Sprayable anti-drying clay sculpture printing machine

A technology for printers and clay sculptures, which is applied in the field of sprayable and anti-dry cracking clay sculpture printers, can solve the problems of high labor intensity, cumbersome production process, and easy occurrence of dry cracking, and achieves the effect of reducing labor intensity, good spraying effect, and preventing dry cracking of clay sculptures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

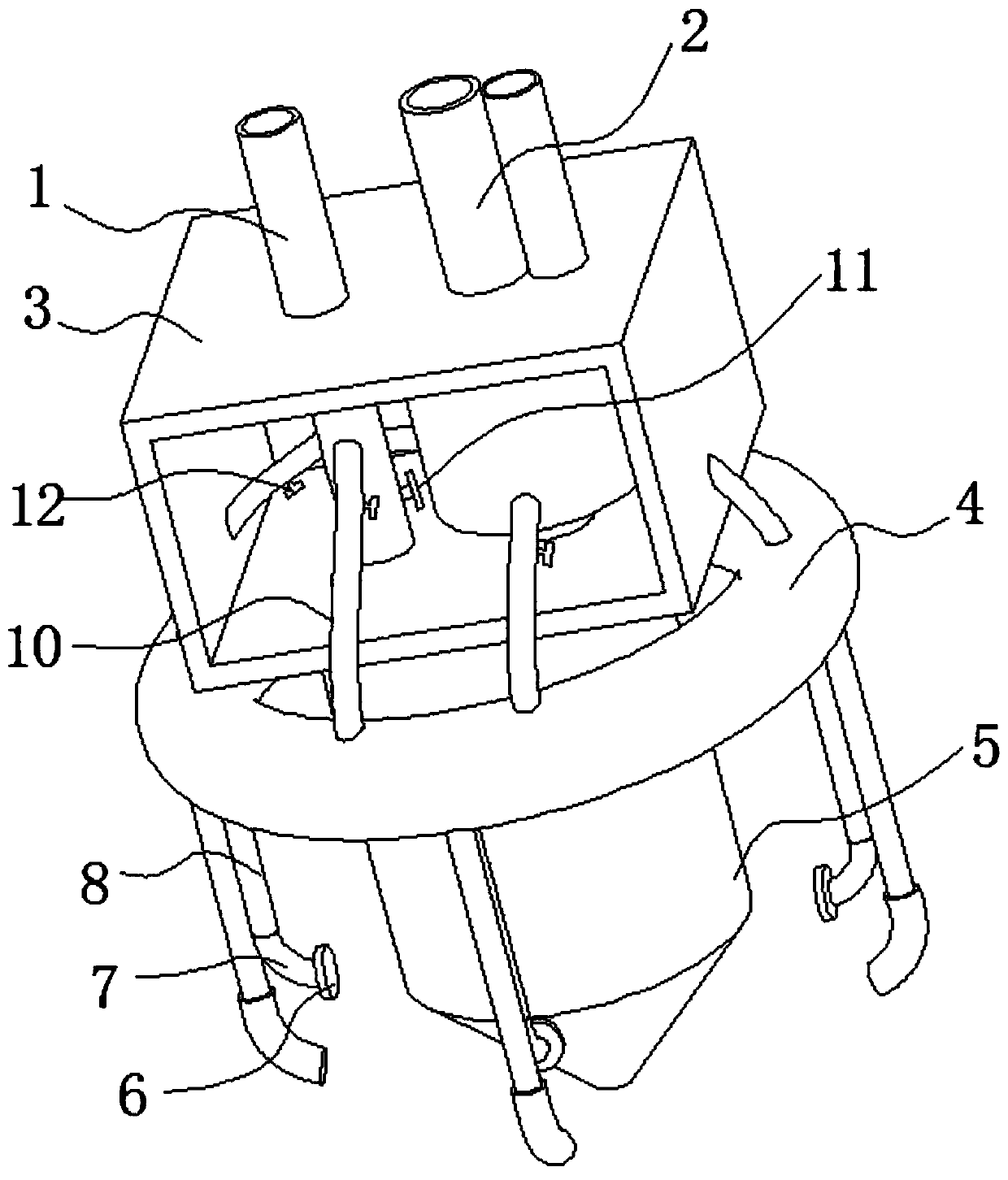

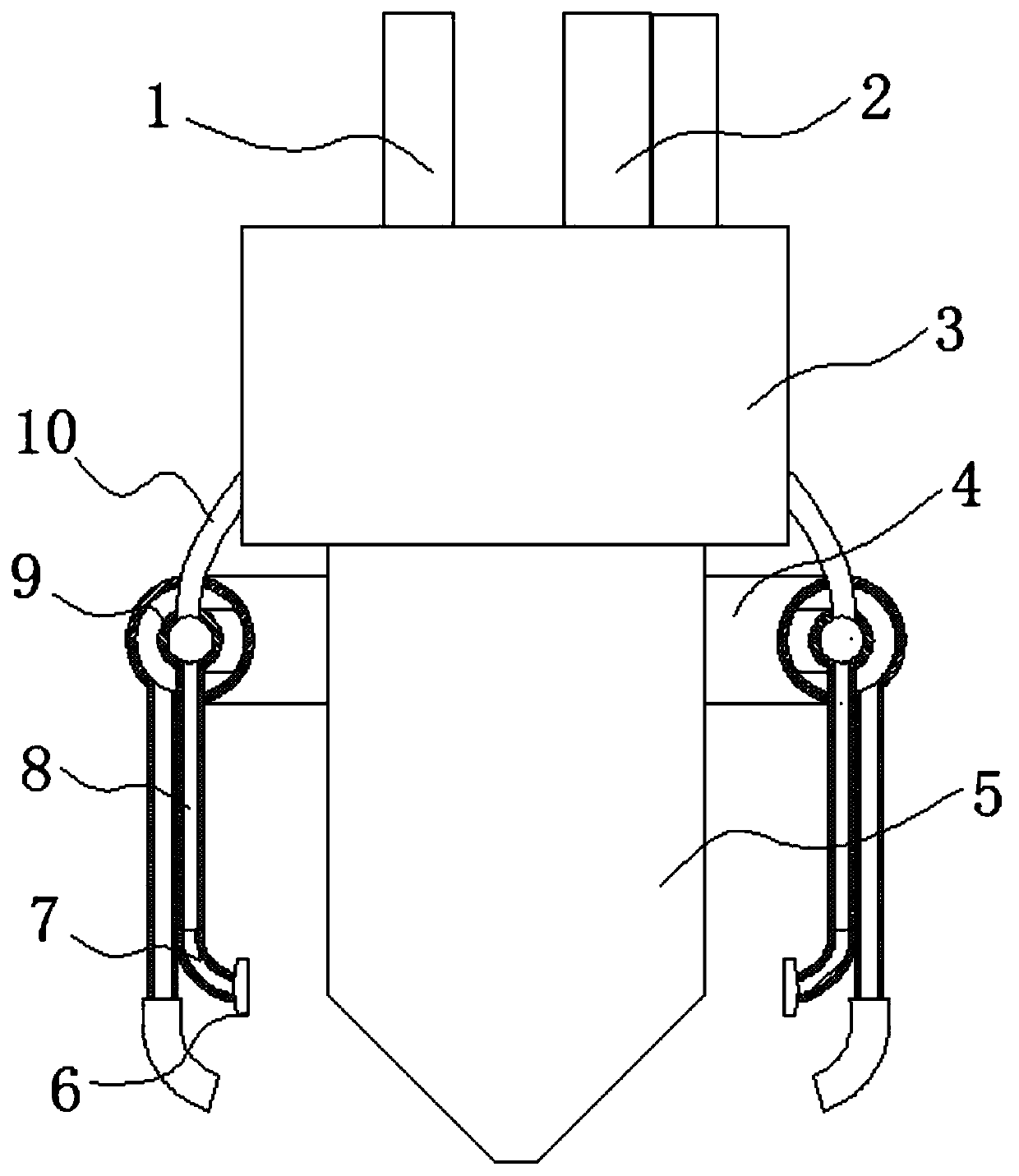

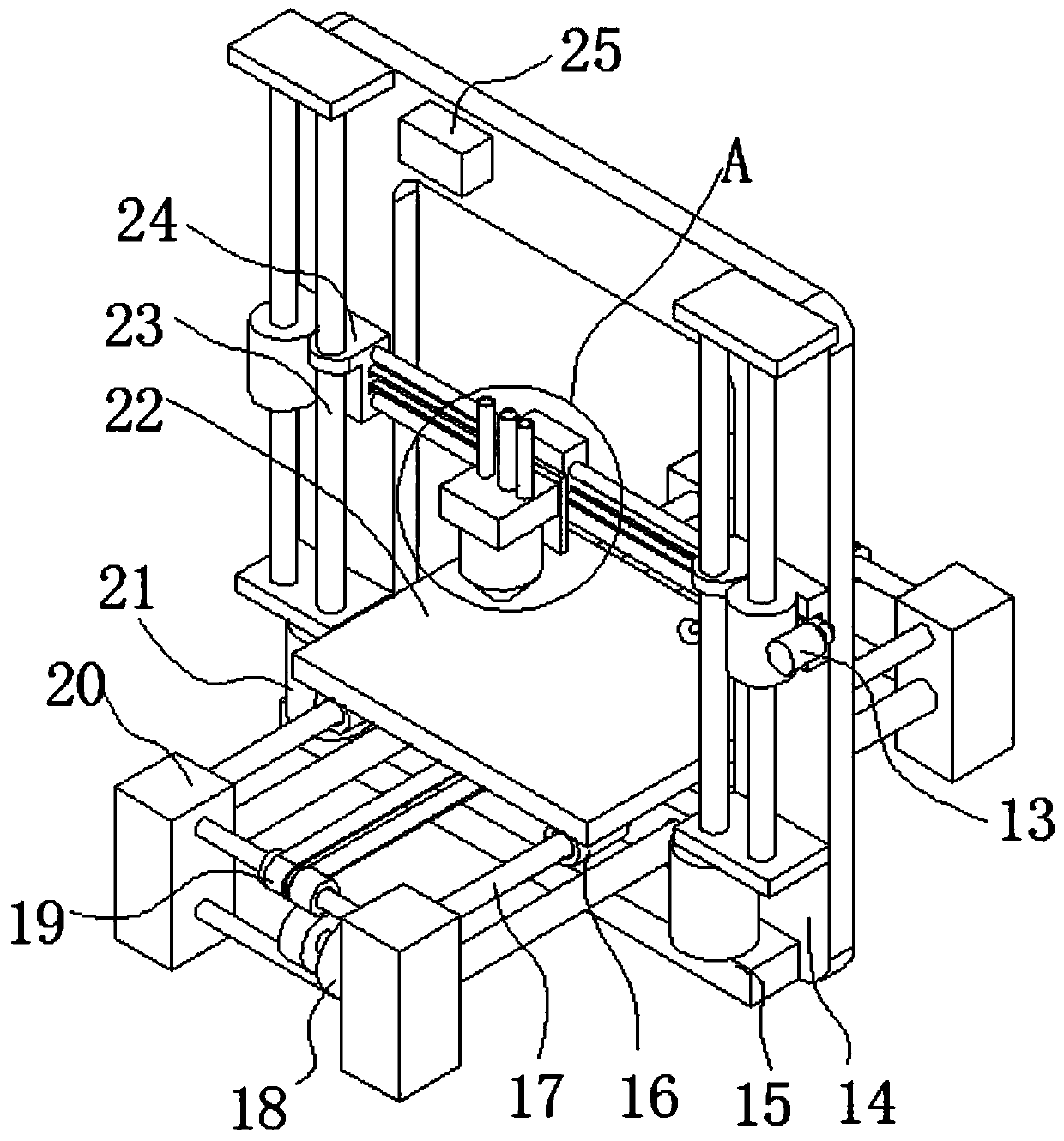

[0026] Reference Figure 1-4 , A sprayable anti-dry-cracking clay printer, including a printing stand, a controller 25 and a material extrusion head 5. The controller 25 and the material extrusion head 5 are both connected to the printing frame, and the material extrusion head 5 passes through a connection box 3 The water inlet pipe 1 and the feed pipe 2 are connected. A spray ring pipe 9 is sleeved under the connection box 3. A plurality of spray pipes 8 are connected to the lower side of the spray ring pipe 9, and the lower end of the spray pipe 8 is connected with a spray head 6 through an elbow 7 , The spray ring tube 9 is connected with a water inlet arc tube 10, and the end of the water inlet arc tube 10 away from the spray ring tube 9 is connected to the water inlet pipe 1. When the printer is printing, it needs to pass through the water inlet tube 1 and the feed tube 2 For water and material feeding, the printing frame moves the material extruding head 5 and then discha...

Embodiment 2

[0028] Reference Figure 1-4 , A sprayable anti-dry-cracking clay printer, which is basically the same as embodiment 1, except that a first solenoid valve 12 is connected to the water inlet arc pipe 10, and a second solenoid valve 11 is connected to the water inlet pipe 1 The second solenoid valve 11 is located at the lower end of the connection between the water inlet arc pipe 10 and the water inlet pipe 1. Both the first solenoid valve 12 and the second solenoid valve 11 are electrically connected to the controller 25, through the first solenoid valve 12 and the The second solenoid valve 11 is convenient to control the opening and closing of the water inlet arc pipe 10 and the water inlet pipe 1 to supply water to the material extrusion head 5.

[0029] The water inlet arc tube 10 is sheathed with a heating ring tube 4, which can heat the water inlet arc tube 10, ensuring that the thermal spray is sprayed in a low temperature environment, and effectively preventing the spray te...

Embodiment 3

[0031] Reference Figure 1-4 , A sprayable anti-dry-cracking clay printer, including a printing stand, a controller 25 and a material extrusion head 5. The controller 25 and the material extrusion head 5 are both connected to the printing frame, and the material extrusion head 5 passes through a connection box 3 The water inlet pipe 1 and the feed pipe 2 are connected. A spray ring pipe 9 is sleeved under the connection box 3. A plurality of spray pipes 8 are connected to the lower side of the spray ring pipe 9, and the lower end of the spray pipe 8 is connected with a spray head 6 through an elbow 7 , The spray ring tube 9 is connected with a water inlet arc tube 10, and the end of the water inlet arc tube 10 away from the spray ring tube 9 is connected to the water inlet pipe 1. When the printer is printing, it needs to pass through the water inlet tube 1 and the feed tube 2 For water and material feeding, the printing frame moves the material extruding head 5 and then discha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap