A cooling cycle system

A circulation system and cold-carrying technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of lack of reliable low-flow low-temperature circulation pumps, etc., and achieve the effect of easy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

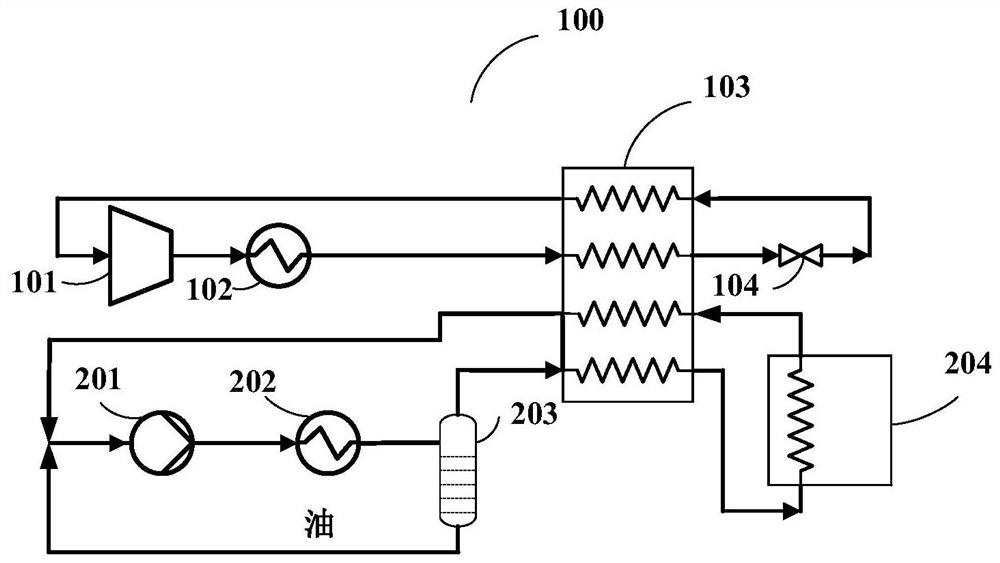

[0023] see figure 1 , is a schematic structural diagram of a load-cooling cycle system provided by Embodiment 1 of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown, and the details are as follows.

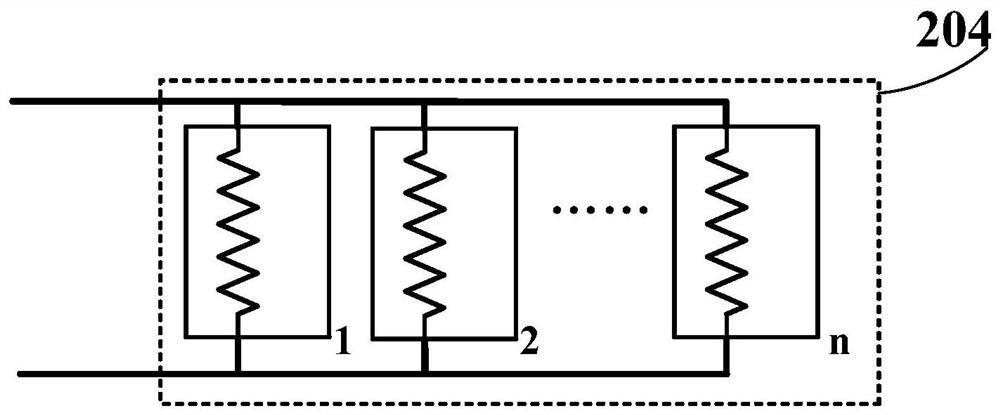

[0024] The load cooling cycle system 100 provided by the present invention includes: a mixed working medium refrigeration cycle circuit and a load cooling cycle circuit; the mixed working medium refrigeration circuit includes a mixed working medium compressor (101), a mixed working medium condenser (102), regenerative heat exchanger (103), mixed working medium throttle valve (104); the brine-cooled circulation loop includes brine-driven pump (201), brine condenser (202), brine precision oil separation device (203) and user side (204); wherein:

[0025] The high-pressure refrigerant outlet of the mixed working medium compressor (101) is connected to the high-pressure refrigerant inlet of the mixed...

Embodiment 2

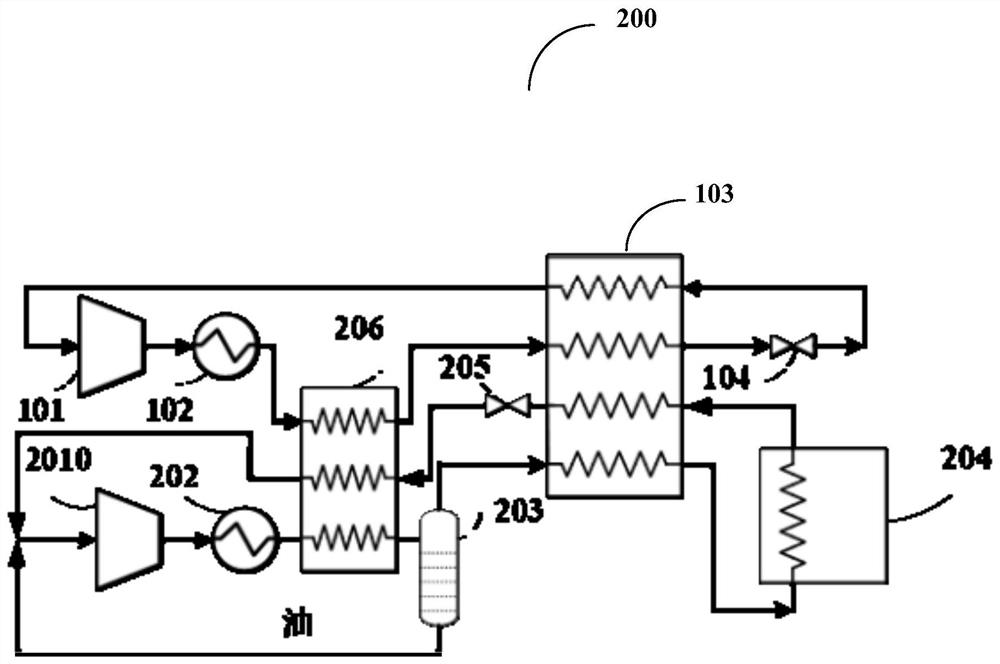

[0031] see figure 2 , is a schematic structural diagram of a load-cooling cycle system provided by Embodiment 2 of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown, and the details are as follows.

[0032] A cooling cycle system 200 provided by the present invention includes: a mixed working medium refrigeration cycle and a cooling cycle; the mixed working medium refrigeration circuit includes a mixed working medium compressor (101), a mixed working medium condenser (102 ), a recuperative heat exchanger (103), a mixed working medium throttle valve (104); Refrigerant precooling heat exchanger (206), brine precision oil separator (203) and user side (204); where:

[0033] The high-pressure refrigerant outlet of the mixed working medium compressor (101) is connected to the high-pressure refrigerant inlet of the mixed working medium condenser (102), and the high-pressure refrigerant outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com