Liquid metal composite oscillation heat pipe type thermal temperature difference power generation and refrigeration radiator

A liquid metal and oscillating heat pipe technology, which is applied in the fields of electric solid devices, generators/motors, semiconductor/solid device components, etc., can solve the problems of complex structure, low adaptability of electronic equipment, and restricted heat transfer performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

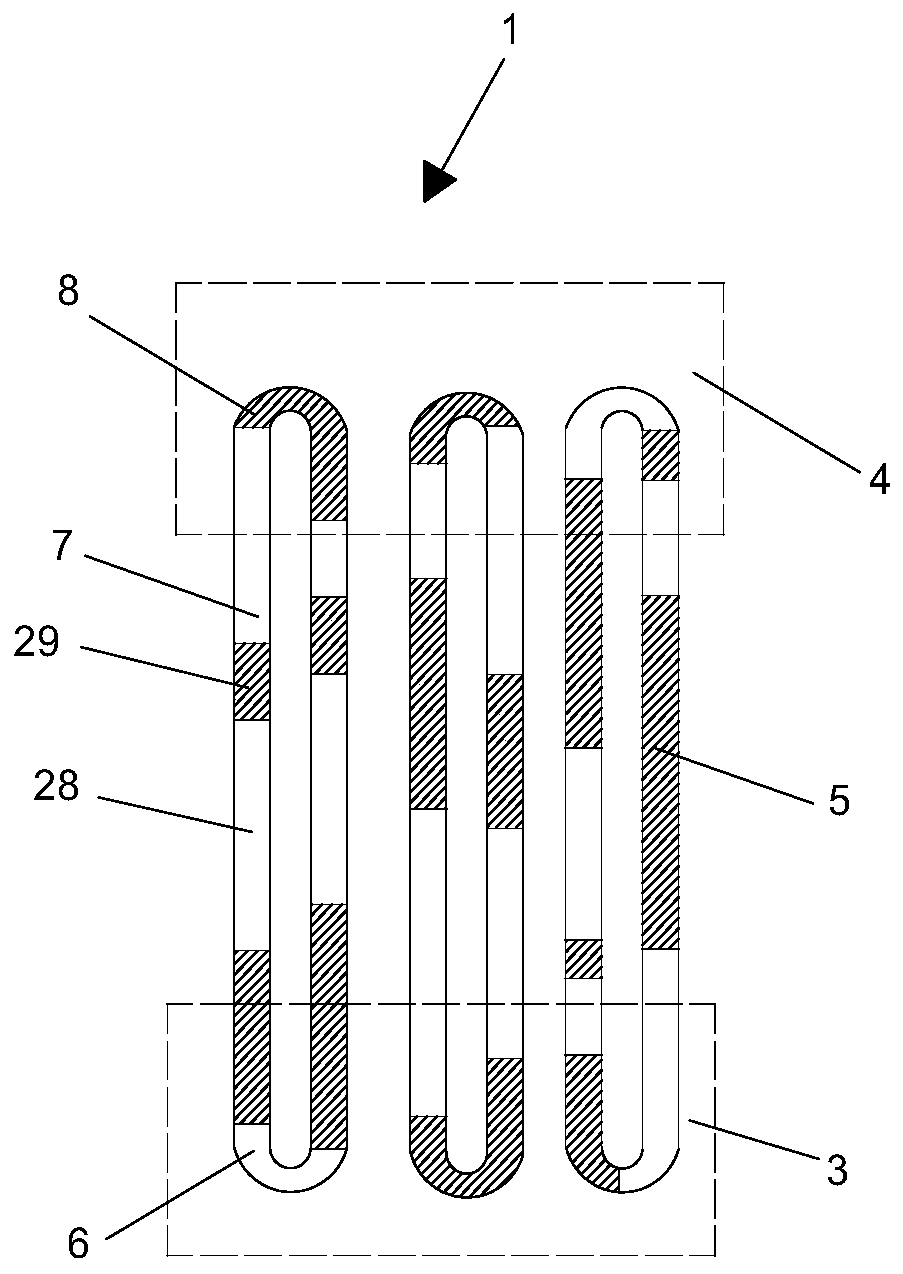

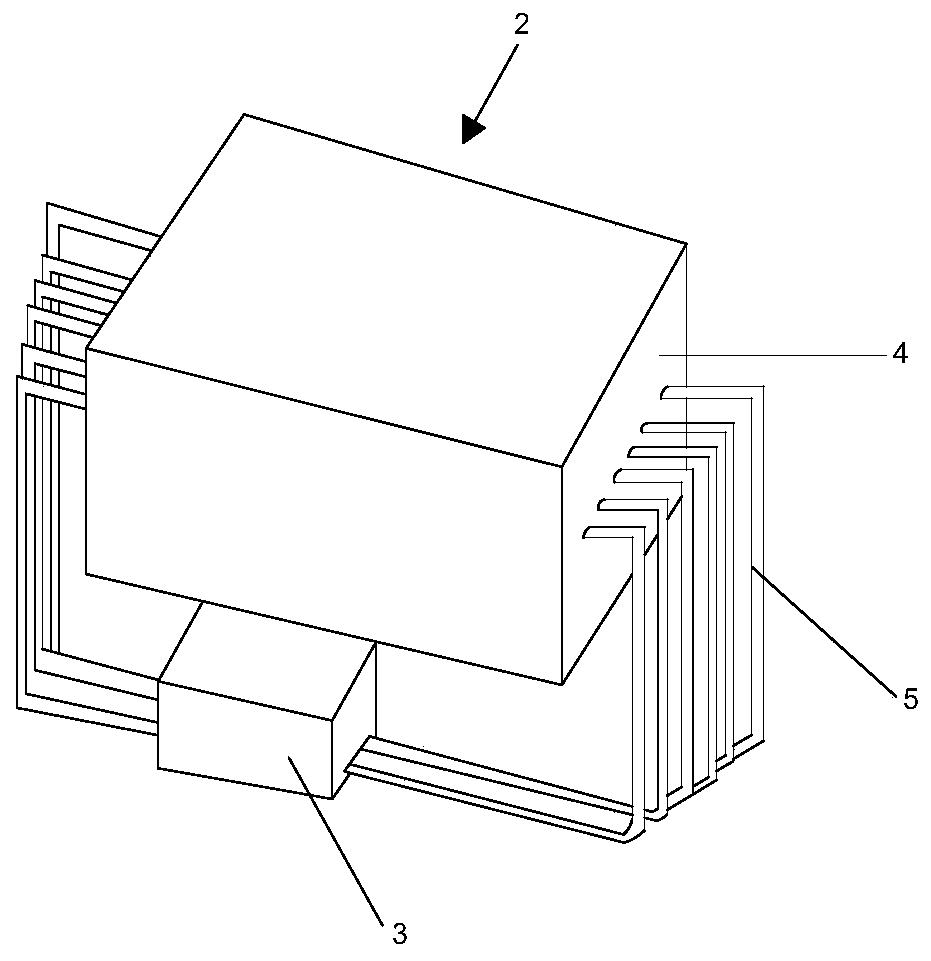

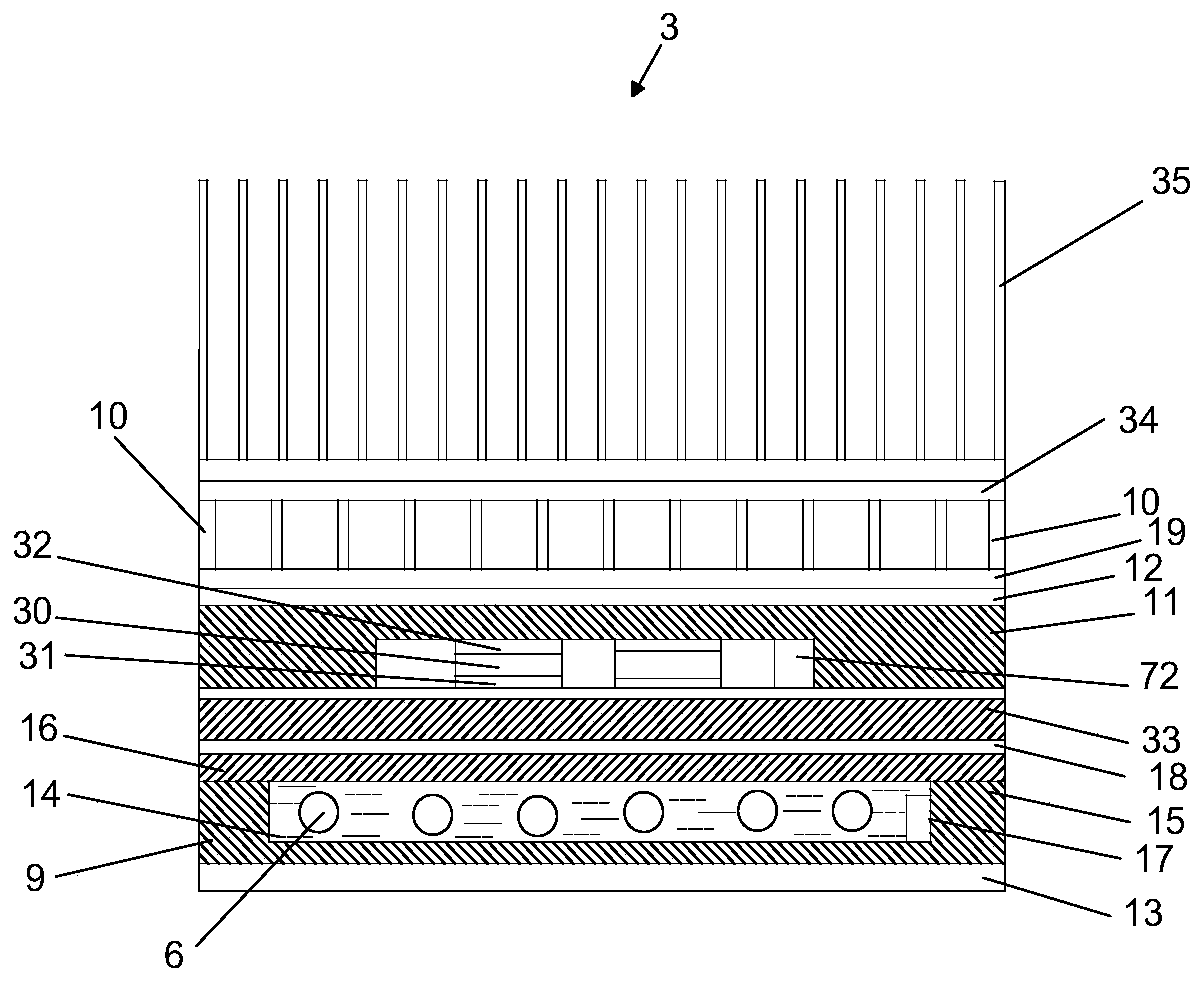

[0041] This embodiment 1 adopts liquid metal composite O-shape parallel oscillating heat pipe type thermal temperature difference power generation and cooling radiator

[0042] Example 1: The liquid metal composite O-shaped parallel oscillating heat pipe type thermal temperature difference power generation and refrigeration radiator 1 of the present invention is shown in the schematic diagram of the working structure. figure 1 ; The liquid metal composite O-shaped parallel oscillating heat pipe type thermal temperature difference power generation and cooling radiator 2 main structural schematic diagrams of the present invention are shown in figure 2 ; Liquid metal composite O-shaped parallel oscillating heat pipe type thermal thermoelectric generator 3 structural representations of the present invention are shown in image 3 ; Liquid metal composite O-shaped parallel oscillating heat pipe type heat temperature difference refrigerator 4 structural schematic diagrams of the pre...

Embodiment 2

[0053] This embodiment 2 adopts liquid metal composite serpentine loop oscillating heat pipe type thermal temperature difference power generation and cooling radiator

[0054] Example 2: The liquid metal composite serpentine loop oscillating heat pipe type thermal temperature difference power generation and cooling radiator 38 working structure schematic diagram of the present invention is shown in Figure 5 ; Liquid metal composite serpentine loop oscillating heat pipe type thermal thermoelectric generator 39 structural schematic diagrams of the present invention are shown in Image 6 ; Liquid metal composite serpentine loop oscillating heat pipe type thermal temperature difference refrigerator 40 structural schematic diagram of the present invention is shown in Figure 7 .

[0055] Embodiment 2 Liquid metal composite serpentine circuit oscillating heat pipe type thermal temperature difference power generation and cooling radiator 38, including: liquid metal composite serpen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com