Preparation method of ductile substrate material

A substrate and film material technology, applied in the field of ductile substrate material preparation, can solve the problems of unsustainable development and high production cost, and achieve the effects of good visible light transmittance, low cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

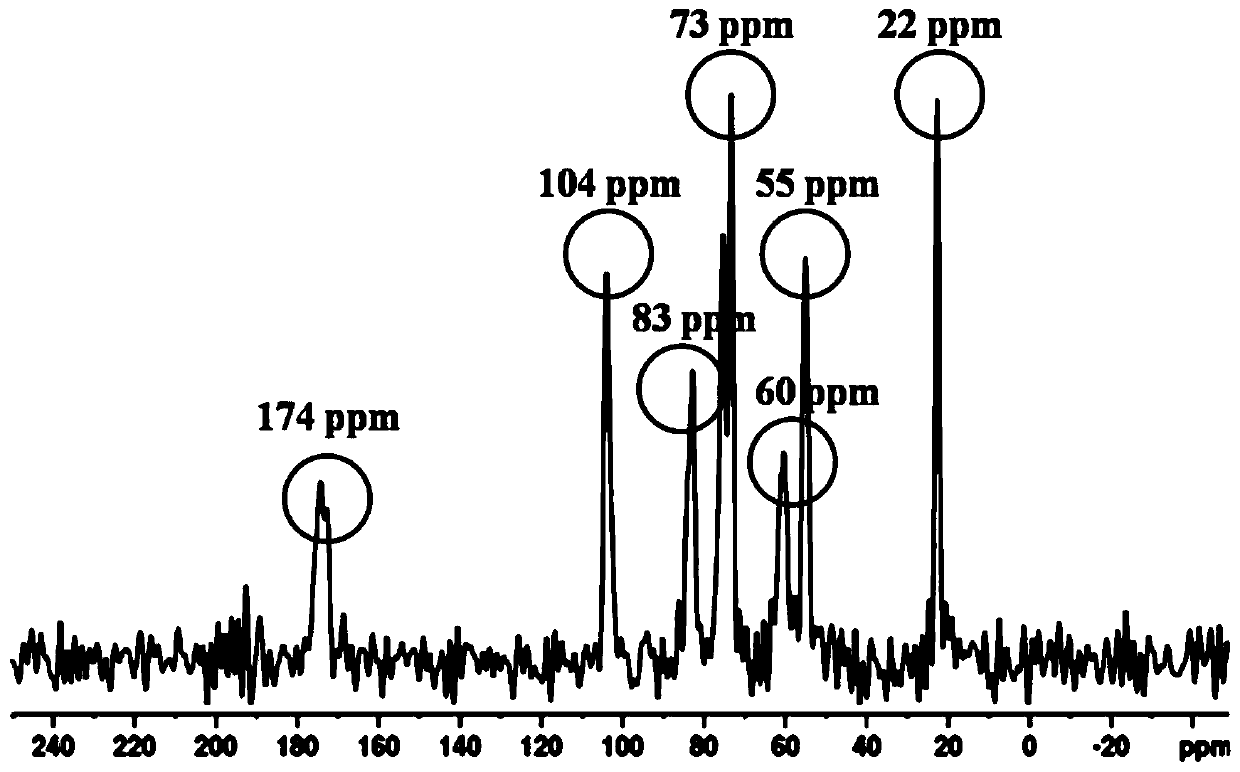

[0038] The application provides a method for preparing a ductile substrate material, which includes the following steps:

[0039] 1. Pulverizing step: drying the cicada slough to a constant weight, then crushing, extruding through a 1000-mesh sieve to obtain cicada slough powder;

[0040] One reaction step: transfer the cicada slough powder to a mixed solution of sodium iminodisuccinate, potassium persulfate and hydrogen peroxide, seal, heat and continuously stir, filter the product, and wash the filter residue with deionized water until neutral;

[0041] 1. Grinding step: transfer the filter residue into acetic acid solution, ultrasonically treat after grinding, and centrifuge to get the supernatant;

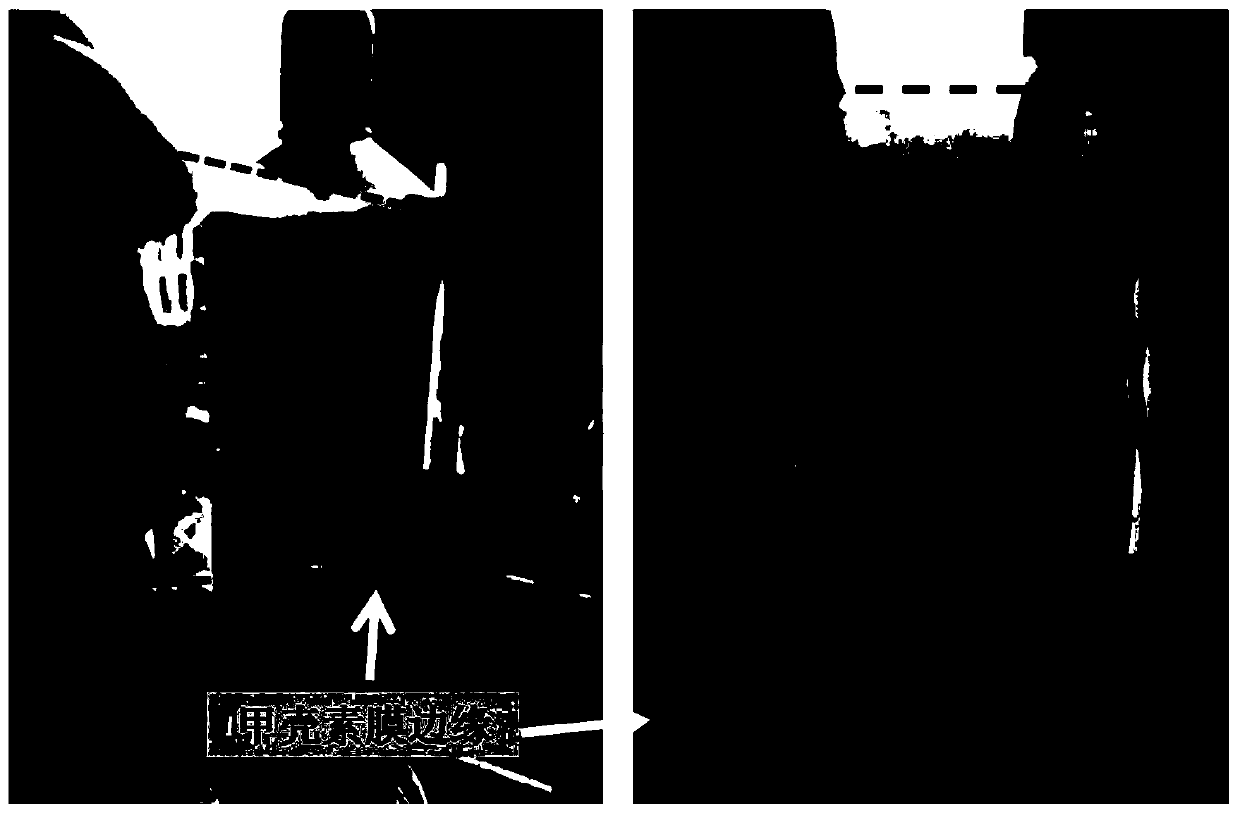

[0042] 1. Gelling step: Dilute the supernatant 10 times with deionized water, evaporate part of the water, and make a hydrogel.

[0043] The preparation method of the ductile substrate material described in this application includes the following restrictions:

[0044] a) the...

Embodiment 1

[0060] This embodiment provides a method for preparing a ductile substrate material, which includes the following steps:

[0061] 1. Pulverizing step: drying the cicada slough to a constant weight, then crushing, extruding through a 1000-mesh sieve to obtain cicada slough powder;

[0062] One reaction step: transfer the cicada slough powder to a mixed solution of sodium iminodisuccinate, potassium persulfate and hydrogen peroxide, seal, heat and continuously stir, filter the product, and wash the filter residue with deionized water until neutral;

[0063] 1. Grinding step: transfer the filter residue into acetic acid solution, ultrasonically treat after grinding, and centrifuge to get the supernatant;

[0064] 1. Gelling step: Dilute the supernatant 10 times with deionized water, evaporate part of the water, and make a hydrogel.

[0065] In this preferred embodiment, the pulverization in the pulverization step can be pulverized by an ultrafine pulverizer.

[0066] In this pr...

Embodiment 2

[0081] This embodiment provides a ductile substrate material, which is characterized in that the ductile substrate material is prepared by the method described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com