Bone conduction device

A bone conduction and bone conduction vibrator technology, which is applied to bone conduction transducer hearing equipment, sensors, sensor parts, etc., can solve the problems of unsatisfactory sound quality conduction, increase processing costs, and cannot stand a foothold, and reduce battery life. The capacity and weight of the control motor, the effect of perfect sound quality, high elastic limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

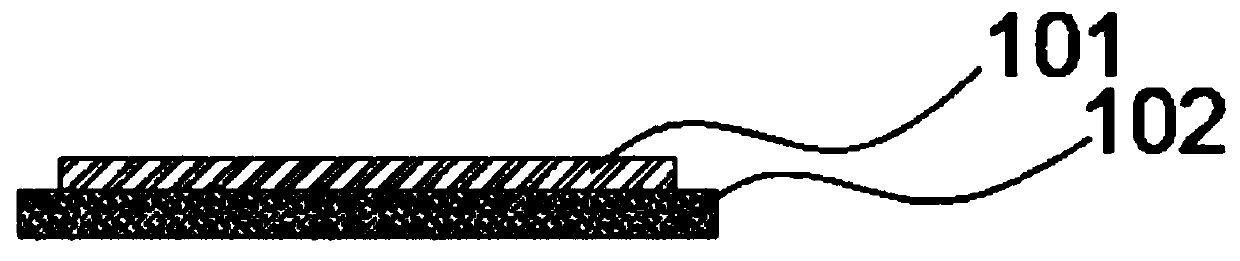

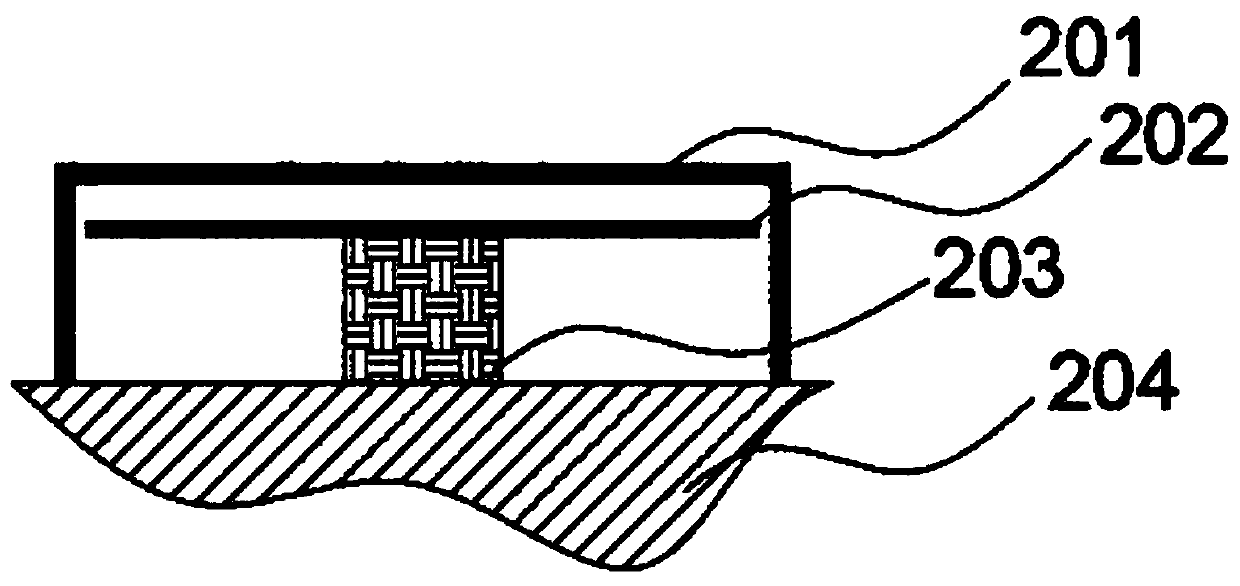

[0039] Embodiment 1 Piezoelectric bone conduction device

[0040] Piezoelectric bone conduction device is a device that uses the inverse piezoelectric effect of piezoelectric ceramics to conduct sound transmission. The piezoelectric vibrator is directly driven by an electrical signal with audio frequency, and vibration is generated through the mechanical deformation of the piezoelectric vibrator. The vibration is transmitted to the human body through the skull. The cochlea to perceive sound. The piezoelectric vibrator is the most important core structure in the piezoelectric bone conduction device. The bone conduction device using the piezoelectric vibrator generally has a resonance frequency of 1KHz or higher, so the occurrence of the low frequency region of the piezoelectric bone conduction device is easy. Insufficient reproduction, how to fully conduct conduction in the low-frequency region is the research focus of piezoelectric bone conduction devices.

[0041] Piezoelect...

Embodiment 2

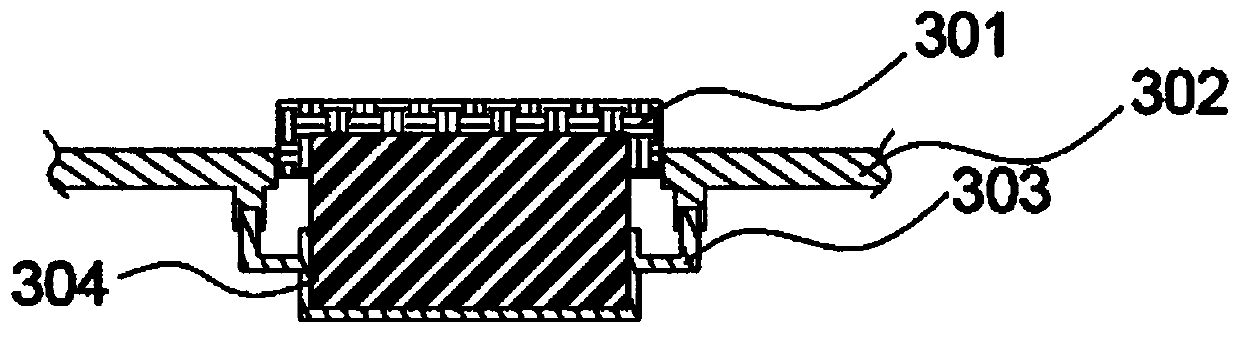

[0045] Embodiment 2 Electromagnetic bone conduction device

[0046] The principle of the electromagnetic bone conduction device is similar to that of the piezoelectric type, except that the bone conduction vibrator is a composite structure of magnets.

[0047] as attached image 3 Shown is a schematic diagram of the simple structure of the electromagnetic bone conduction device. The bone conduction device mainly includes a bone conduction vibrator 304, a fixed structure 302 arranged on both sides of the bone conduction vibrator, a protective front shell 301, and a protective rear shell 303, wherein any one of the protective front and rear shells can be used as a conduction conductor at the junction with the human body. The material is the same as the conduction column 203 in Embodiment 1.

[0048] The above-mentioned structures can all be made of amorphous alloy materials or partially made of amorphous alloy materials, and some of them are made of amorphous alloy materials, ...

Embodiment 3

[0051] In a piezoelectric bone conduction device or an electromagnetic bone conduction device, one or more of its internal or external skeleton structure, external shell structure or connection structure is made of amorphous alloy or partially made of amorphous alloy, For example, the connection part in the middle of the rear-mounted bone conduction earphone (overall structure), the outer shell and the inner shell that protect the sound transmission components on both sides, etc., in these components that are only used as structural parts, the proportion of amorphous alloys in terms of volume, Greater than or equal to 10% of the overall metal material component can meet the demand, and the proportion of amorphous state can be increased according to the use requirements, up to 90% (excessively high amorphous content puts higher demands on the amorphous alloy manufacturing process requirements, and the cost of preparation soars). The thickness of metal material components made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com