Manufacture method for Tibetan tea liquor

A production method and technology of Tibetan tea, applied in the preparation of alcoholic beverages, etc., can solve the problems of inability to dissolve effective ingredients and low quality of Tibetan tea wine, and achieve the effects of enriching tea wine varieties, promoting metabolism, and eliminating fatigue and tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

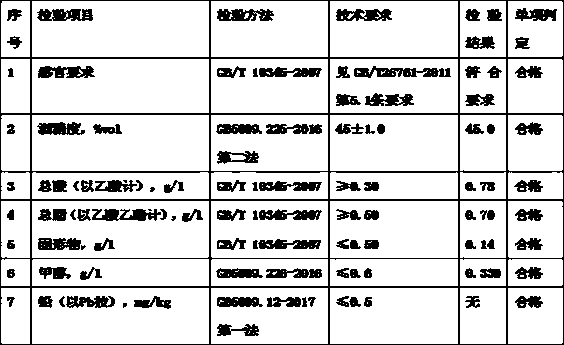

Embodiment 1

[0030] A method for making Tibetan tea wine, comprising the following steps in sequence:

[0031] Raw material preparation: Soak sorghum, corn and rice in warm water at 85°C for 16 hours, then filter to obtain soaked sorghum, corn and rice, and then soak the sorghum, corn and rice in a weight percentage of 5:4: The ratio of 1 is mixed and stirred evenly to obtain the raw materials;

[0032] Cooking: First place a layer of coarse bran with a thickness of 2cm in the digester, then pour the raw materials into the digester and cook for 1 hour, until there are no raw cores inside, slight blooms on the outside, and the raw materials are completely cooked;

[0033] Measure the water: add water at a temperature of 80°C to the cooked raw materials until the raw materials absorb water thoroughly and do not flow out;

[0034] Stacking: Place the raw materials that have absorbed water thoroughly on the stacking board for natural cooling, the stacking thickness is 8cm, and the stacking ti...

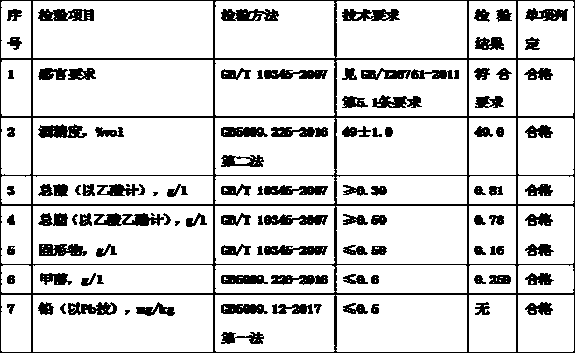

Embodiment 2

[0048] A method for making Tibetan tea wine, comprising the following steps in sequence:

[0049] Raw material preparation: Soak sorghum, corn and rice in warm water at 85°C for 17 hours, then filter to obtain soaked sorghum, corn and rice, and then soak the sorghum, corn and rice in a weight percentage of 7:5: The ratio of 2 is mixed and stirred evenly to obtain raw materials;

[0050] Cooking: First place a layer of coarse bran with a thickness of 3cm in the digester, then pour the raw materials into the digester and cook for 1.5 hours, until there are no raw cores inside, slight flowering on the outside, and the raw materials are completely cooked;

[0051] Measure the water: add water at a temperature of 85°C to the cooked raw materials until the raw materials absorb water thoroughly and do not flow out;

[0052] Stacking: Put the raw materials that have absorbed water thoroughly on the stacking board for natural cooling, the stacking thickness is 10cm, and the stacking t...

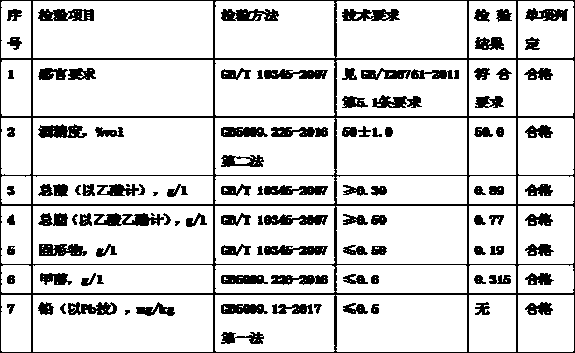

Embodiment 3

[0066] A method for making Tibetan tea wine, comprising the following steps in sequence:

[0067] Raw material preparation: Soak sorghum, corn and rice in warm water at 88°C for 17 hours, then filter to obtain soaked sorghum, corn and rice, and then soak the sorghum, corn and rice in a weight percentage of 10:7: The ratio of 2 is mixed and stirred evenly to obtain raw materials;

[0068] Cooking: first place a layer of coarse bran with a thickness of 4cm in the digester, then pour the raw materials into the digester and cook for 2.5 hours, until there is no raw core inside, the outside is slightly flowered, and the raw materials are completely cooked;

[0069] Measure the water: add water at a temperature of 88°C to the cooked raw materials until the raw materials absorb water thoroughly and do not flow out;

[0070] Stacking: Put the thoroughly water-absorbed raw materials on the stacking board for natural cooling, the stacking thickness is 13cm, and the stacking time is 45 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com