Coal bed methane gas ground treatment method

A coal seam gas and ground technology, which is applied in the field of energy mining, can solve the problems of poor coal seam gas control measures, collapsed holes or empty wells in horizontal wells, etc., and achieves the effects of solving gas control problems, good permeability enhancement effect and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

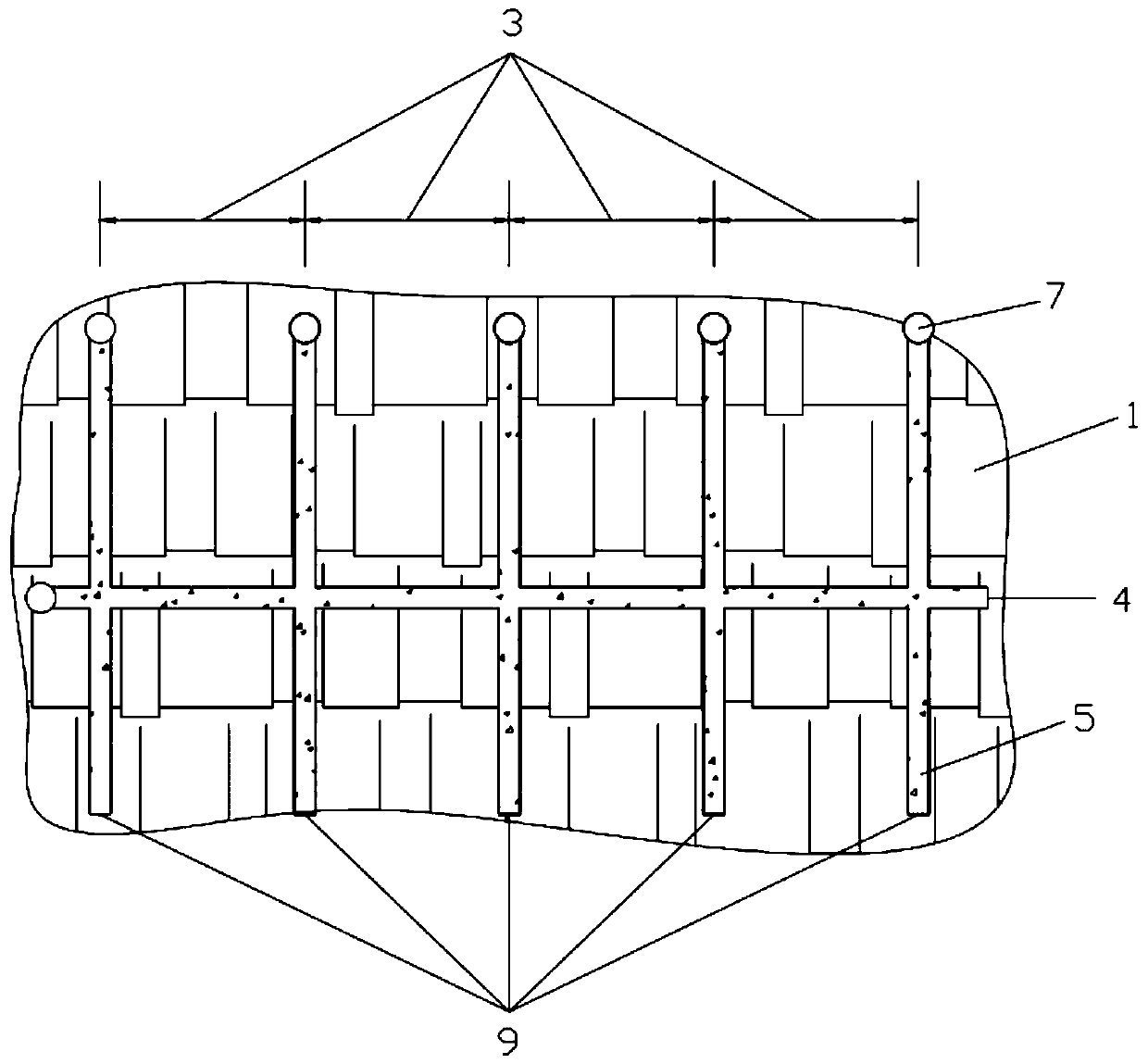

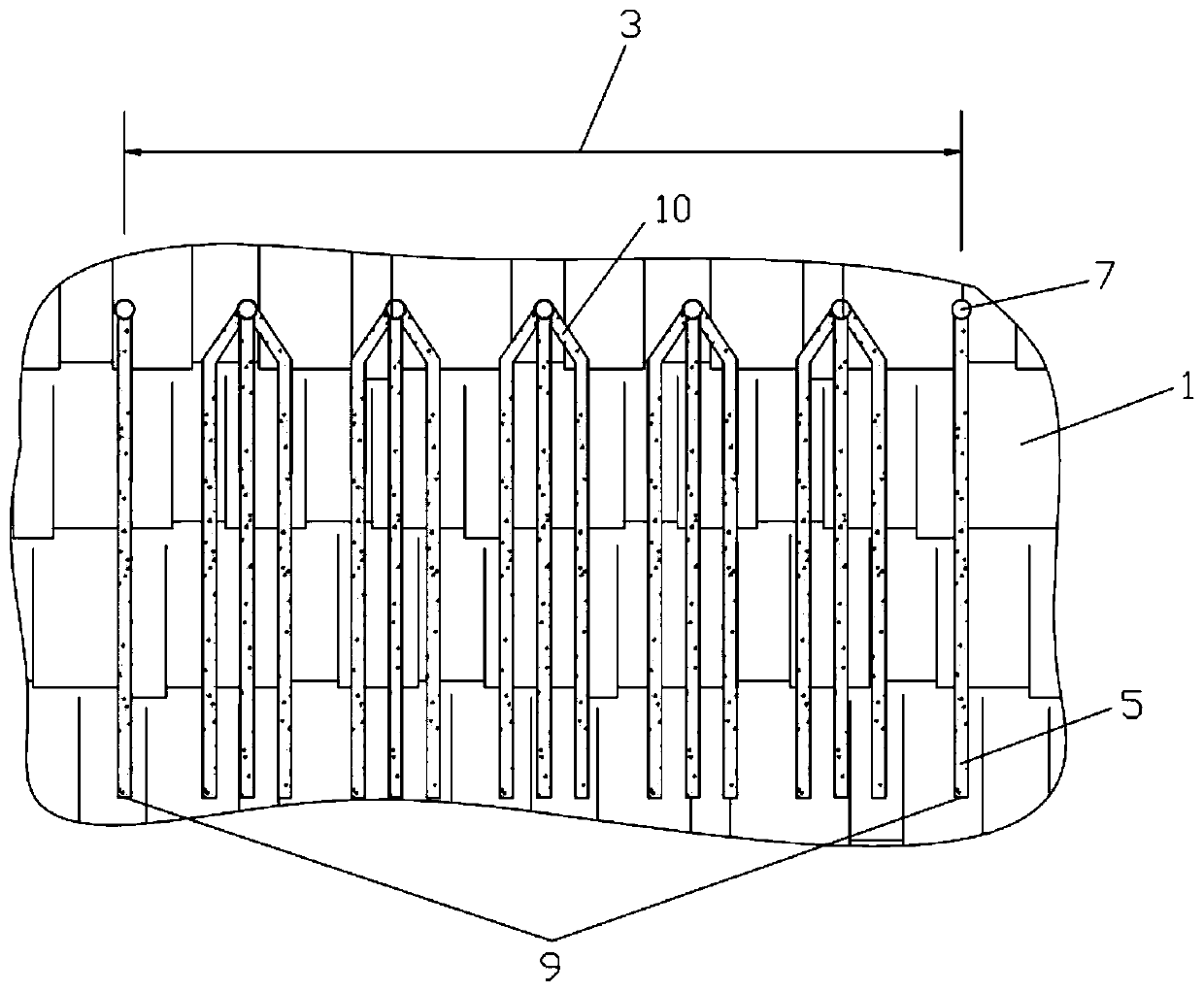

[0034] A coal seam gas ground control method, such as Figure 1 to Figure 5 shown, including the following steps:

[0035] S1, explore the range of the mine field for mining, and preset the layout route of the main road 4, the coal mining face 3 and the roadways 9 on both sides of the coal mining face 3 during mine mining;

[0036] Such as figure 1 As shown, according to the topographical characteristics of the mine field coal mine area and the various attribute parameters of the coal mine, the coal mining face 3 area during coal mining, as well as the layout routes of the roadways 9 and 4 on both sides of the coal mining face 3 are set .

[0037] S2, setting the wellbore track of the horizontal well 5 along the layout route of the main road 4 and the roadways 9 on both sides;

[0038] Set the wellbore trajectory and the wellh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com