Bridge bent cap segmented prefabricating, splicing and fixing method

A technology of segmented prefabrication and fixing method, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as unbalance, achieve the effect of easy operation, speed up construction progress, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

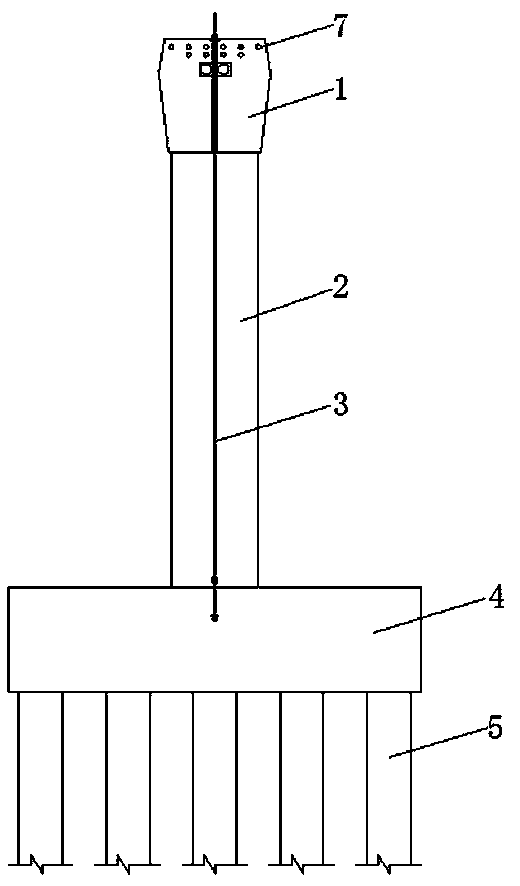

[0022] Embodiment: The segmental prefabricated assembly and fixing method of the bridge cover beam in this embodiment is used to realize the balance and corresponding positioning and fixing of the prefabricated cover beam segment on a single column (single column) for the implementation of subsequent processes.

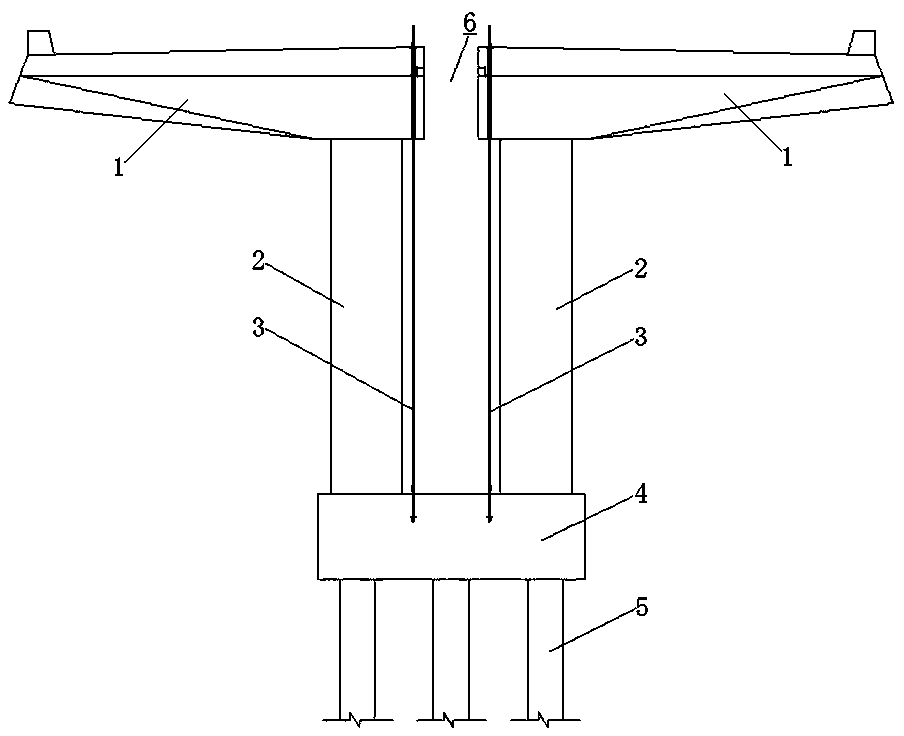

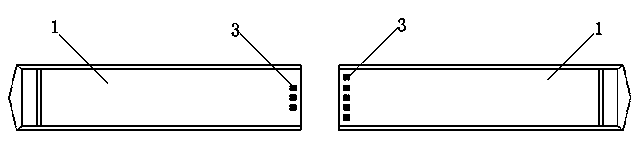

[0023] Such as figure 1 As shown, the bridge structure in this embodiment includes two sections of prefabricated cover beam sections 1, and a certain distance is reserved between the two sections of prefabricated cover beam sections 1 for the construction of concrete wet joint 6, so that the two sections of prefabricated cover beam sections 1 Section 1 is connected and fixed to form a whole to ensure the structural strength and stability of the cover beam. Two upright columns 2 are arranged below the two sections of prefabricated cover beam sections 1 respectively, and the two upright columns 2 correspond to each other and independently support the two sections of pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com