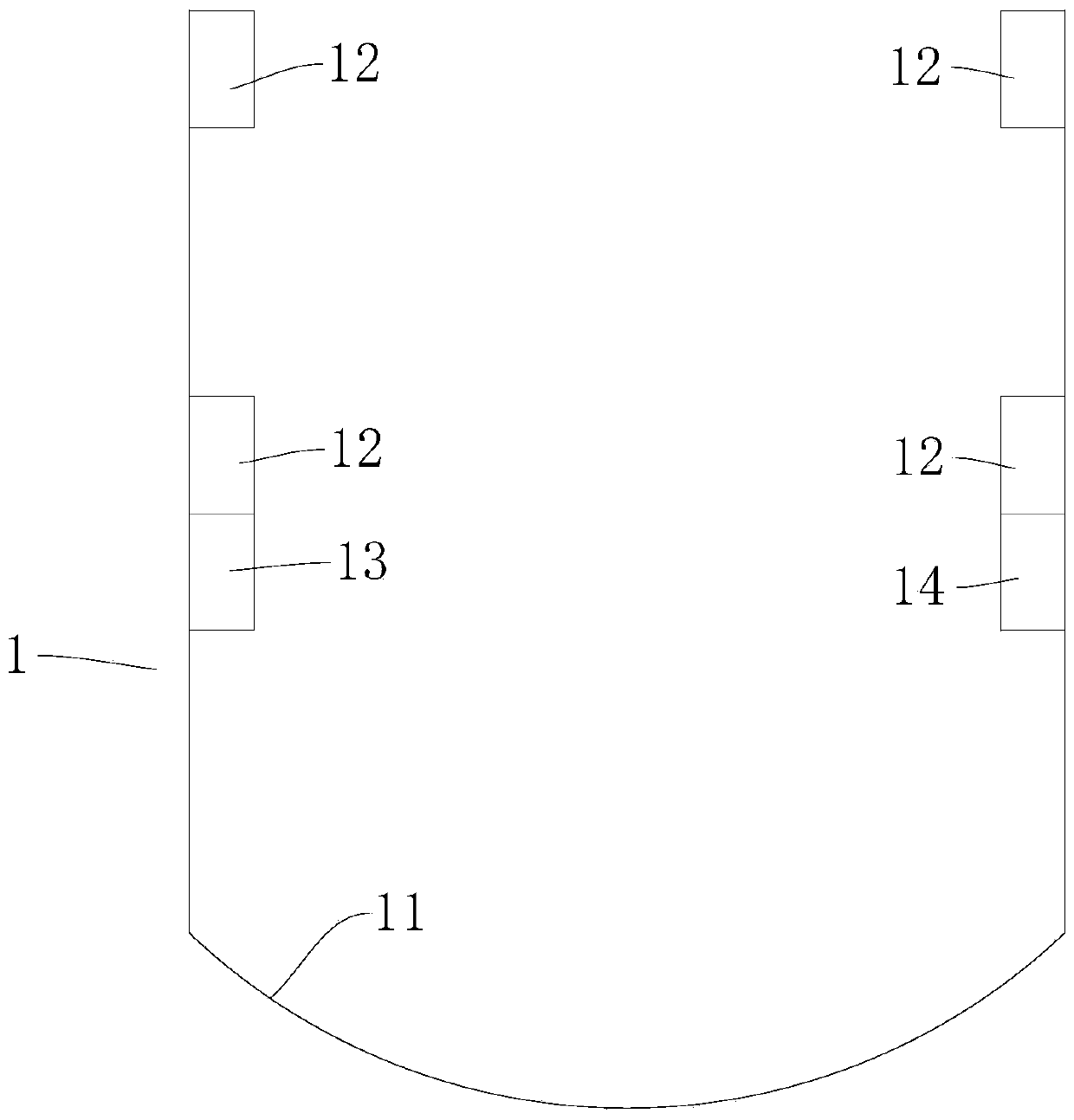

[0037] see figure 1 , shows a schematic structural view of a bone conduction earphone 1 according to a preferred embodiment of the present invention, the bone conduction earphone 1 includes a sounding device 12, a battery 13, a control motor 14, and a connecting piece 11 for connecting the above devices, The connector 11 is as figure 1 As shown in the approximately U-shaped skeleton structure, the components of the bone conduction earphone 1 contain several metal material components, and all or part of the metal material components in the bone conduction earphone 1 are amorphous alloys. As a preferred embodiment, the sound At least a part or all of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com