A robot grinding equipment and method for the surface of a rotating body

A robot and rotary body technology, applied in machine tools, grinding drives, grinding/polishing equipment designed for grinding the rotating surface of workpieces, etc., can solve the problems of high skill requirements, low automation and high labor costs for grinding personnel. , to avoid inefficient processes, improve grinding quality, avoid vibration and shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

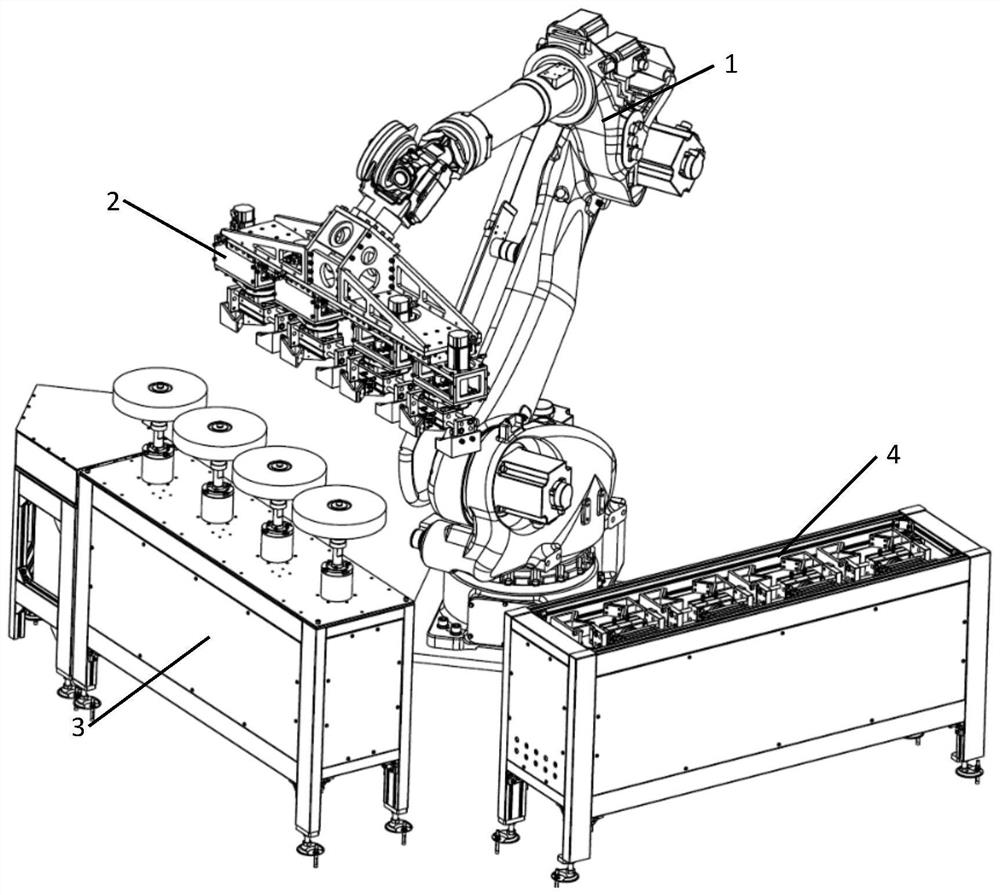

[0021] Taking grinding four workpieces at the same time as an example, a schematic diagram of a robot grinding equipment for the surface of a rotating body is as follows: figure 1 As shown, it includes: a six-degree-of-freedom industrial robot 1; four sets of compliance devices and rotary pneumatic clamps are installed at the end of the robot through connecting tooling 2; a horizontal grinding machine station 3 with four grinding heads; four sets of clamp changing devices Changing station 4.

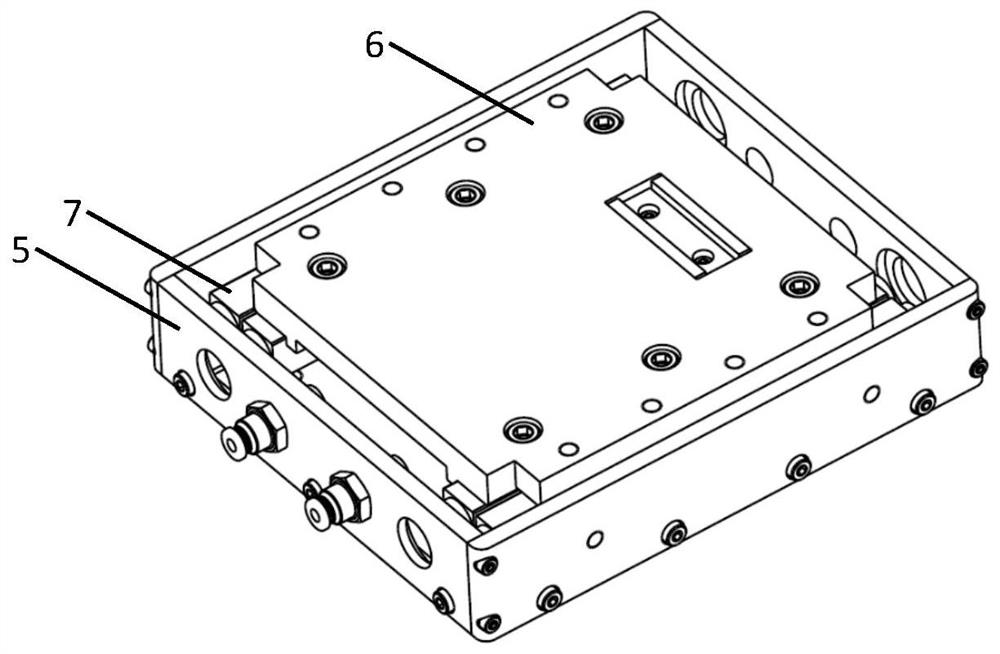

[0022] The compliance device such as figure 2 As shown: the fixed end 5 and the movable end 6 are connected by a linear guide rail 7, the two parts can move linearly in a single direction, and a cylinder is installed inside, and the force of the relative movement is controlled by adjusting the air pressure of the cylinder.

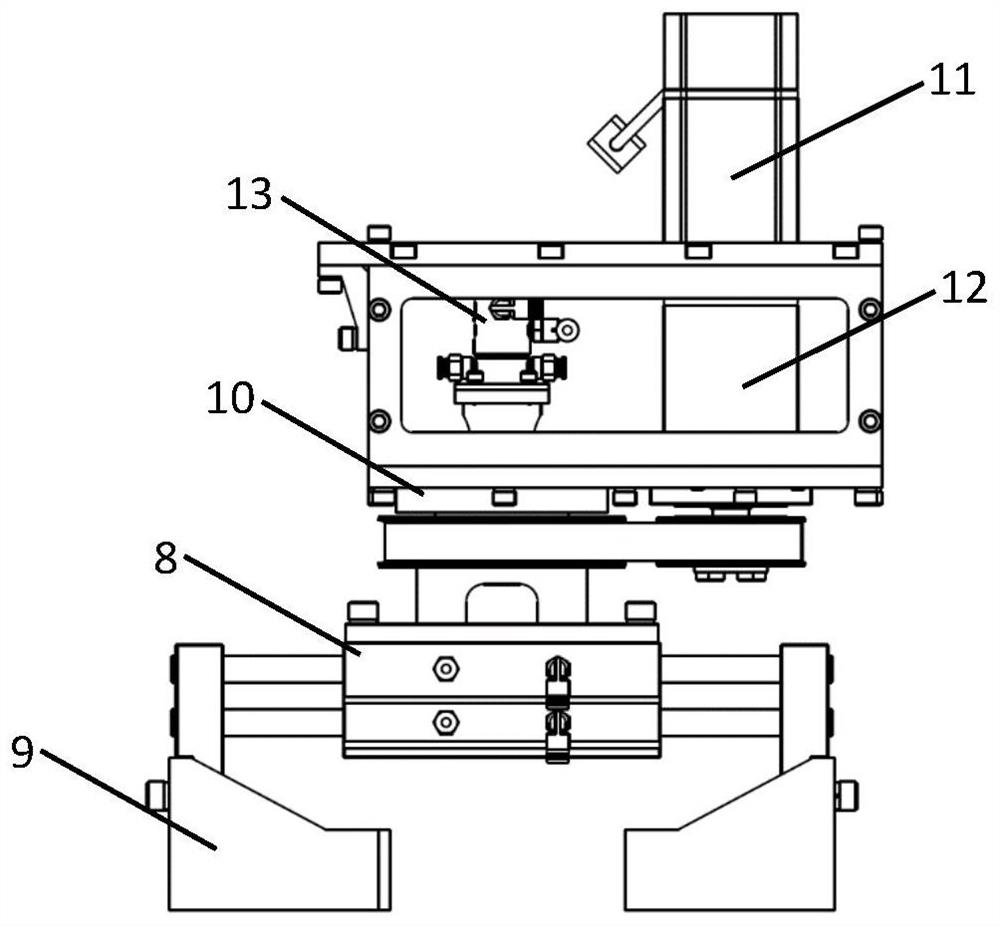

[0023] The rotary pneumatic clamp suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com