Automatic production device for medical gauze textile machine turning and sliding plate

A textile machine and gauze technology, which is applied to the field of automatic production devices for the flipping slide plate of a medical gauze textile machine, can solve the problems of high scrap rate, low work efficiency, and high production cost of the flip slide dial, and achieve the effect of reducing the accumulation of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

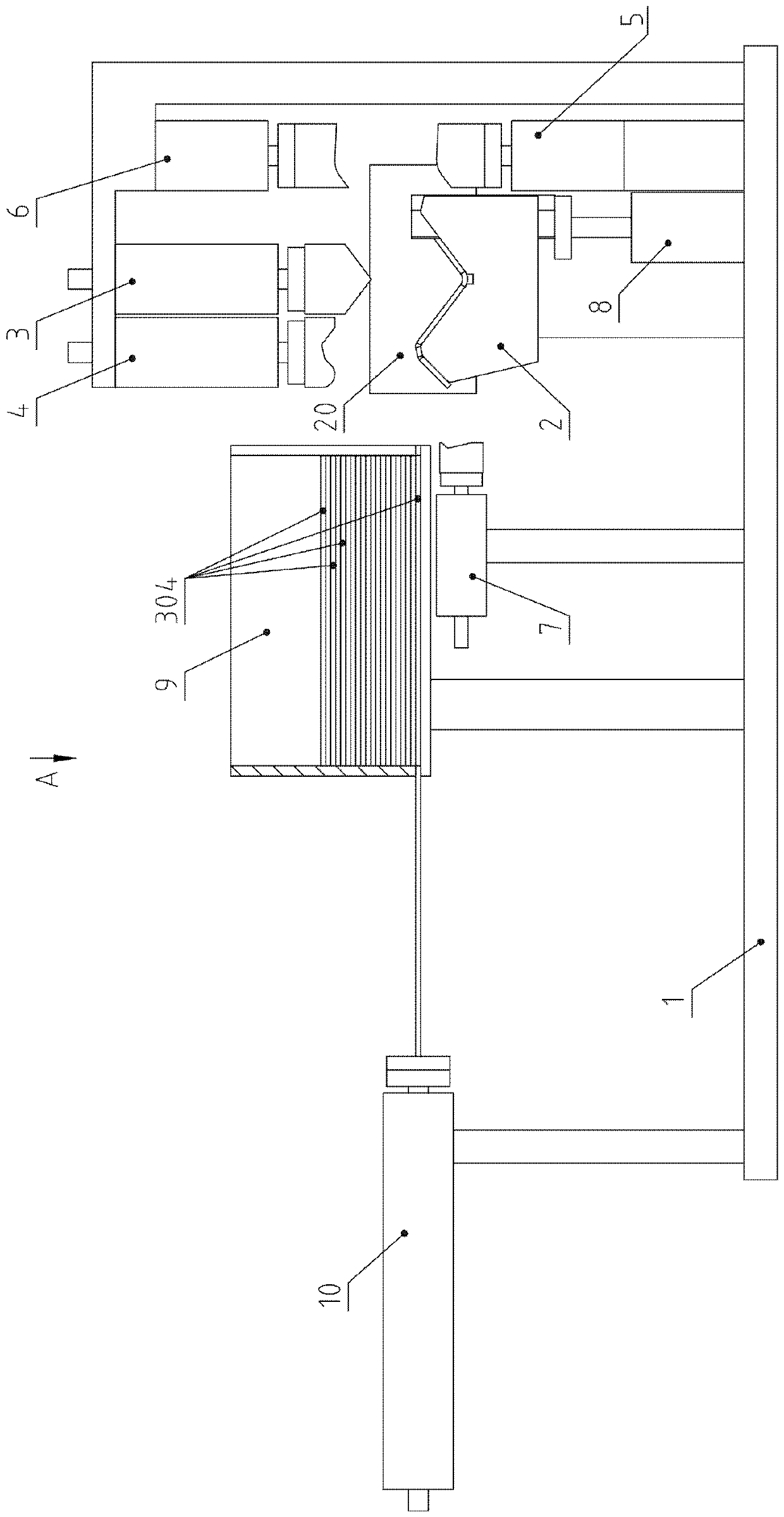

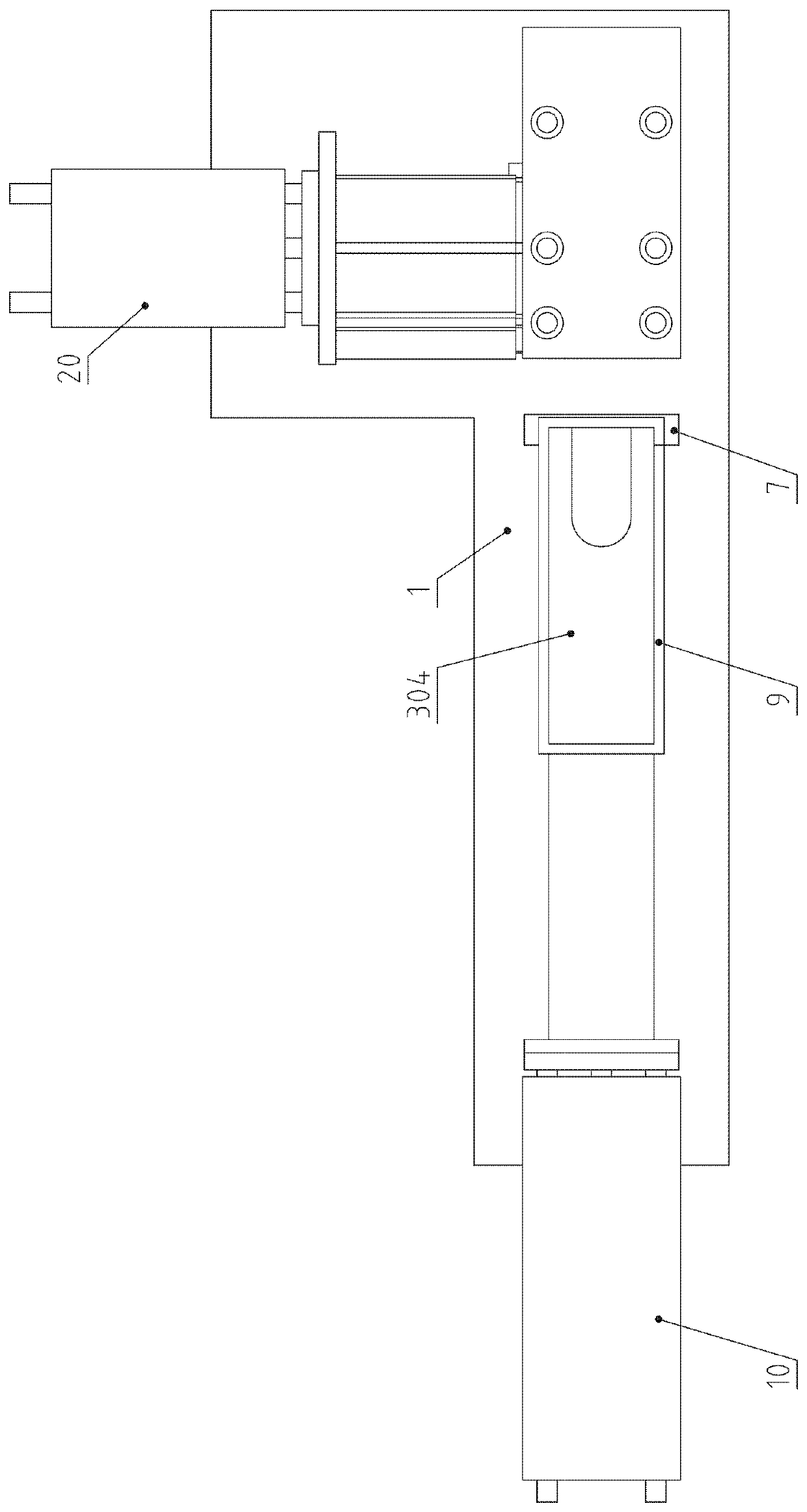

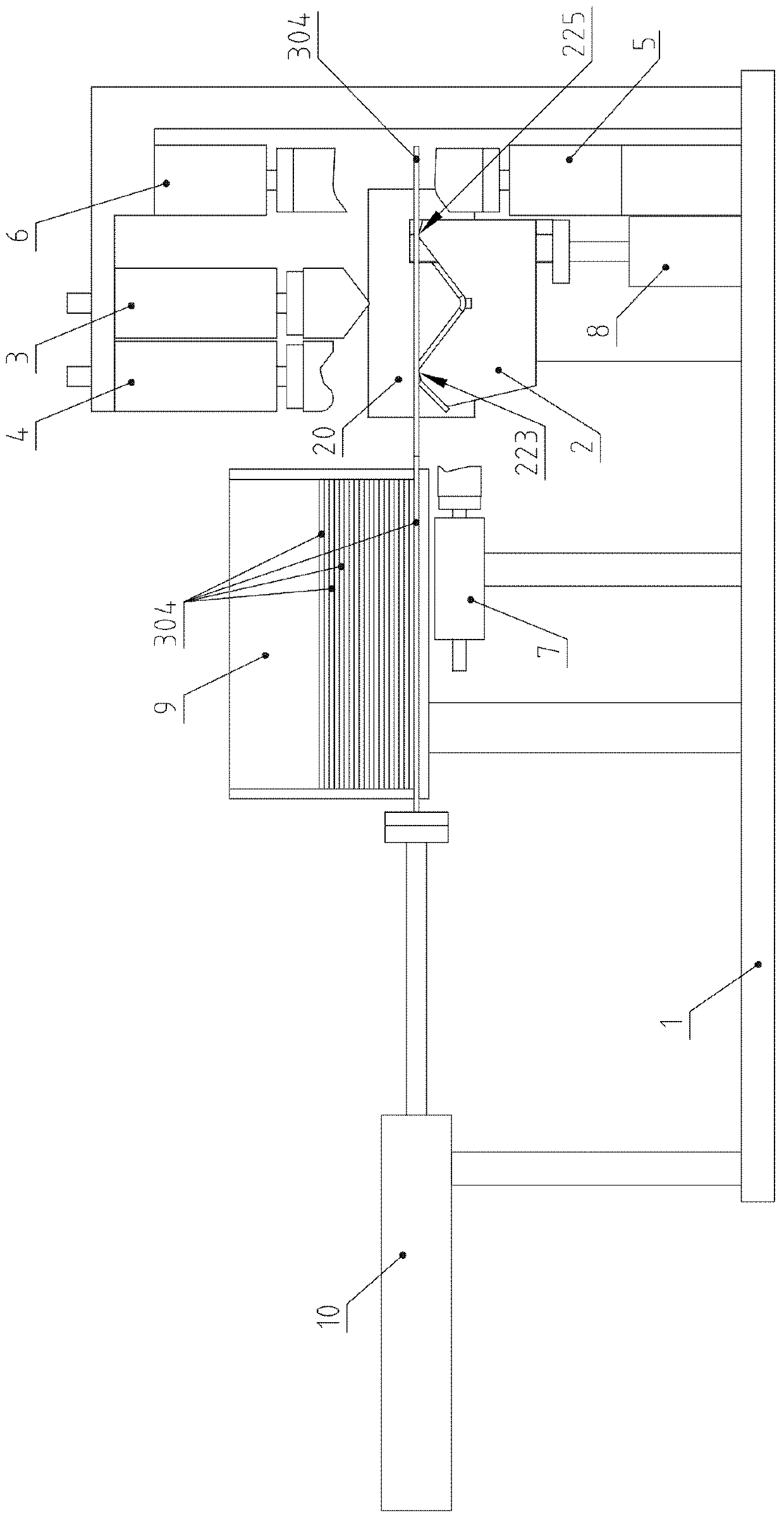

[0052] Example: see Figure 1 to Figure 18 .

[0053] An automatic production device for a medical gauze textile machine with a flip sliding plate, including a frame 1, a bottom mold 2, a bending four upper mold assembly 3, a bending two and three upper mold assembly 4, and a bending five lower mold assembly Part 5, bending five upper mold assembly 6, bending one rear mold assembly 7, sliding slot positioning assembly 8, hopper 9, feeding assembly 10 and return assembly 20;

[0054] The bottom mold 2 includes six planes perpendicular to the left and right directions, and the six planes of the bottom mold 2 are bottom mold plane one 211, bottom mold plane two 212, bottom mold plane three 213, bottom mold plane 213, and bottom mold plane from back to bottom to back to front. Plane 4 214, bottom mold plane 5 215 and bottom mold plane 6 216; the intersection of bottom mold plane 1 211 and bottom mold plane 2 212 is flute edge 1 221; the intersection of bottom mold plane 2 212 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com