Method for measuring in-situ mechanical properties of gel particles

A technology of gel particles and mechanical properties, applied in the field of measuring the in-situ mechanical properties of gel particles, can solve the problems of uneven force, time-consuming, and cannot be used as a conventional performance evaluation method, and achieves the effect of a wide range of applicable objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

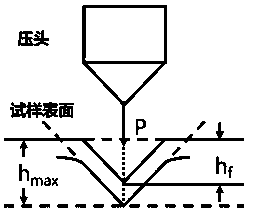

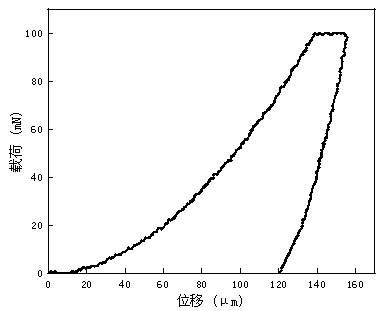

[0044] This embodiment mainly tests the modulus of elasticity of gel particle oil displacement agent PPG, comprises the steps:

[0045] (1) Preparation of PPG dispersion system:

[0046]Accurately weigh 5g of PPG oil displacement agent sample (100-150 mesh), accurate to 0.0001g. Weigh 1L of simulated formation water into a 2000mL beaker. The formation water is composed of the following components and their contents: sodium sulfate 69.6ppm, sodium chloride 6191ppm, anhydrous calcium chloride 241.4ppm, magnesium chloride hexahydrate 351.4ppm, and the rest ionized water. Turn on the constant speed stirrer and slowly add the sample along the wall of the vortex at 400r / min for 30s, then stir at a stirring rate of 500r / min for 2 hours, the PPG is fully swollen and a dispersed system is formed.

[0047] (2) Separation of PPG gel particles:

[0048] Take a funnel, put the folded filter paper into the funnel and moisten it with simulated formation water to ensure that the filter pap...

Embodiment 2

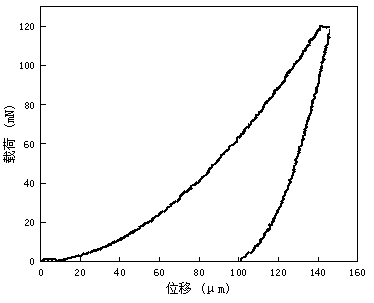

[0056] In this example, the elastic modulus of the viscoelastic particles with a solid core structure of fly ash is tested. The sample size of the viscoelastic particles with a solid core structure of fly ash is 100-150 mesh. The preparation of the dispersion system, the separation and fixation of the viscoelastic particles, etc. Same as example 1, the instrument used is Hisilicon TI 980 TriboIndenter nano-indenter, firstly use SPM in-situ imaging technology to obtain the morphology of the sample to be tested, and determine the position of the indentation test point. Select the Berkovich diamond indenter, use the quasi-static indentation method to conduct nano-indentation test on the gel particles, select the load control mode, the maximum load is 120mN, the loading and unloading time is 25s, and the holding time at the maximum load is 10s. Start the indentation test, and obtain the force-displacement curve of displacement changing with load.

[0057] The data processing metho...

Embodiment 3

[0059] In this example, the plastic parameters and elastic modulus of the viscoelastic particles with a solid core structure of wood fibers are tested. The sample size of the viscoelastic particles with a solid core structure of wood fibers is 100-150 mesh, the preparation of the dispersion system, the separation and fixation of the viscoelastic particles, etc. The operation is the same as in Example 1, and the instrument used is Hisilicon TI 980 TriboIndenter nano-indenter. First, the SPM in-situ imaging technology is used to obtain the morphology of the sample to be tested, and the position of the indentation test point is determined. Select the Berkovich diamond indenter, use the quasi-static indentation method to conduct nano-indentation test on the gel particles, select the load control mode, the maximum load is 110mN, the loading and unloading time is 30s, and the holding time at the maximum load is 5s. Start the indentation test, and obtain the force-displacement curve o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com