Ultrasonic-assisted laser device for preparing hydrophobic metal surface

An ultrasonic-assisted, laser device technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of the change of the hydrophobicity of the metal surface, the poor surface processing quality of the workpiece, and the small processing range, so as to improve the electro-acoustic performance. Conversion efficiency, anti-friction treatment, and calorific reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

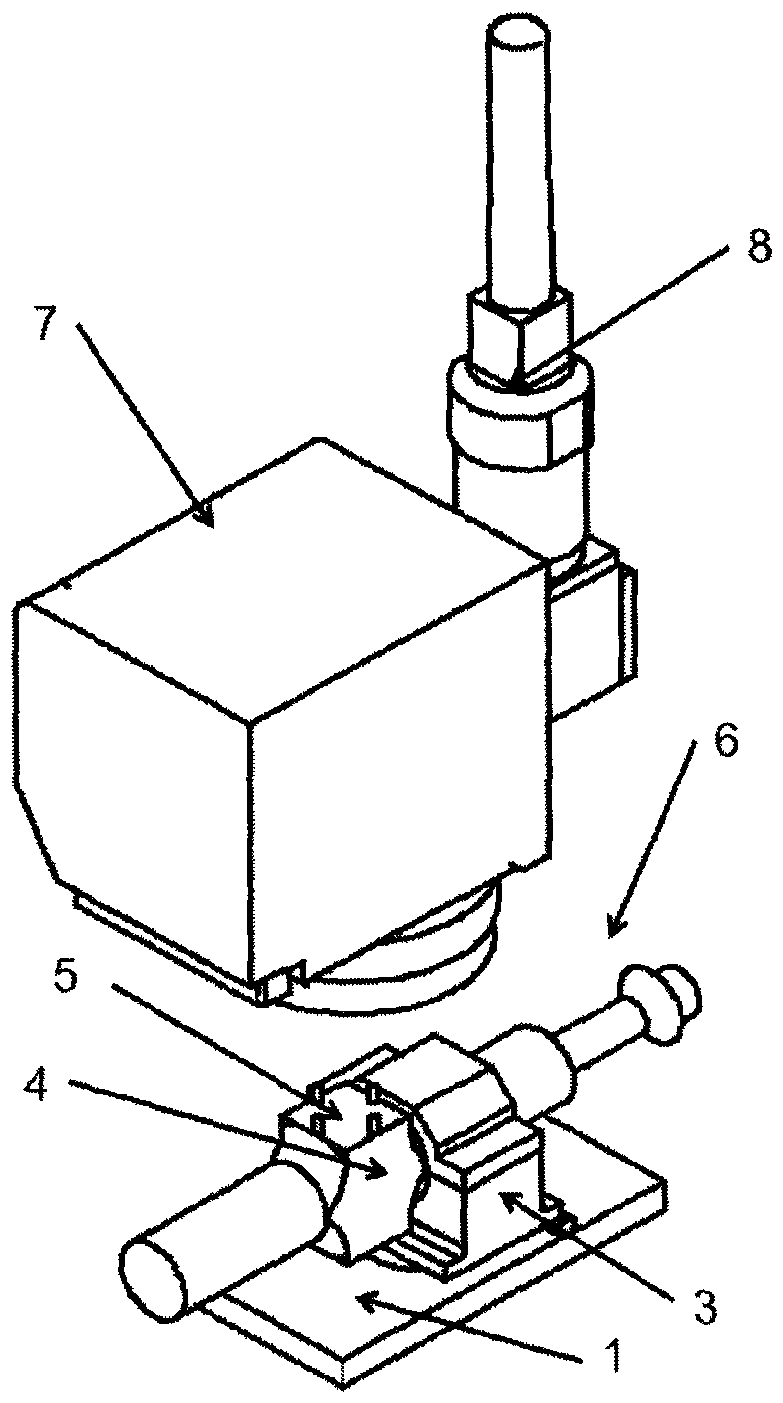

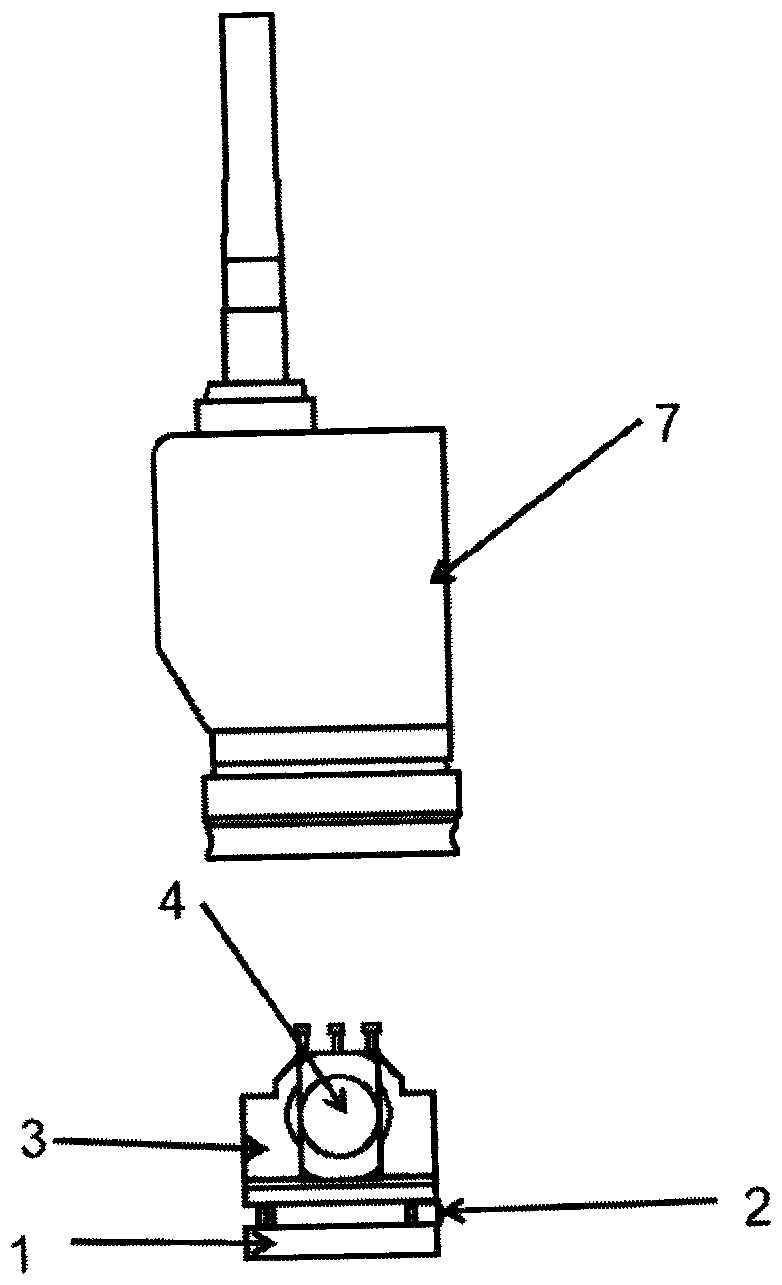

[0029] The ultrasonic-assisted laser device realizes the adjustment of the horizontal rotation angle of the ultrasonic vibrating table, such as figure 1 As shown, a rotating device 2 is installed between the upper surface of the bottom plate 1 and the clamping seat 3, a shock absorbing ring is installed inside the clamping seat, and an ultrasonic vibration device is installed. By adjusting the rotating device, the angular relationship between the ultrasonic vibration direction and the laser scanning direction can be changed to meet the requirements of different angles. The angle adjustment range of the rotating device is 180°, the adjustment accuracy is 0.1°, and it can realize self-locking at any position.

Embodiment 2

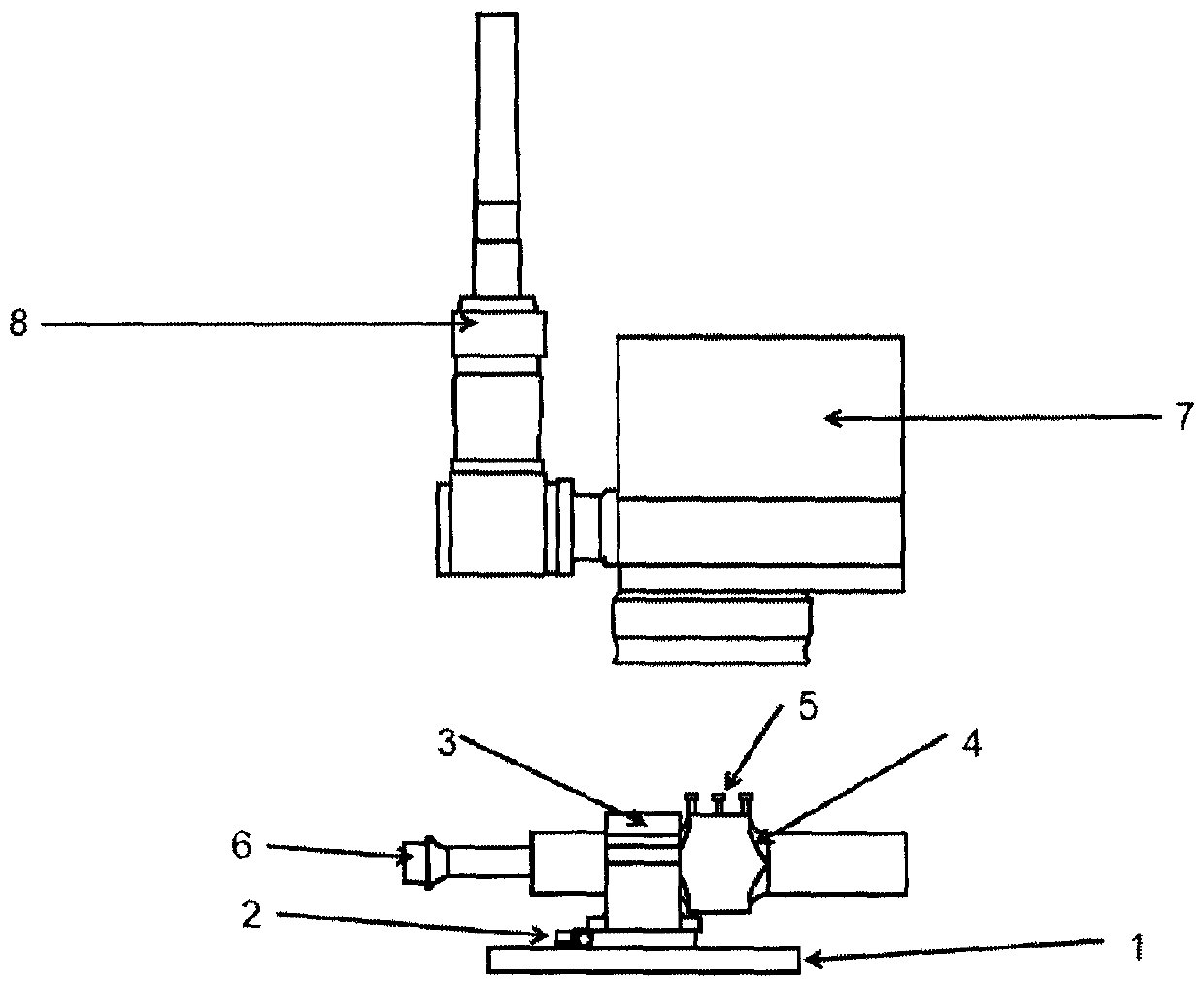

[0031] The ultrasonic-assisted laser device realizes the vertical position adjustment of the laser, such as figure 2 As shown, the laser is placed on the working surface of the ultrasonic vibration table. The characteristics of this structure are: the laser adjustment device 8 can be adjusted to change the vertical distance between the laser and the ultrasonic vibration table to realize the vertical movement of the laser. Thereby changing the size of the laser spot. The laser can realize self-locking when moving vertically, and the moving distance can be accurate to 0.1mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com